Automatic cleaning equipment for automobile semi-filter

A filter and automatic technology, applied in the direction of filter regeneration, filtration separation, chemical instruments and methods, etc., can solve the problems of waste of cleaning liquid, cumbersome manual wiping of water stains, poor control of the amount of cleaning liquid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

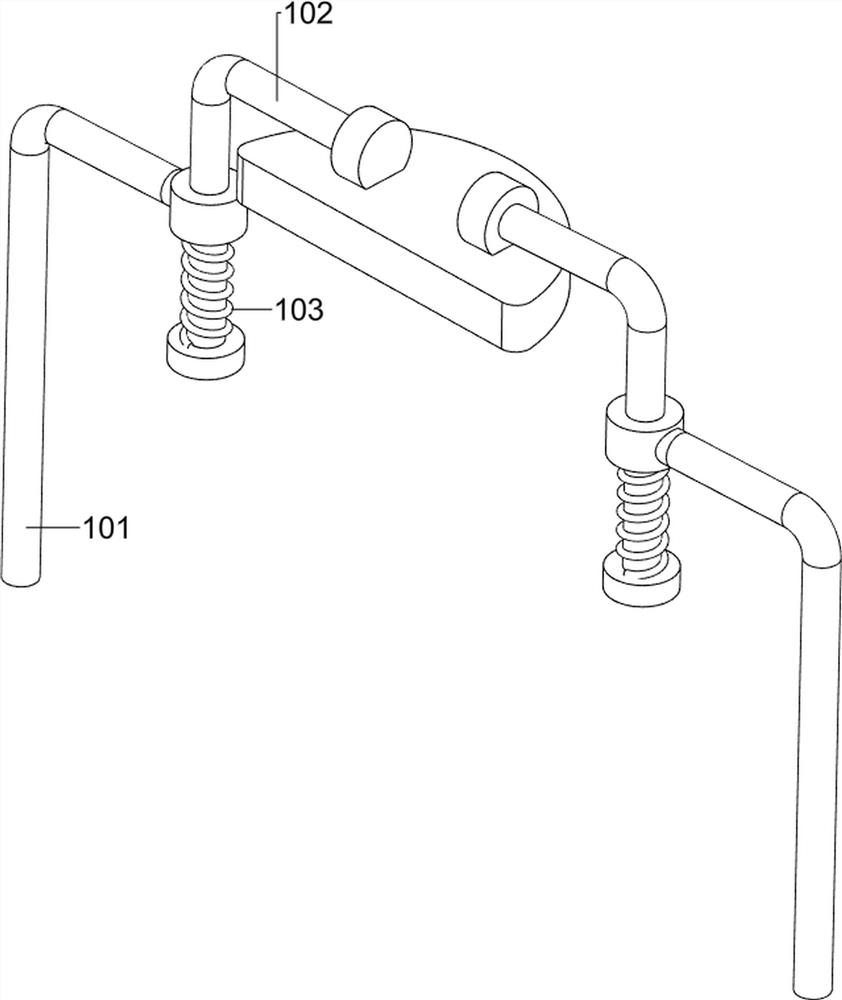

[0061] A kind of automatic cleaning equipment for automobile semi-filter, such as figure 1As shown, it includes a first support plate 1, a first support frame 2, a liquid tank 3, a liquid outlet pipe 4, a placement and rotation mechanism 5, a sending mechanism 6, a closing mechanism 7 and a quantitative liquid clamping mechanism 8, the first support The upper part of the rear side of the plate 1 is provided with a first support frame 2, the upper part of the first support frame 2 is provided with a liquid tank 3, the bottom of the liquid tank 3 is evenly provided with a liquid outlet pipe 4, and the first support plate 1 is provided with a placement rotation mechanism 5, Place the rotating mechanism 5 to be provided with a delivery mechanism 6, the liquid tank 3 to be provided with a closing mechanism 7, and the liquid tank 3 to be provided with a quantitative liquid clamping mechanism 8, which is in contact with the delivery mechanism 6 with the quantitative liquid clamping me...

