A multi-stage drawing method for bendable flexible zinc-clad steel lightning protection grounding wire

A lightning protection grounding, zinc-clad steel technology, applied in metal wire drawing, process efficiency improvement, manufacturing tools, etc. layer cracking or spalling and other problems, to achieve strong practicability and economic value, improve comprehensive utilization, and improve construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

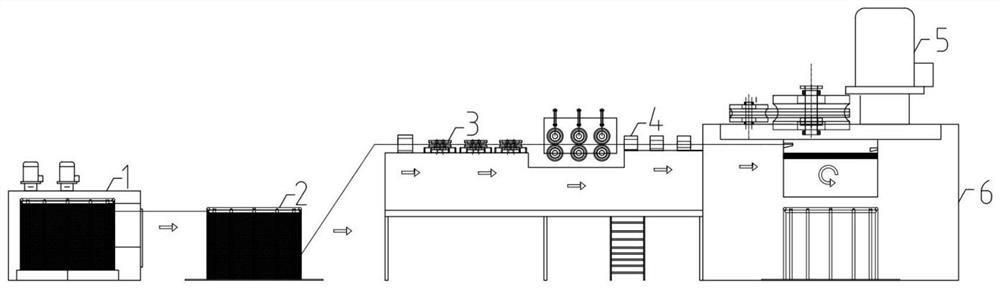

Image

Examples

Embodiment 1

[0029] The final finished product specification is φ16-a3 (that is, the total diameter is 16mm, the thickness of the zinc layer is 3mm, and the diameter of the steel core is 10mm).

[0030] Material requirements before processing: φ20.8mm-A3.9, the purpose is to control the cross-area change ratio of zinc-packaged steel products at 35-45 % by pulling the process. the goal of.

[0031] A multi-level pull method of bending flexible zinc-pack steel lightning protection ground line, including the following steps: select 100 meters φ20.8mm-A3.9, heat the product in the industrial return furnace for 30 minutes, heat thermal insulation for 10 minutes, temperature temperature Set to 300 ° C. After 40 minutes, remove the product from the back furnace and move it to the closing device (heated in the industrial oven, the main working principle is to prevent the product from appearing in the process of pulling up, preventing the product from appearing at straight when straight. Zinc layer bre...

Embodiment 2

[0036] The final finished product specification is φ14-a1 (that is, the total diameter is 14mm, the thickness of the zinc layer is 1mm, and the diameter of the steel core is 12mm).

[0037] Material requirements before processing: φ18.2mm-A1.3, the purpose is to control the cross-area change ratio of zinc-packaged steel products at 35-45 % by pulling the process. the goal of.

[0038]A multi-level pull method of bending flexible zinc bag steel lightning protection ground line, including the following steps: select 100 meters φ18.2mm-A1.3, heat the product in the industrial return furnace for 25 minutes, heat thermal insulation for 10 minutes, temperature temperature, temperature Set to 280 ° C. After 40 minutes, remove the product from the industrial oven and move it to the closing device (heated in the return furnace, the main working principle is to prevent the product from appearing in the process of pulling up, preventing the product from appearing in straight when straight. Z...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com