Bevel gear forge piece tooth thickness online detection tool

A technology for bevel gears and forgings, which is applied in the field of on-line testing tools for tooth thickness of bevel gear forgings, which can solve the problems of increasing the cost of use, reducing the practicability of testing tools, and not being suitable for large-scale testing, so as to facilitate operators and improve practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

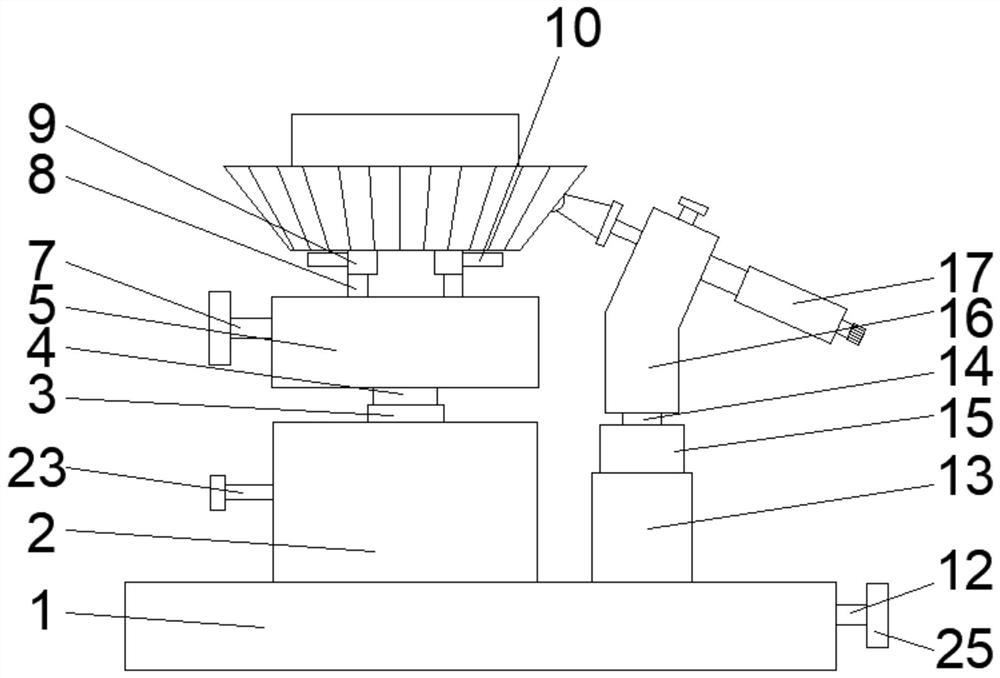

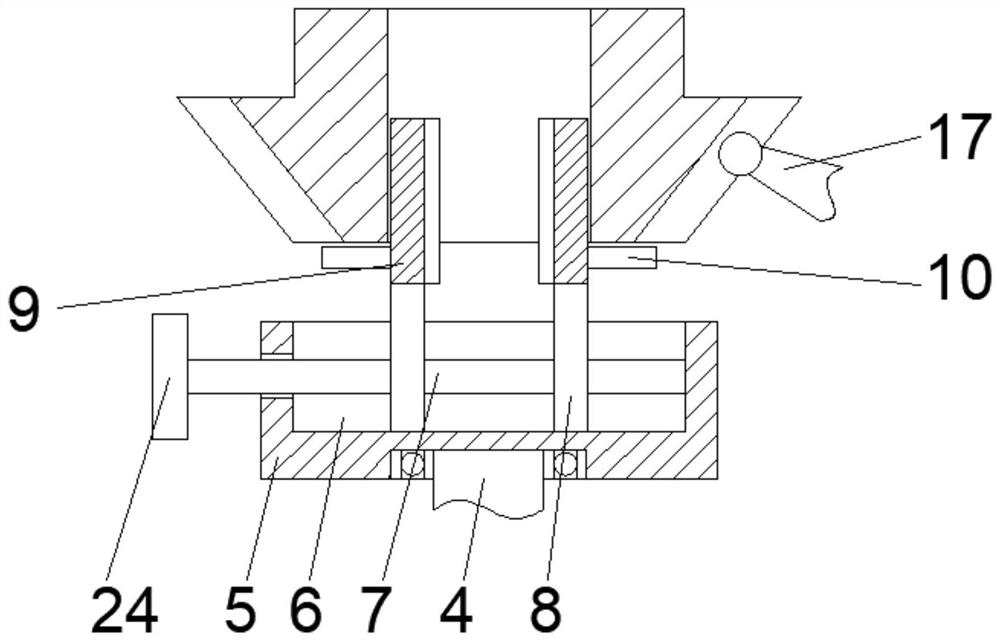

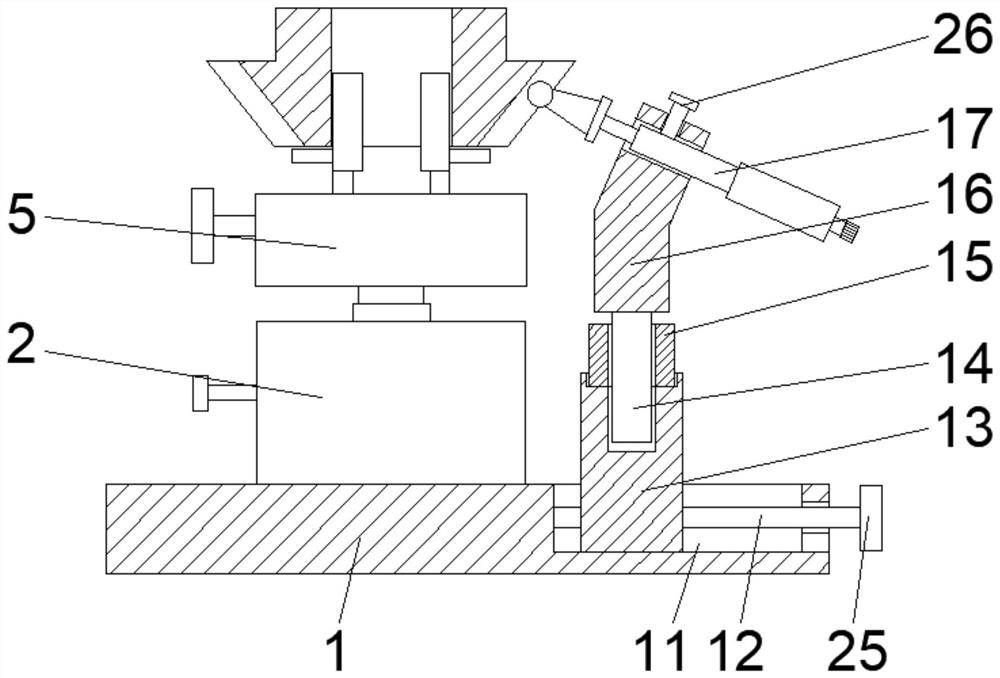

[0027] like Figure 1-4 As shown, the embodiment of the present invention provides a bevel gear forging tooth thickness online inspection tool, including a base plate 1, the upper surface of the base plate 1 is fixedly connected with a base 2, the upper surface of the base 2 is slidably connected with a support rod 3, and the support rod 3 is fixedly connected to the top end of the rotating shaft 4, the outer surface of the top end of the rotating shaft 4 is sheathed and rotatably connected to a support plate 5, the upper surface of the support plate 5 is provided with a first chute 6, and the inside of the first chute 6 is rotatably connected to a second chute. A threaded rod 7, the first threaded rod 7 is located in the first chute 6 inner one end outer surface is symmetrically sleeved with a connecting rod 8 connected by thread rotation, the tops of the two connecting rods 8 are fixedly connected with splints 9, two The side of the outer surface of the splint 9 that is rela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com