Installation method of self-adjusting communication equipment

A technology of communication equipment and installation method, which is applied in the direction of mechanical equipment, building types, screws, etc., can solve problems such as loosening and dumping, communication base stations cannot withstand harsh environments, etc., and achieve the effect of avoiding loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

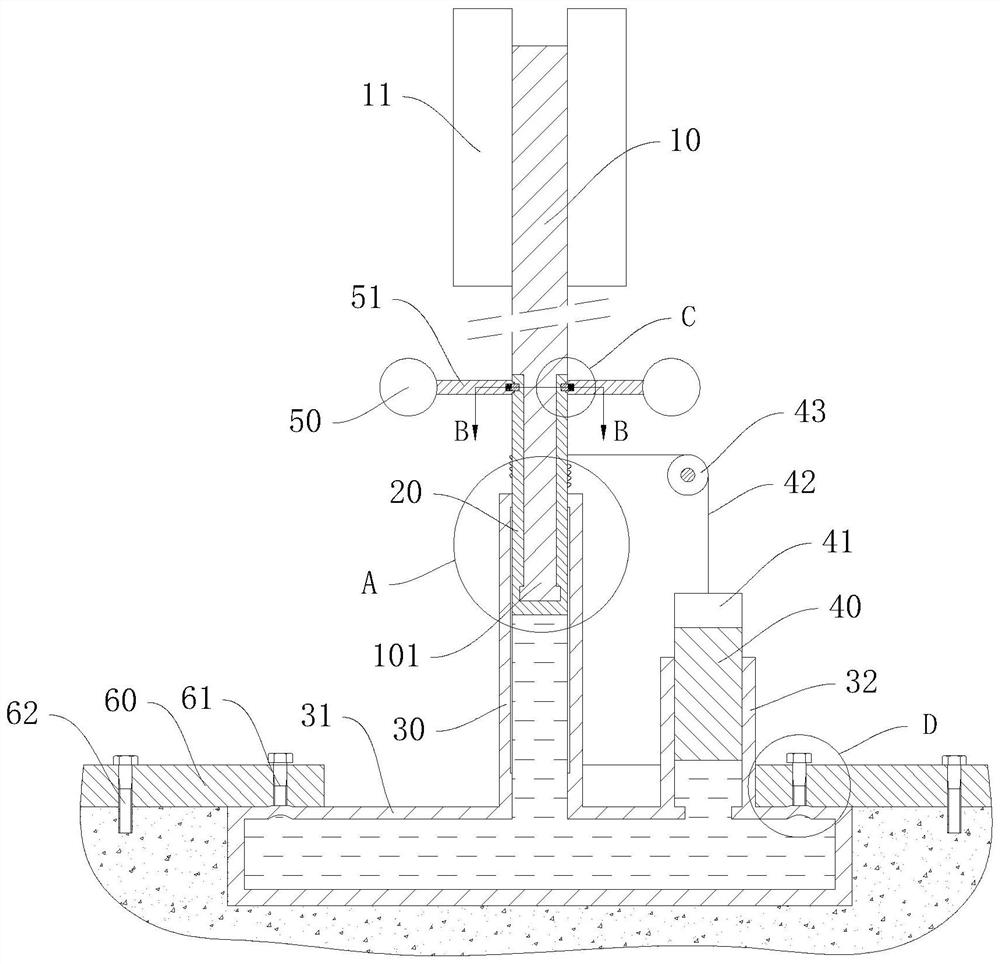

[0053] Such as Figure 1 to Figure 4 As shown, the embodiment of the present invention provides a self-adjusting communication device installation method, the communication device includes a transceiver device 11, and also includes:

[0054] The support device includes a base rod 10 and a support rod 101, the support rod 101 is coaxially fixed on the base rod 10, the support rod 101 is located below the base rod 10, and the transceiver device 11 is fixedly arranged on the base rod 10;

