Motor vehicle transmission for a hybrid drive train, and hybrid drive train

A motor vehicle transmission and hybrid technology, which is applied in the direction of hybrid vehicles, multi-ratio transmissions, and the arrangement of multiple different prime movers of general-purpose power plants, and can solve limited electrification, limited installation space, low drive/ Problems such as driving power, to achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

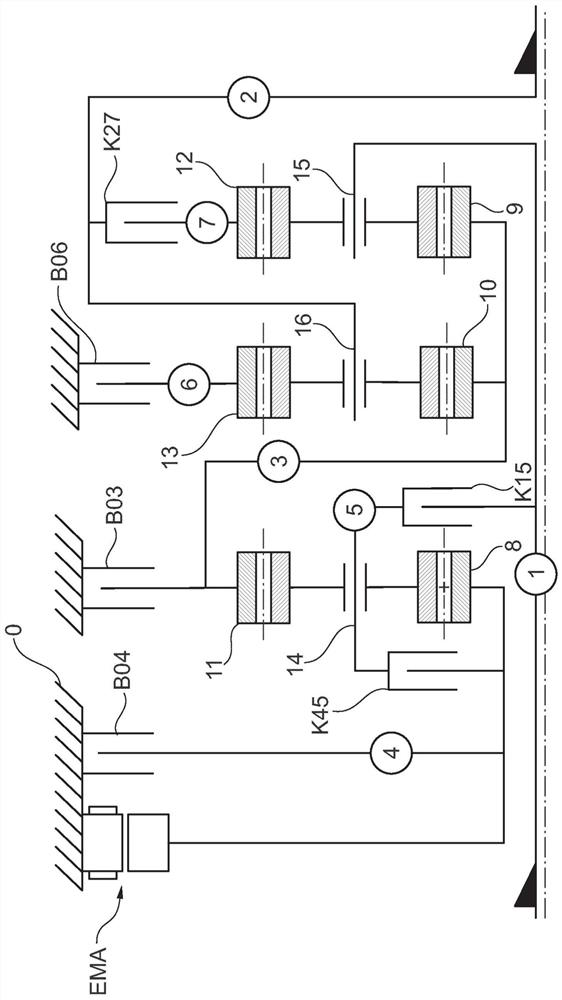

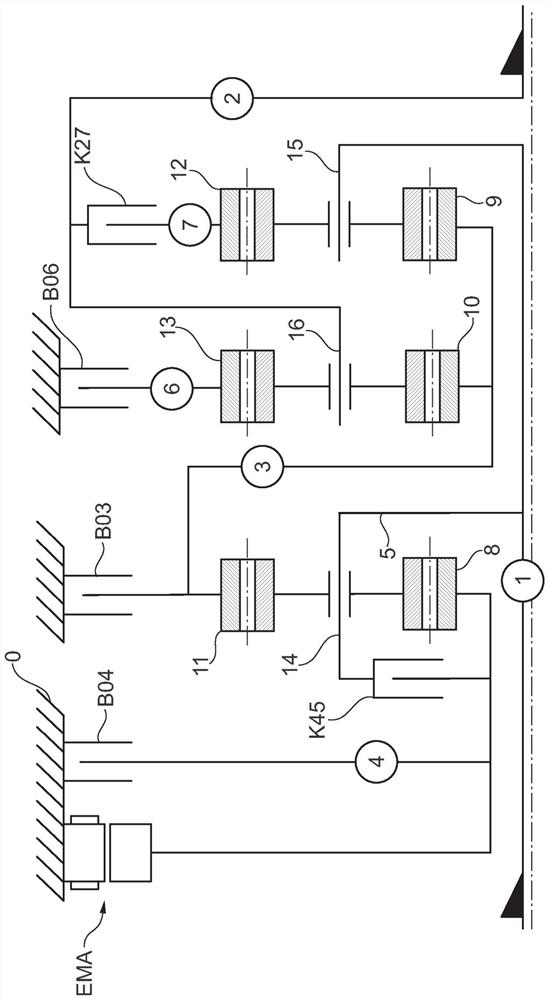

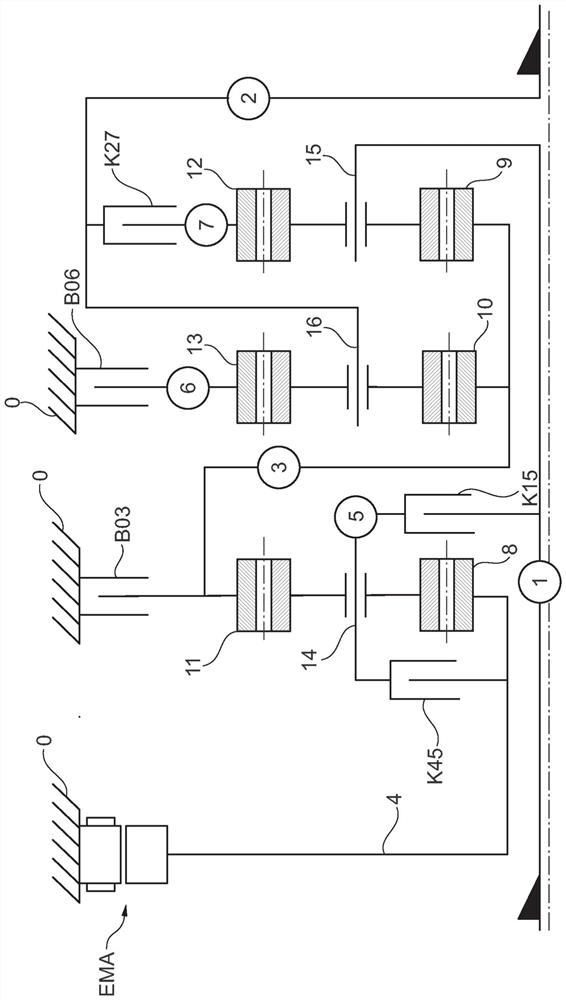

[0049] figure 1 The illustrated embodiment of the motor vehicle transmission has six shiftable forward gears and is a preferred embodiment of a motor vehicle with electric all-wheel drive.

[0050] An internal combustion engine is coupleable to a first transmission input shaft 1 (not shown). The second drive machine EMA is non-rotatably connected to the first sun pinion 8 via the first sun pinion shaft 4 . The first sun pinion 8 is selectively non-rotatably connected to the transmission housing 0 by means of the first sun pinion shaft 4 and the second brake B04 . First planet gears are rotatably mounted on the first planet carrier 14 , which mesh both with the first sun pinion 8 and with the first ring gear 11 for power transmission. The first ring gear 11 is non-rotatably connected to the third sun pinion 10 and the second sun pinion 9, and via the first ring gear shaft 3, the first ring gear can also be selectively connected to the transmission by means of the first brake ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com