Insulated high-voltage power cable

A high-voltage power and cable technology, which is applied in the direction of power cables, insulated cables, and power cables with shielding layers/conductive layers, etc., can solve problems such as easy scratches on the outer protective sleeve, poor protection effect, difficult maintenance and replacement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

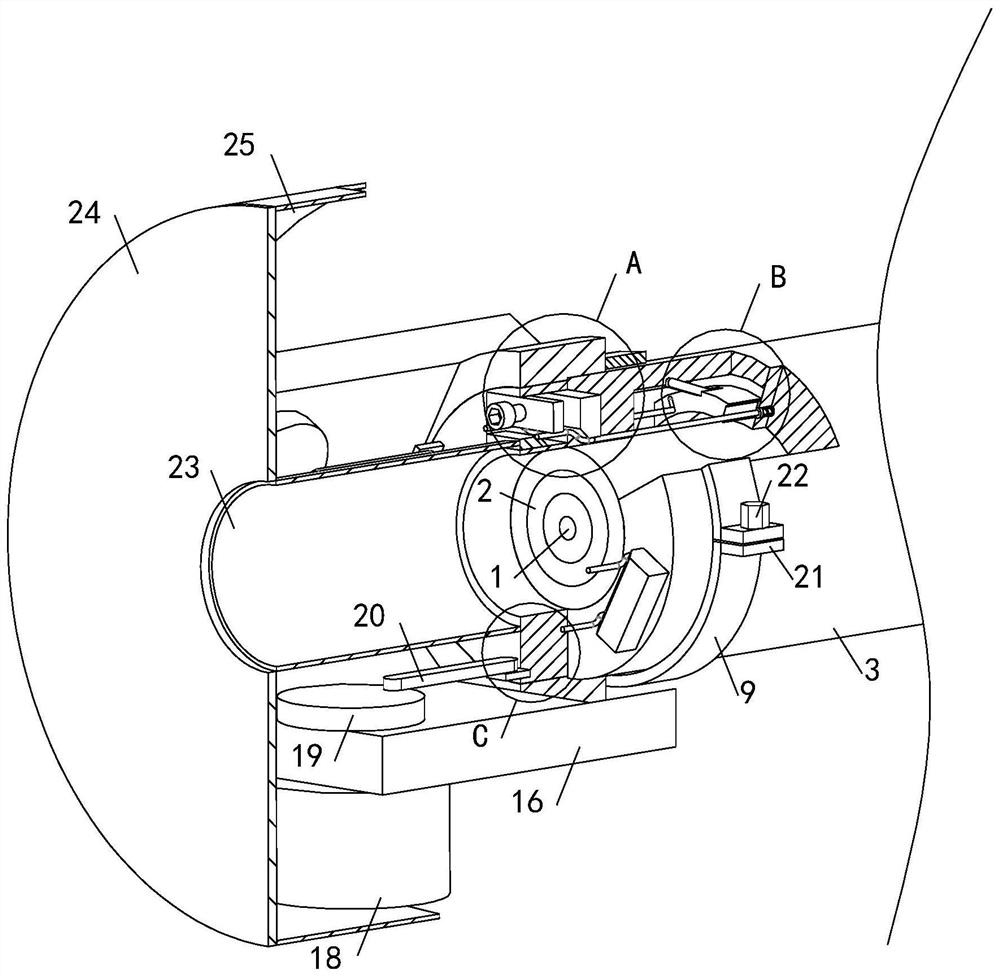

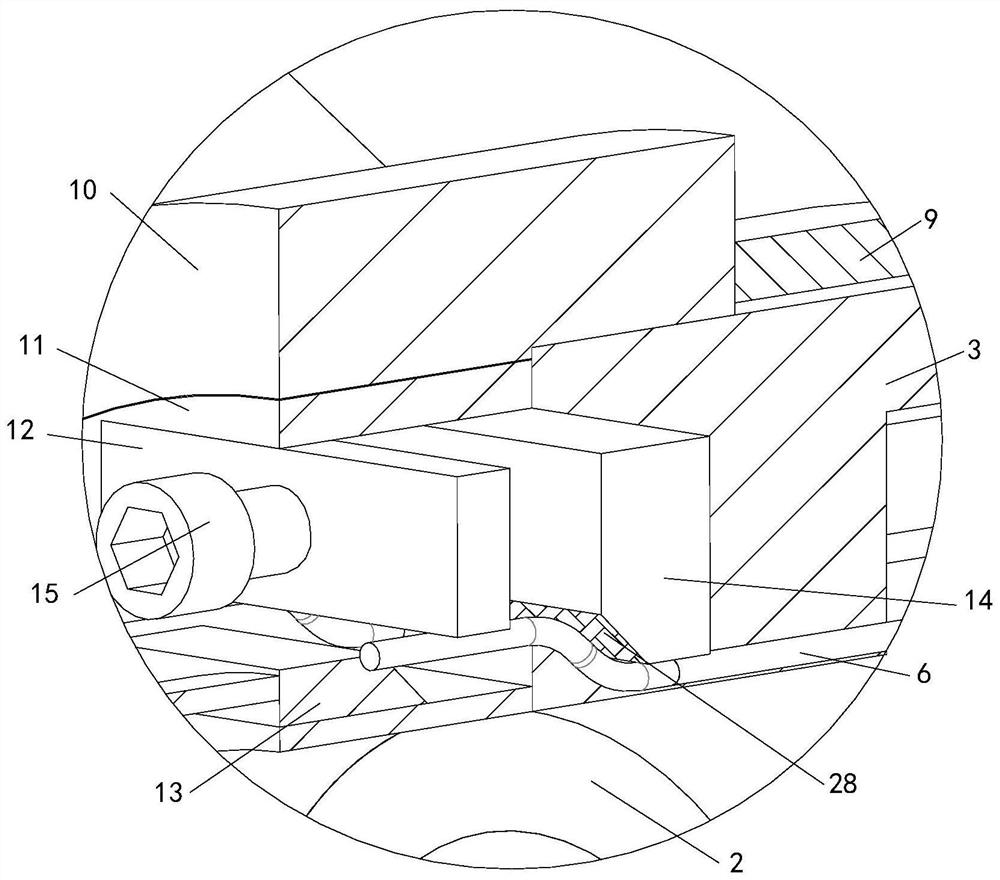

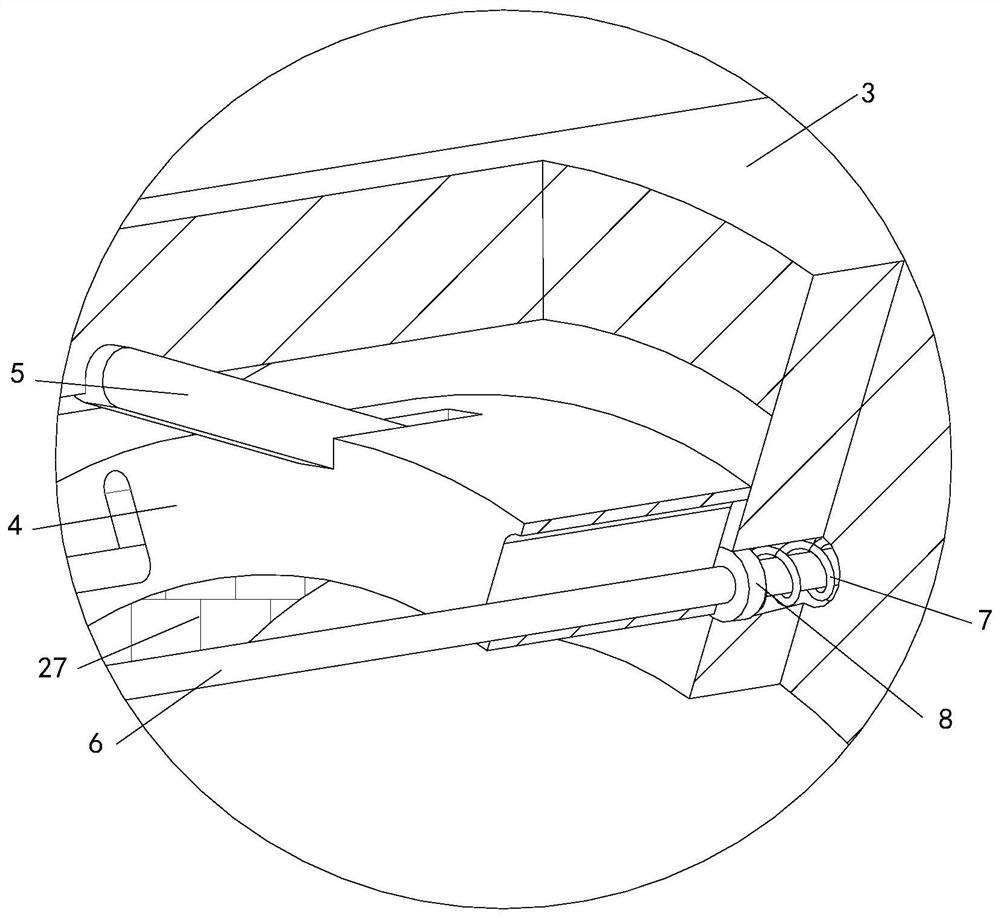

[0031]SeeFigure 1-5An insulating high voltage power cable includes a cable conductor 1, further comprising a protective multilayer sleeve 2, and the cable conductor 1 is disposed in the protective multi-layer sleeve 2, and the external set of protective multi-layer sleeves 2 has a shielded insulating tube 3, which is convenient for insulation. The protection of the protective multi-layered 2 is not easily damaged during the laving process of high voltage power cable, and the protection is better, and the protective multi-layer set 2 is better, and there are many in the shield insulation tube 3. The loop group, the ring groove group includes three mounting grooves, and there is a curved block 4 in three mounting grooves, and the rotary push rod 5 is connected between the curved block 4 and the mounting slot, which is easy to move relative to the shield insulating tube 3. The protective multi-layer sleeve 2 and the cable conductor 1 are easily repaired after the cable conductor 1 is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com