Full-automatic knife sharpener

A knife sharpener, fully automatic technology, applied in the direction of grinding drive device, grinding machine parts, grinding/polishing equipment, etc., can solve the problems of uneven grinding, edge fracture, inconvenience, etc. Knife works well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

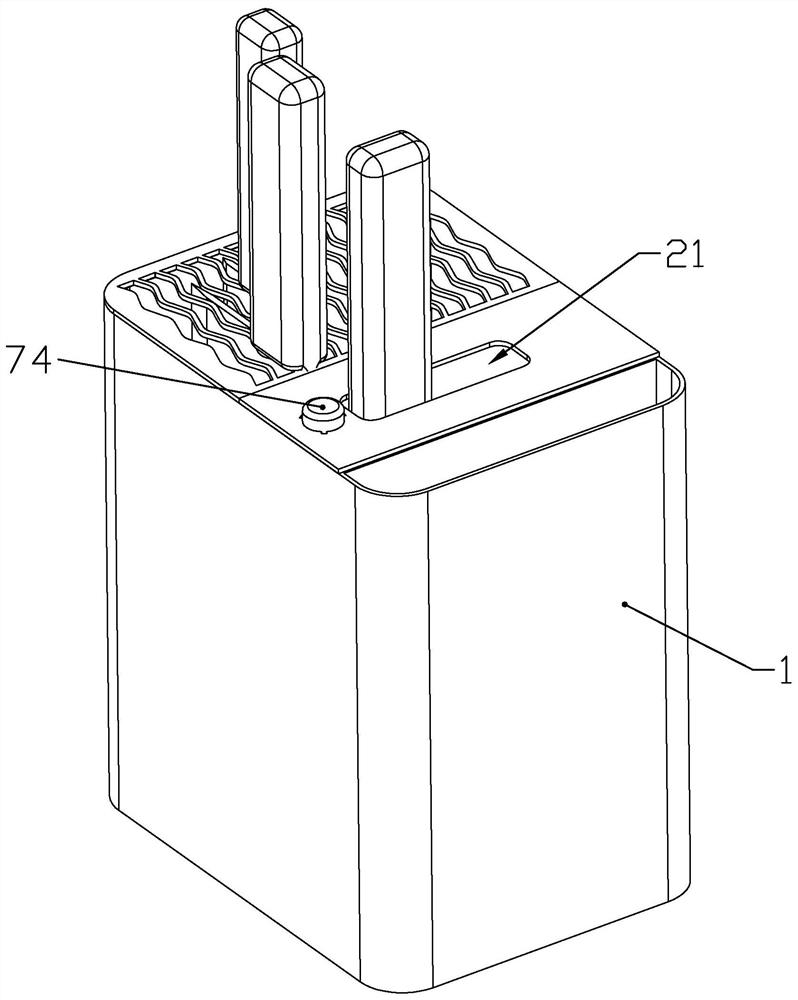

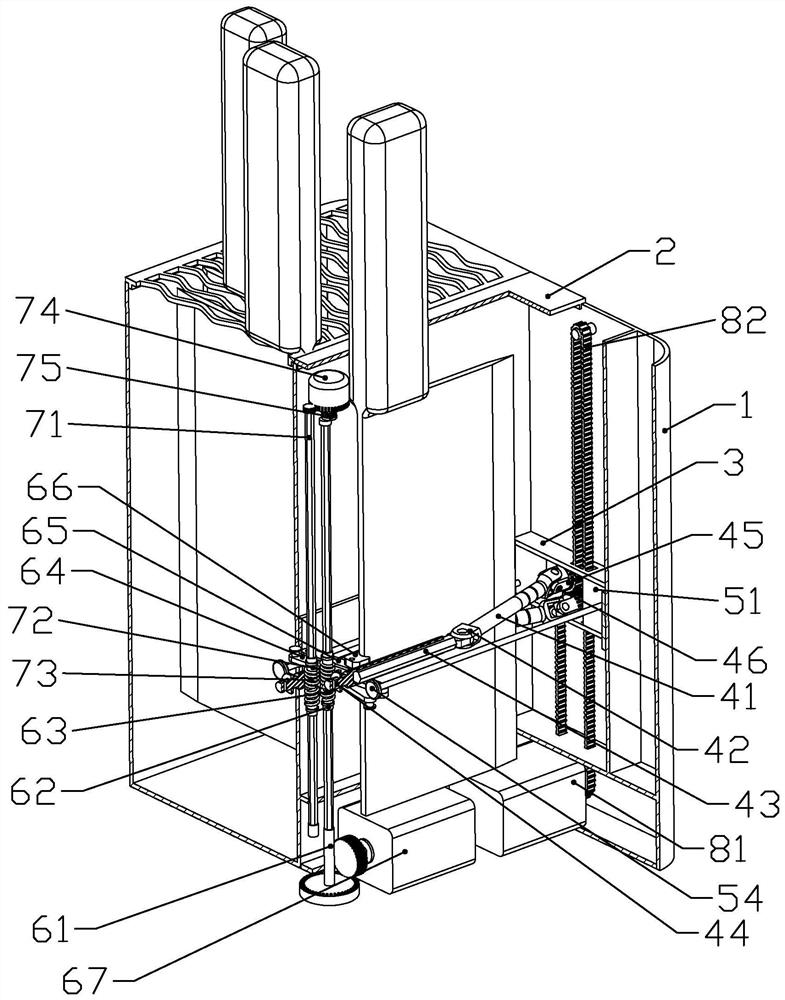

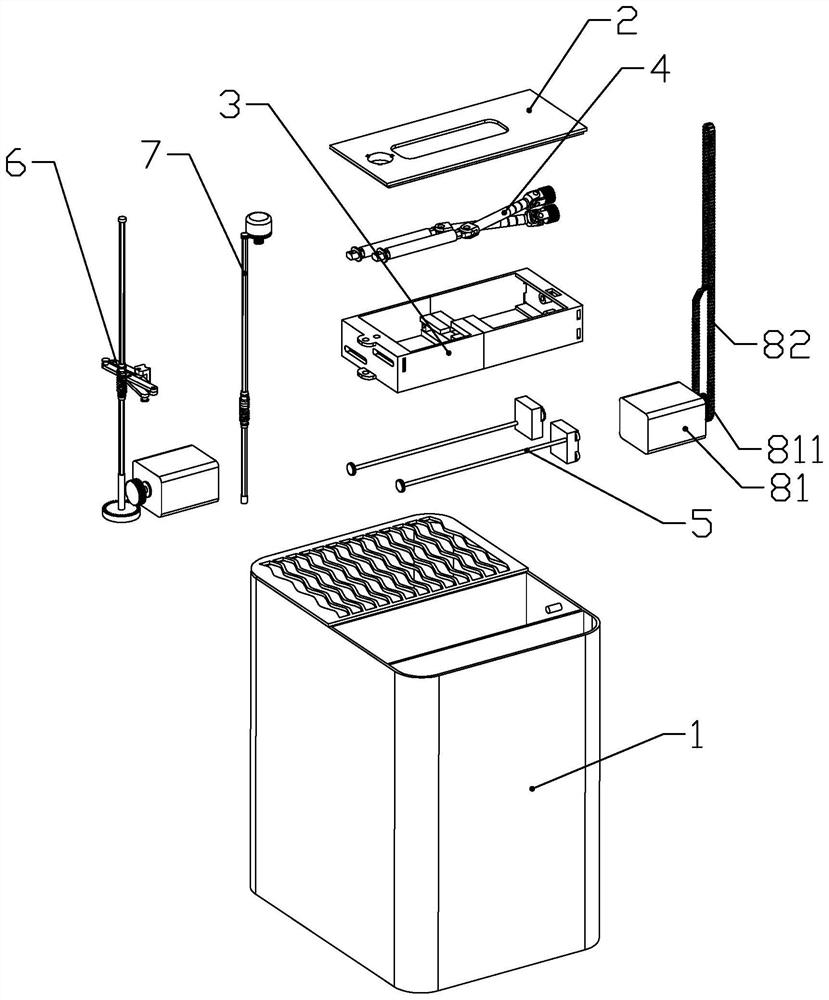

[0042] according to Figure 1 to Figure 13 As shown, a fully automatic knife sharpener described in this embodiment includes an outer casing 1 and a sliding frame 3 longitudinally slidably connected in the outer casing 1; two symmetrically arranged The knife sharpening assembly 4 used for sharpening the knife; the knife sharpening assembly 4 includes a sharpening pipe 41 that is rotatably connected to the rotating shaft in the sliding frame 3 and is horizontally arranged to be able to abut against the cutting edge and is rotatably connected to the The rotating shaft in the sliding frame 3 is horizontally arranged to drive the sharpening gear 45 for driving the sharpening tube 41 to rotate in the circumferential direction; the sharpening tubes 41 in the two sharpening assemblies 4 are arranged crosswise; the shell The body 1 is fixedly connected with a driving motor 81 for driving the sharpening gear 45 to rotate; the driving motor 81 is a stepping motor or a servo motor, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com