Automatic valve core cutting and detecting device

A detection device, valve core technology, applied in sorting and other directions, can solve the problems of time-consuming and laborious, reduce production efficiency, reduce labor costs of enterprises, etc., and achieve the effect of reducing labor costs, improving production efficiency, and saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

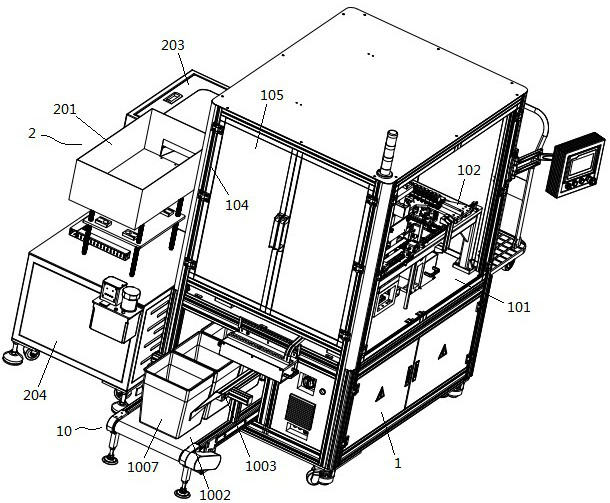

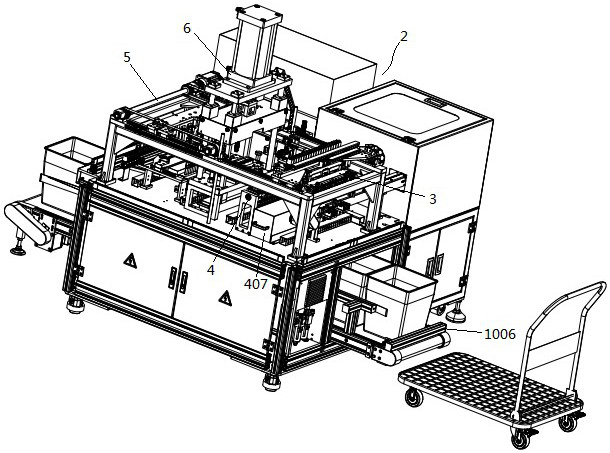

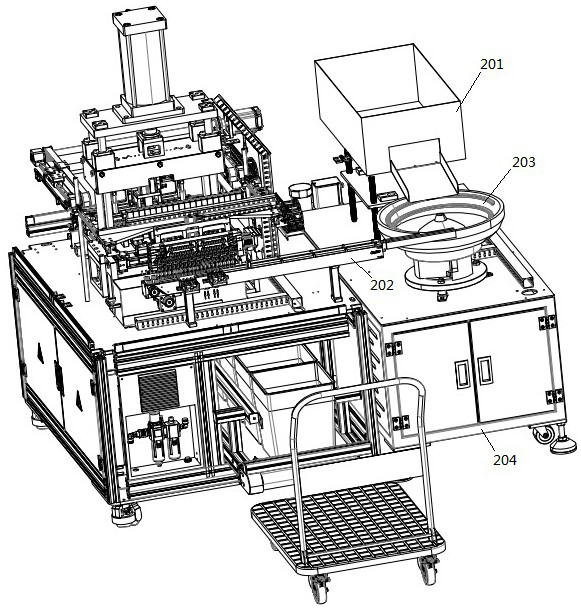

[0042] Embodiment 1: as Figure 1-15 As shown, an automatic valve core cutting detection device includes a chassis 1, a feeding mechanism 2, a front transfer mechanism 3, a posture detection mechanism 4, a rear transfer mechanism 5, an air hole cutting mechanism 6, and an air hole detection mechanism. Mechanism 7, good and defective product separating mechanism 8, defective product collecting mechanism 9 and good product unloading mechanism 10; Described cabinet 1 is provided with controller, and the top of cabinet 1 is workbench 101, and the top of workbench 101 is connected with large Support frame 102, the top of cabinet 1 is connected with frame 104, is connected with protective door 105 between frame 104; Described feeding mechanism 2 comprises material storage box 201, feeding device and feeding channel 202; Described feeding device is provided with On the side of the cabinet 1, the discharge port of the material storage box 201 is located above the feeding device; the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com