Welding spot positioning method and system based on image processing

A positioning method and image processing technology, applied in image data processing, image analysis, image enhancement, etc., can solve problems such as loss, time-consuming, and error-prone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be described in further detail below in conjunction with the examples, but the implementation of the present invention is not limited thereto.

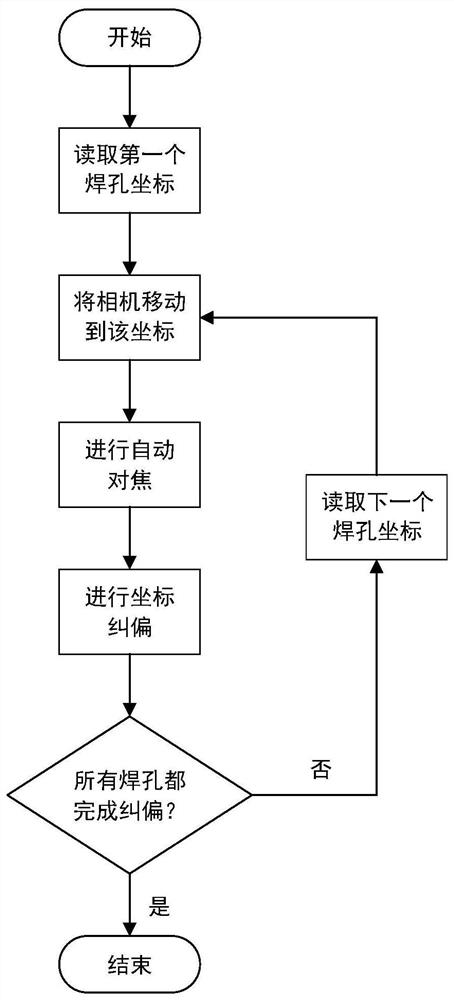

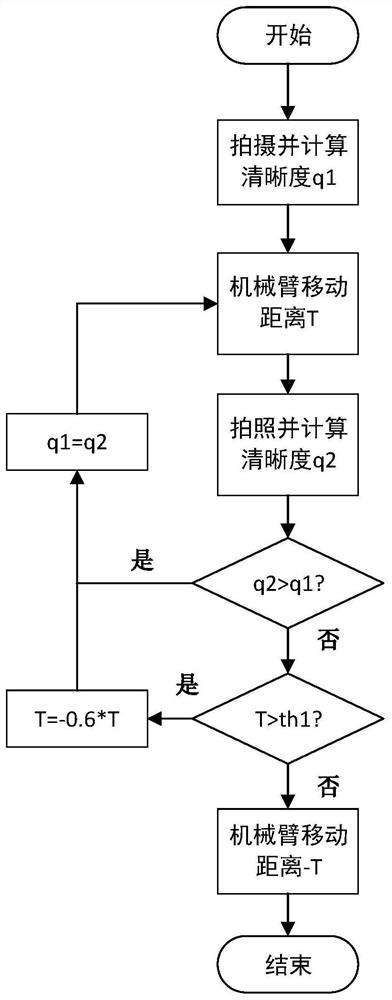

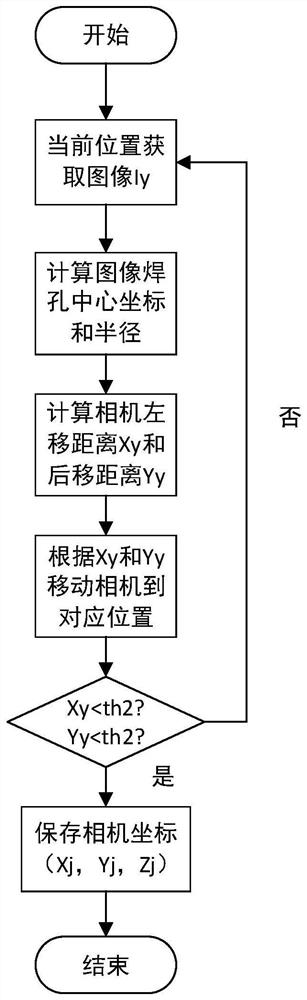

[0065] The principle of the present invention is to move a mechanical arm equipped with an industrial camera and connected to a computer to a coordinate of a welding point through the obtained assembly design dimensions, that is, the position coordinates of the welding points on the assembly drawing, and take an image of the workpiece at this position After the auto-focus operation, after obtaining a clear image of the workpiece, calculate the center position coordinates of the solder joint workpiece, and replace the calculated coordinate value with the design coordinate value of the point, that is, complete the positioning of the solder joint position coordinates. The mechanical arm moves to the design coordinates of the next welding point, and repeats the above operations and calculations until the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com