Buffering and damping part

A technology of parts and spirals, applied in the field of buffering and shock absorption devices, can solve the problems of shortening the service life, easy damage of the composite foam layer, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

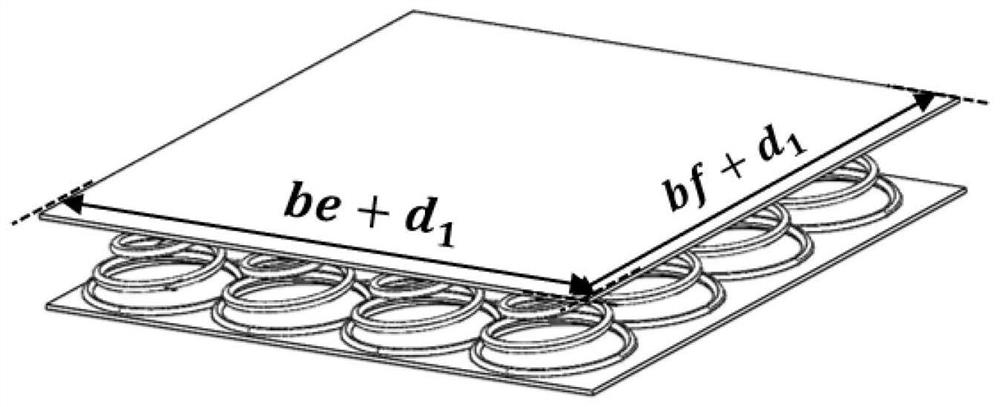

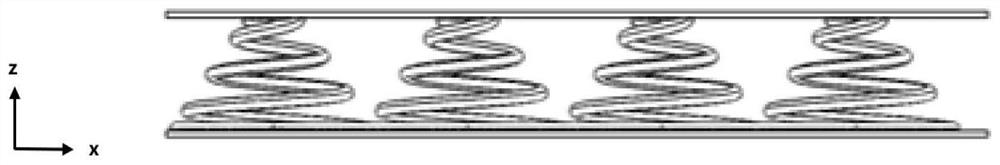

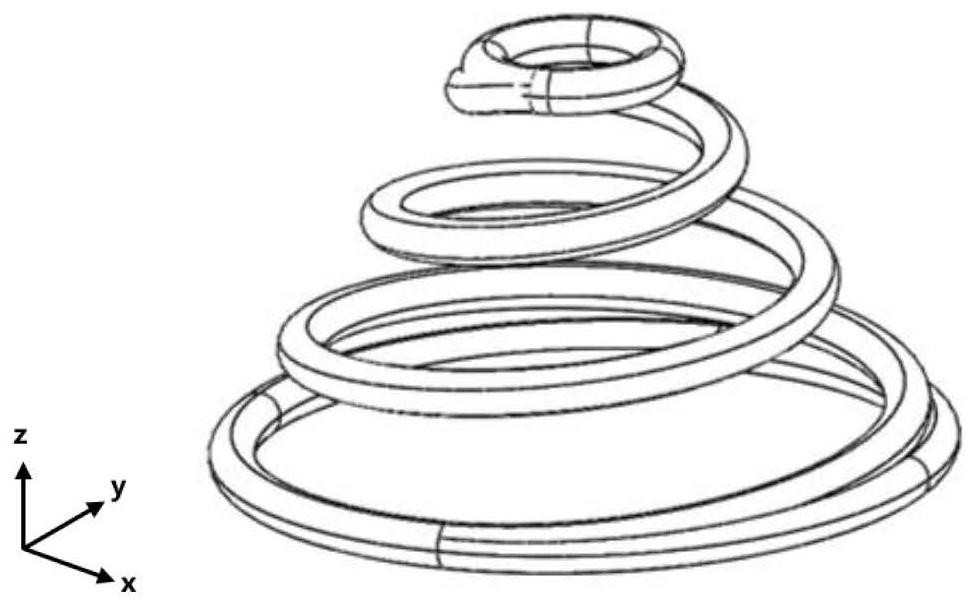

[0044] For lattice springs, the array dimensions in the x and y axis directions are both b=480mm, and the numbers of hollow springs in the x and y axis directions are 4 and 4 respectively; the first solid helical spring, d 1 = 30mm, a 1 = 60mm, n 1 = 3, D 1 =480mm; the second solid coil spring, n 2 = 3, D 2 = 480mm, a 2 =60mm, d 2 = 20mm, h 2 =90mm; the length and width of the bearing plate are 1950mm and 1950mm respectively, and the height is 15mm.

[0045] When forming the cushioning and shock absorbing part, first convert the modeling file into an stl format file and import it into the slicing software, add Ti-6Al-4V powder into the powder box, and use the powder spreading device to spread the powder in the forming cylinder. Laser scanning is melted and solidified, and the lifting table is lowered by 0.03mm. Repeat the above steps until the printing of the lower carrier plate is completed; replace Ti-6Al-4V in the powder box with Ni-Ti shape memory alloy powder, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com