Tea leaf fixation device and method

A greening device and tea technology, applied in the direction of tea treatment before extraction, etc., can solve the problems of affecting the quality of tea leaves, poor greening effect, uneven heating of tea leaves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

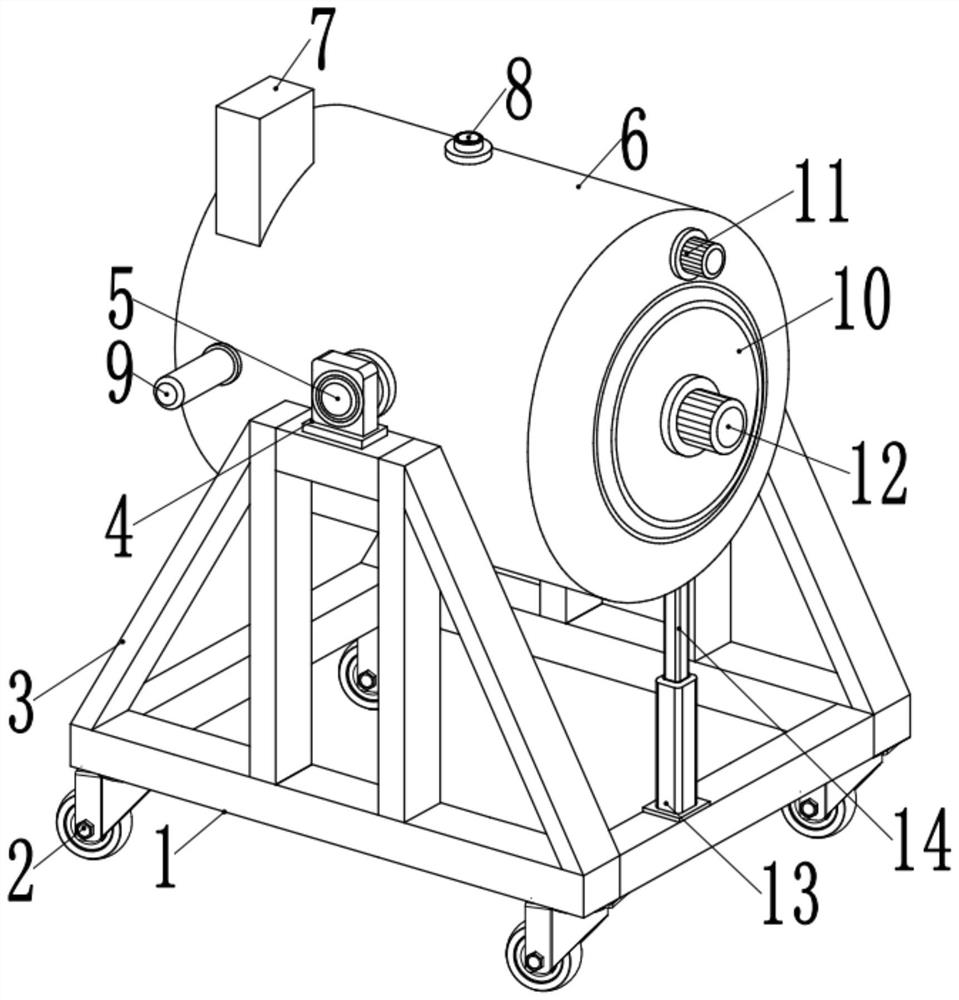

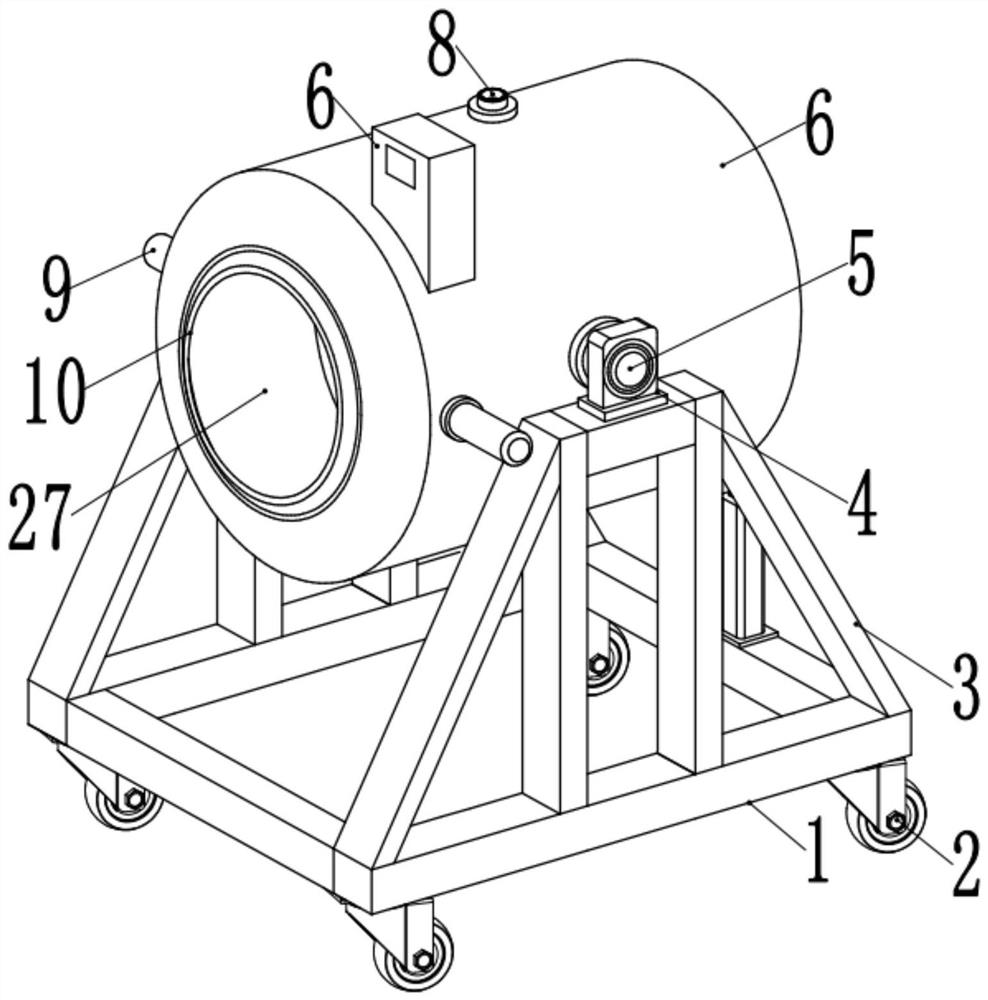

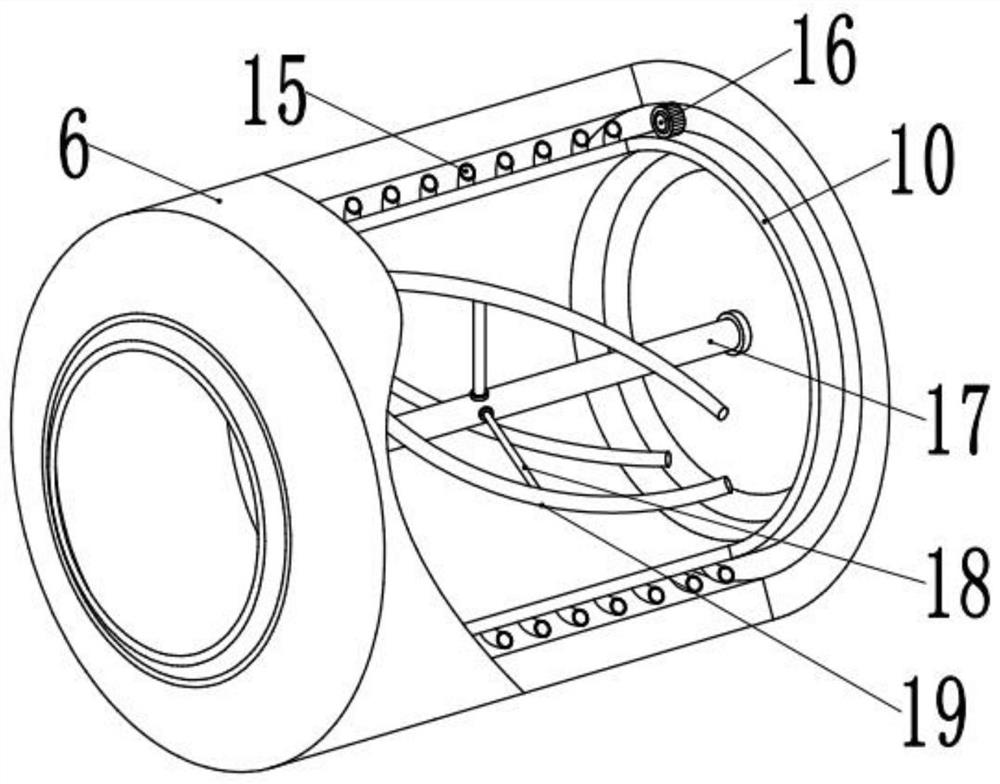

[0051] A tea greening device, comprising a base 1, an outer cylinder 6 and an inner cylinder 10, the inner cylinder 10 is movably connected to the inside of the outer cylinder 6, and the outer walls of both ends of the inner cylinder 10 are welded with convex edges 23, and the outer walls of the convex edges 23 are There is a wheel groove 24 at the center, and an outer cylinder ring 25 is welded on the inner side wall of the outer cylinder 6 close to the convex edge 23, and the inner side wall of the outer cylinder ring 25 is movably connected with positioning wheels 26 equidistantly distributed in a ring structure through a rotating shaft. , and the positioning wheel 26 is slidably connected to the inside of the wheel groove 24, and one end of the inner cylinder 10 is provided with a material opening 27, and the shaft center of the outer wall of the other end of the inner cylinder 10 away from the material opening 27 is installed with a second motor 12 through a bolt, the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com