Embodiment 2

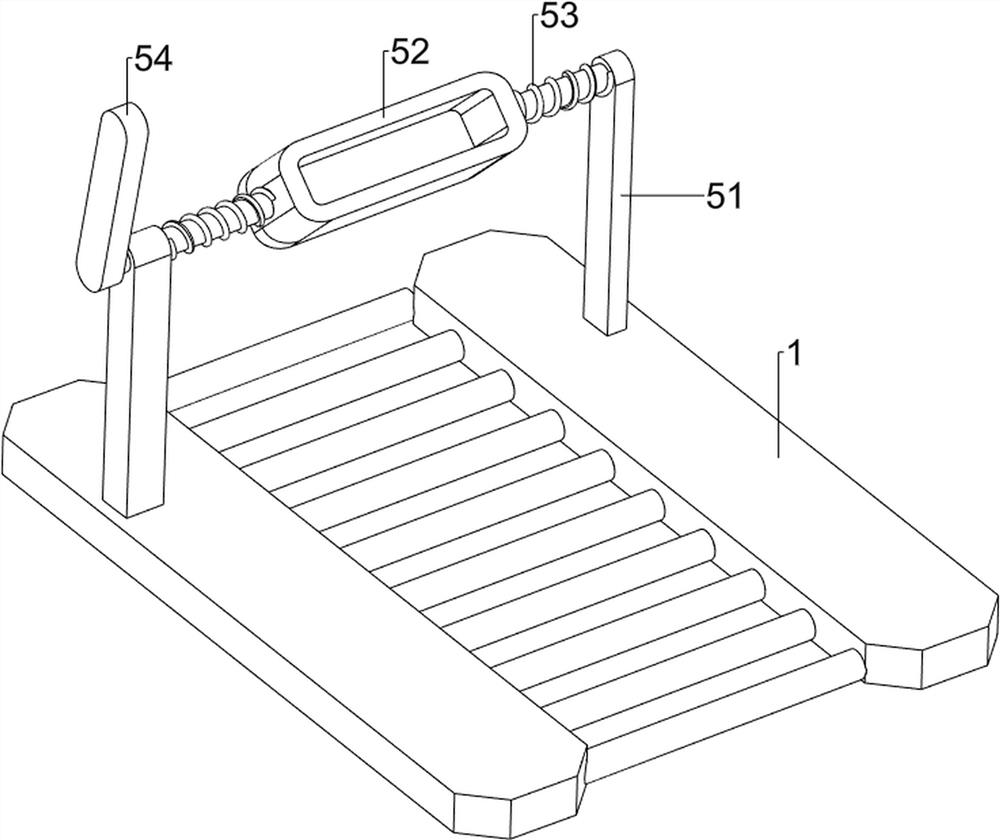

[0064] In a preferred embodiment of the present invention, as Figure 1-Figure 5 As shown, the placement and rotation mechanism 5 includes a second support plate 51, a discharge frame 52, a first torsion spring 53 and a rotating plate 54, and the first support plate 1 is provided with a second support plate 51 on both front and rear sides of the left part. A discharge frame 52 is rotatably connected between the top of the second support plate 51, the first torsion spring 53 is sleeved on the front and rear sides of the discharge frame 52, and the two ends of the first torsion spring 53 are respectively connected to the second support plate 51. And on the discharge frame 52, the front side of the discharge frame 52 is connected with a rotating plate 54, and the rotating plate 54 is rotationally connected with the second support plate 51 located at the front side.

[0065] When people need to clean the filter, people can place the filter in the discharge frame 52, then the weigh...

Embodiment 3

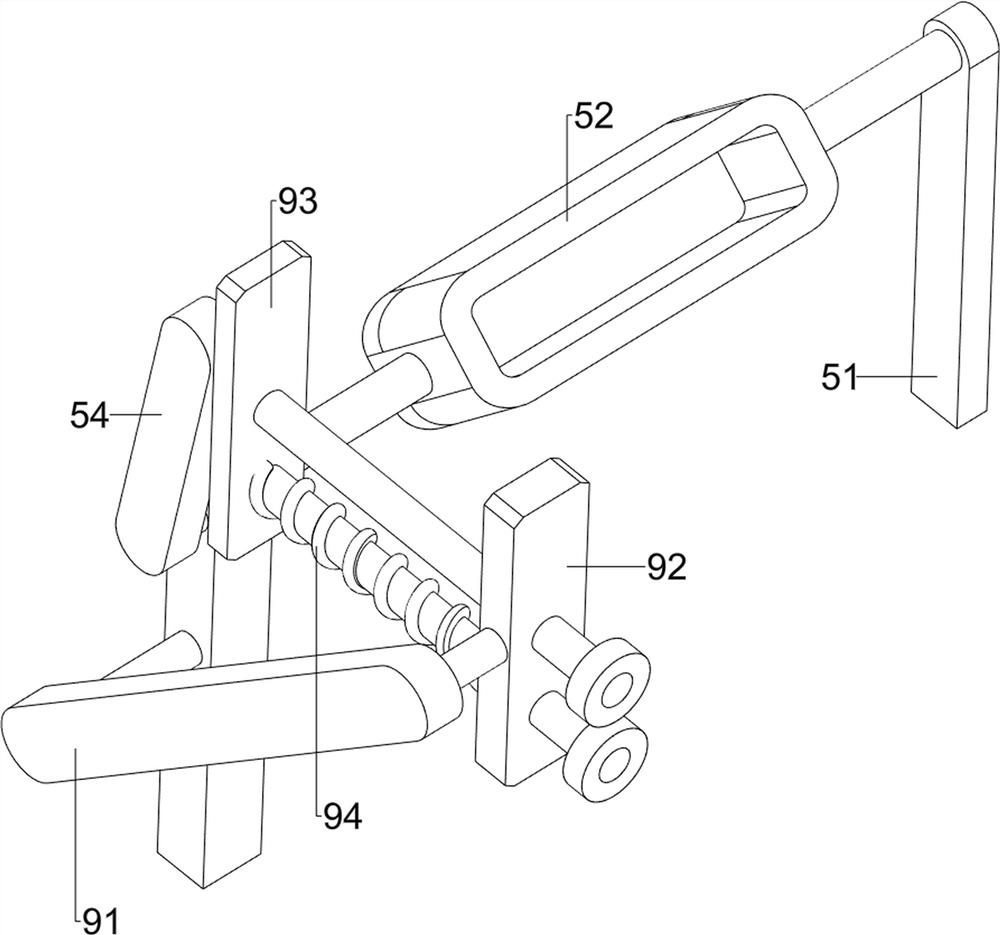

[0073] In a preferred embodiment of the present invention, as figure 1 and Figure 6-Figure 7 As shown, the opening and closing auxiliary mechanism 9 is also included, and the opening and closing auxiliary mechanism 9 includes a fifth support plate 91, a sixth fixed plate 92, a moving plate 93 and a fifth spring 94, and the second support plate on the front side 51 middle part front sides are provided with the 5th supporting board frame 91, the 5th supporting board frame 91 tops are provided with the 6th fixed plate 92, are provided with movable plate frame 93 slidingly on the 6th fixed plate frame 92, mobile plate frame 93 and long column The rod 74 cooperates, and the fifth spring 94 is sleeved on the lower part of the movable plate frame 93, and the two ends of the fifth spring 94 are respectively connected to the sixth fixed plate 92 and the movable plate frame 93.

[0074] It is more laborious for people to manually control the spraying process of the cleaning liquid, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com