Feeding mechanism for preparing ultra-high molecular weight polyethylene mixture

An ultra-high molecular weight polyethylene technology, applied in the field of ultra-high molecular weight polyethylene preparation, can solve the problems of low actual temperature, long heating and melting time, affecting the efficiency of raw material mixing, etc., so as to improve the mixing effect and improve the mixing effect. , the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

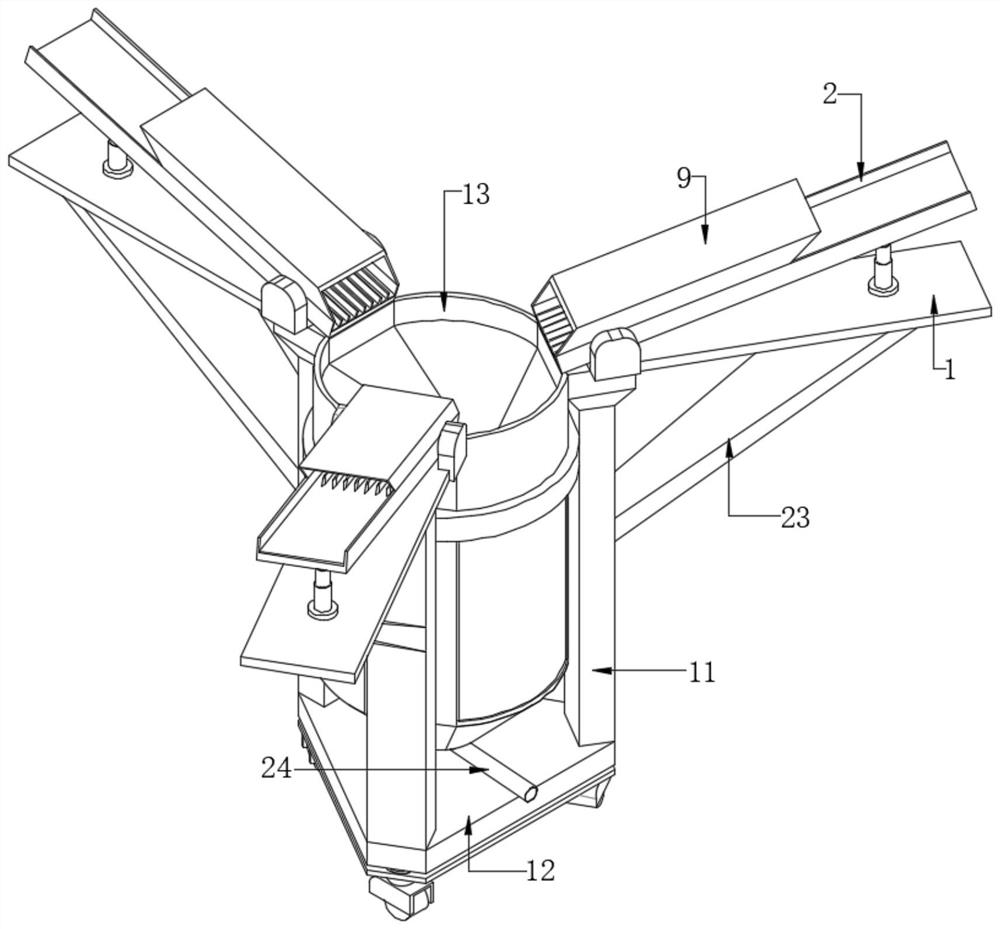

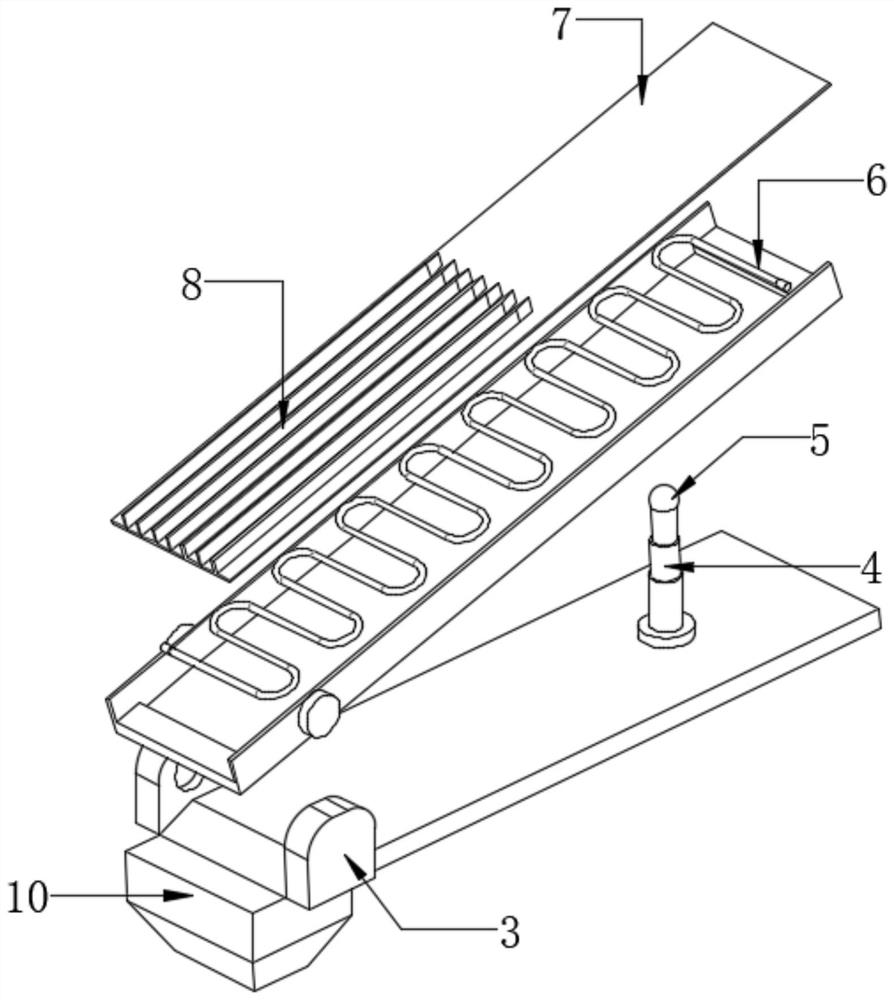

[0030] refer to Figure 1-4 , a feeding mechanism for preparing ultra-high molecular weight polyethylene mixture, including three platforms 1, the top of the three platforms 1 is provided with a feed box 2, and the outer walls on both sides of the platform 1 are connected with side seats 3 by bolts , the outer walls on both sides of the lower material box 2 are respectively connected with the inner walls of the side seats 3 on both sides through bearing rotation, the upper outer wall of the platform 1 is connected with a telescopic rod 4 through bolts, and the other end of the telescopic rod 4 is connected with a spherical seat through bolts 5, and the lower outer wall of the lower material box 2 is connected with a square seat by bolts, the spherical seat 