Method for preparing circuit board and circuit board

A circuit board and breathable board technology, which is applied in the direction of printed circuit manufacturing, printed circuit, printed circuit, etc., can solve the problems of circuit board deformation, plug hole is not full, plug hole empty, etc., to ensure smoothness, plug hole full, plugged Hole leveling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

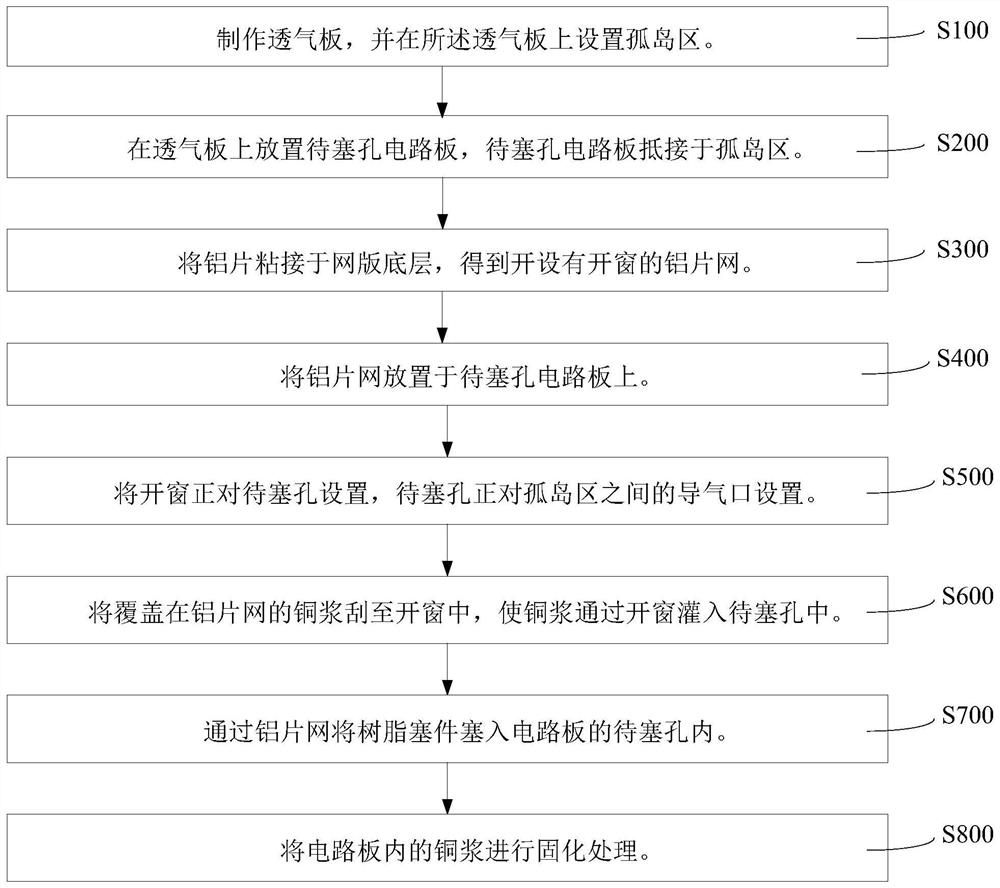

[0034] The present application provides a method for preparing a circuit board. The method for preparing a circuit board includes the following steps: making a ventilating board, and setting an island area on the ventilating board; placing a circuit board to be plugged on the ventilating board; The circuit board to be plugged is in contact with the island area; the aluminum sheet is bonded to the bottom layer of the screen to obtain an aluminum sheet mesh with windows; the aluminum sheet mesh is placed on the circuit board to be plugged ; Set the opening to the hole to be plugged, and the hole to be plugged is set to the air guide between the island areas; scrape the copper paste covered on the aluminum mesh to the opening , pour the copper paste into the hole to be plugged through the window; plug the resin plug into the hole to be plugged on the circuit board through the aluminum mesh; put the copper paste in the circuit board Carry out curing treatment.

[0035] The above-...

Embodiment 1

[0094] Select a ventilation board with a thickness of 2.0mm, and the length of the ventilation board is 30mm larger than that of the circuit board to be plugged, and the width of the ventilation board is 30mm larger than that of the circuit board to be plugged. Carry out controlled depth drilling operation on the ventilating plate to obtain an island area on the ventilating plate. Place the circuit board to be plugged on the ventilation plate so that the circuit board to be plugged abuts against the island area. The aluminum sheet is bonded to the bottom layer of the screen to obtain an aluminum sheet mesh with windows, and then the aluminum sheet mesh is placed on the circuit board to be plugged. Set the opening window facing the hole to be plugged, and set the plug hole facing the air guide between the island areas. Scrape the copper paste covered with the aluminum mesh into the opening window, so that the copper paste is poured into the hole to be plugged through the openin...

Embodiment 2

[0096] Select a ventilation board with a thickness of 2.5mm, and the length of the ventilation board is 50mm larger than that of the circuit board to be plugged, and the width of the ventilation board is 50mm larger than that of the circuit board to be plugged. Carry out controlled depth drilling operation on the ventilating plate to obtain an island area on the ventilating plate. Place the circuit board to be plugged on the ventilation plate so that the circuit board to be plugged abuts against the island area. The aluminum sheet is bonded to the bottom layer of the screen to obtain an aluminum sheet mesh with windows, and then the aluminum sheet mesh is placed on the circuit board to be plugged. Set the opening window facing the hole to be plugged, and set the plug hole facing the air guide between the island areas. Scrape the copper paste covered with the aluminum mesh into the opening window, so that the copper paste is poured into the hole to be plugged through the openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com