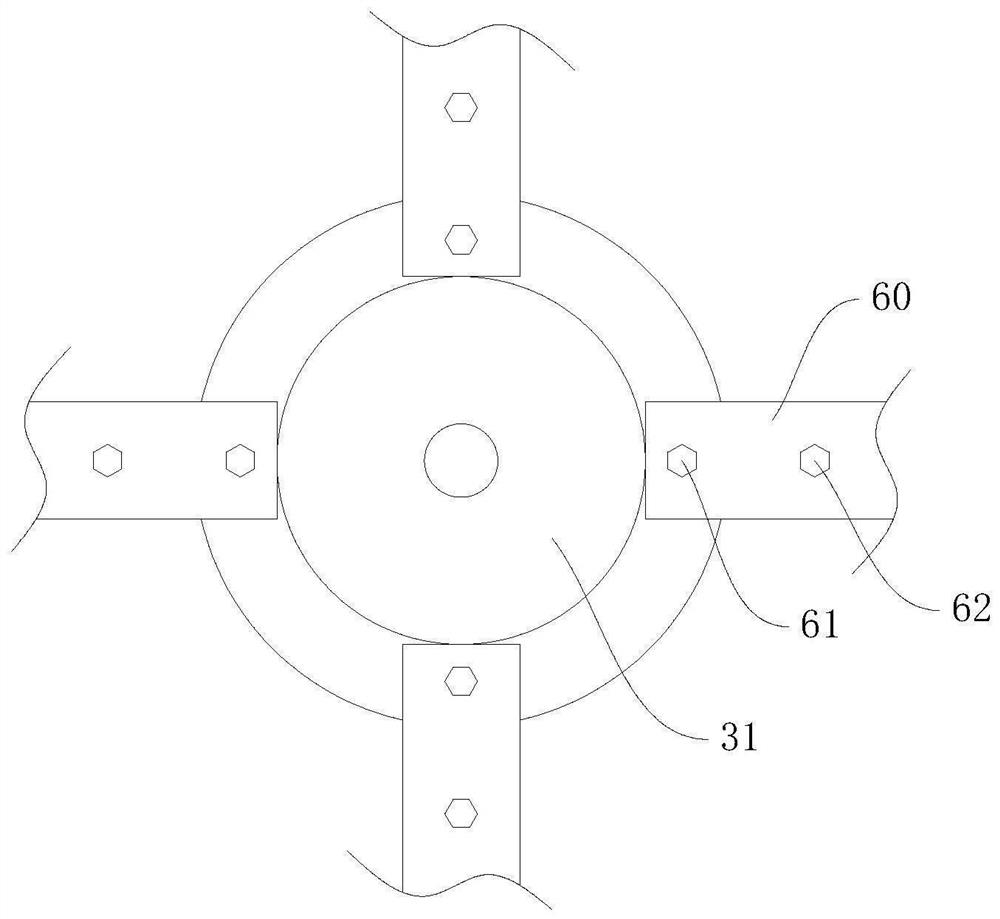

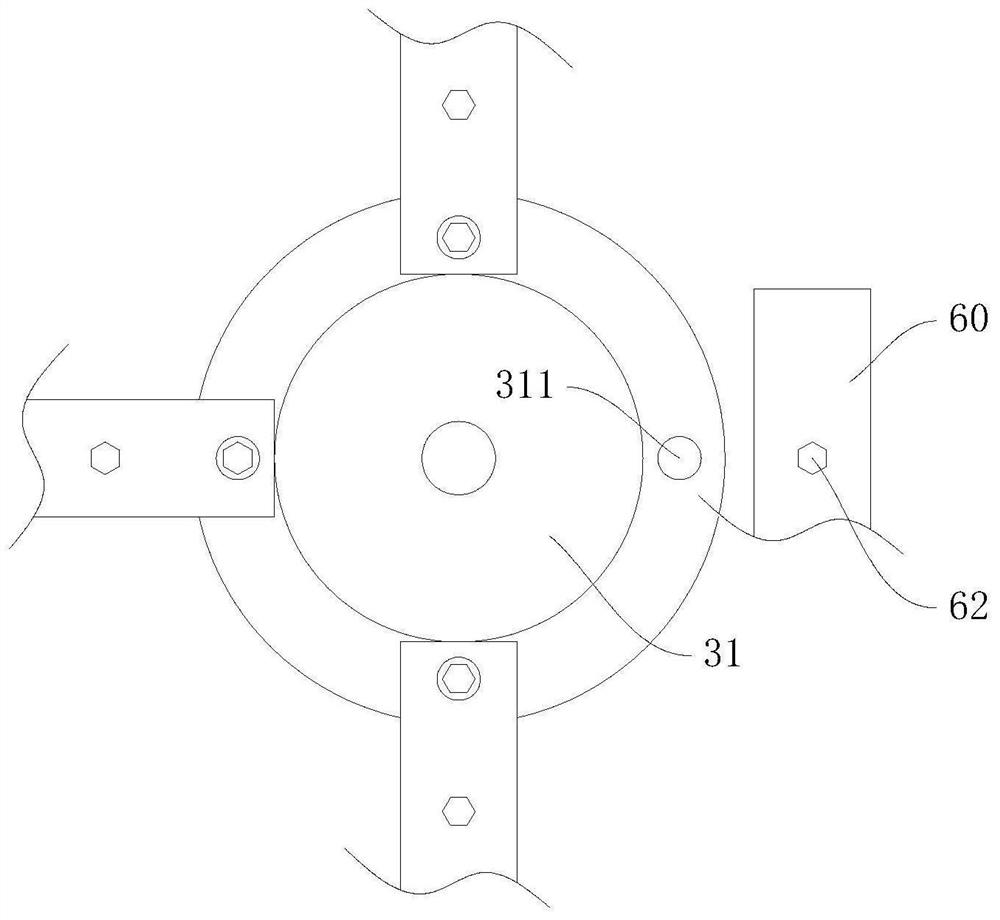

[0055] The fixing device comprises a longitudinal rod 30, a flange 31, a pressure plate 60, a compression bolt 61 and a fastening bolt 62, the longitudinal rod 30 is fixedly arranged on the flange 31, and the longitudinal rod 30 and the flange 31 are coaxially arranged , the longitudinal rod 30 and the flange 31 are both hollow structures, the longitudinal rod 30 penetrates into the flange 31, and the upper end of the longitudinal rod 30 is open; the support rod 101 is arranged in the longitudi...

Embodiment 2

[0067] In the first embodiment, due to the loosening of the bolts and / or the loss of hydraulic oil, the support rod 101 will move down, thereby causing the height of the transceiver device 11 to decrease, which does not meet the design requirements. Therefore, this embodiment also includes a weight 40, such as figure 1 As shown, the flange 31 is provided with an adjustment rod 32, the adjustment rod 32 is a hollow structure and penetrates into the flange 31, and the weight 40 is arranged in the adjustment rod 32 in a sealed and sliding manner up and down; the weight of the weight 40 is greater than The sum of the weights of the support rod 101 and the transceiver device 11 keeps the support rod 101 at the top. After the bolts are loosened and / or the hydraulic oil is lost, due to the heavy weight of the heavy hammer 40, the heavy hammer 40 is preferentially lowered to increase the pressure of the hydraulic oil, so that the pressing bolt 61 and the fastening bolt 62 are pressed t...

Embodiment 3

[0070] On the basis of embodiment one or two, such as Figure 6 As shown, since the communication base station is set high on the roof of the building, when the wind is strong, it is easy to cause excessive load on the base pole 10, resulting in equipment damage, fatigue of the installation structure, etc., and even the breakage of the base pole 10 affects communication. The embodiment also includes a rotating sleeve 20, a connecting rod 51, a wind cup 50, and a cable 42. The support rod 101 is rotatably arranged in the rotating sleeve 20. The lower end of the rotating sleeve 20 is closed and is dynamically and sealedly connected with the longitudinal rod 30. Because the transceiver device 11 and the base rod 10 have weight, and when the rotating sleeve 20 rotates, the support rod 101 remains relatively stationary to a certain extent; the rotating sleeve 20 is provided with an external thread, and the longitudinal rod 30 is provided with an internal thread matched with the exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com