5 is rotationally connected with the inner wall of the square seat, and the inner wall of one side of the lower material box 2 is provided with a groove, and the inner wall of the groove is connected by bolts There is a heat...

Embodiment 2

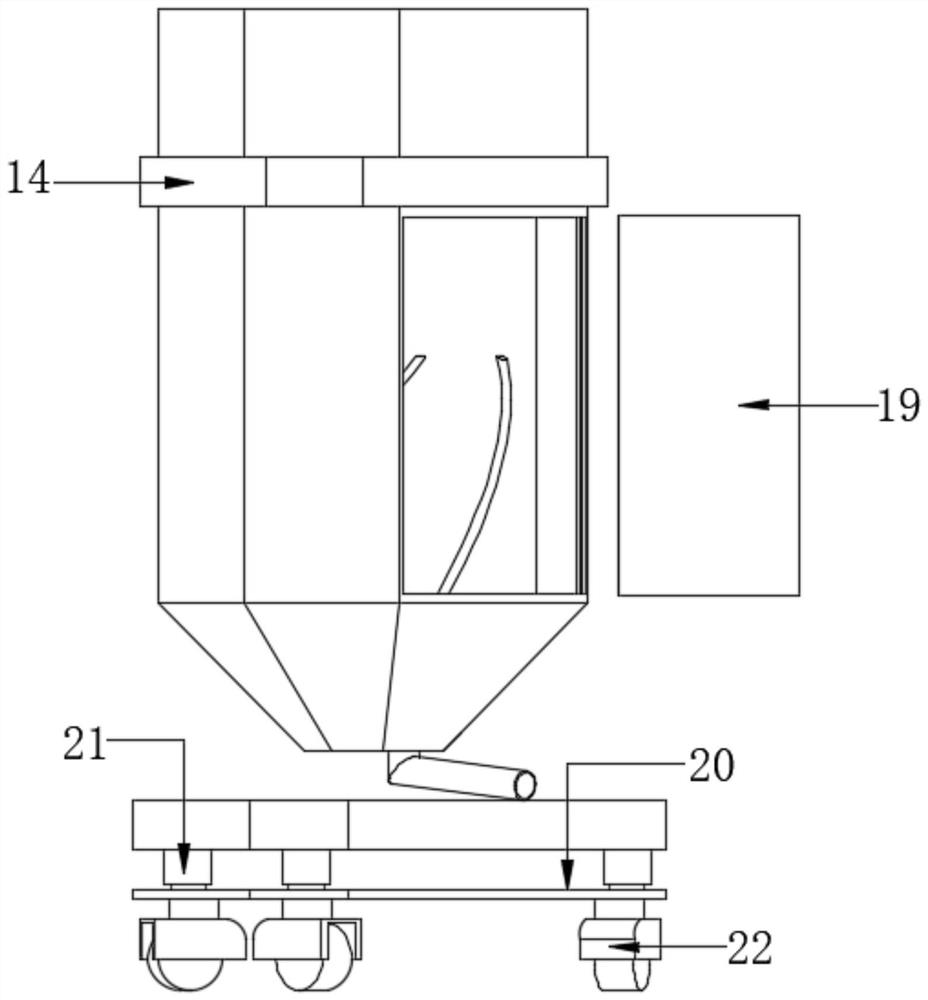

[0041] refer to Figure 5 , a feeding mechanism for preparing ultra-high molecular weight polyethylene mixture, including three platforms 1, the top of the three platforms 1 is provided with a feed box 2, and the outer walls on both sides of the platform 1 are connected with side seats 3 by bolts , the outer walls on both sides of the lower material box 2 are respectively connected with the inner walls of the side seats 3 on both sides through bearing rotation, the upper outer wall of the platform 1 is connected with a telescopic rod 4 by bolts, and the other end of the telescopic rod 4 is connected with a spherical seat by bolts 5, and the lower outer wall of the lower material box 2 is connected with a square seat by bolts, the spherical seat 5 is rotationally connected with the inner wall of the square seat, and the inner wall of one side of the lower material box 2 is provided with a groove, and the inner wall of the groove is connected by bolts There is a heating pipe 6, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com