Edge straightening machine convenient to overhaul and used for wood processing

A technology for easy maintenance and straight edge machine, which is applied in the field of wood processing and can solve the problems of increasing the grinding time of wood edges.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

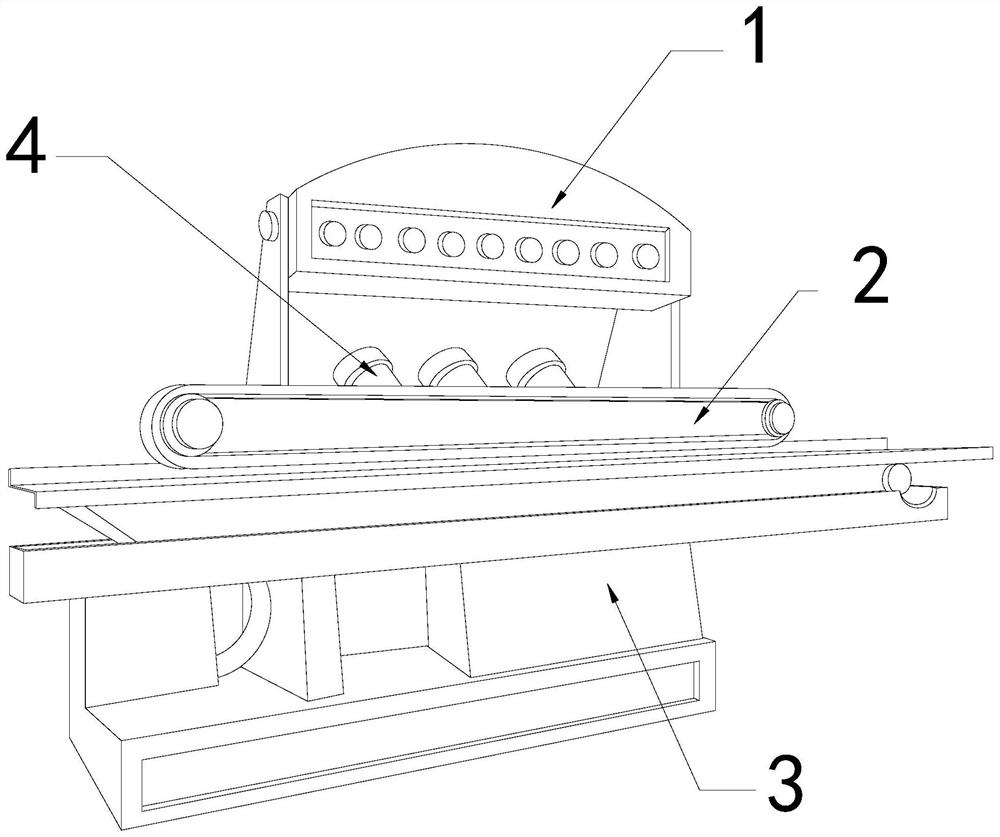

[0026] For example figure 1 -example Figure 5 Shown:

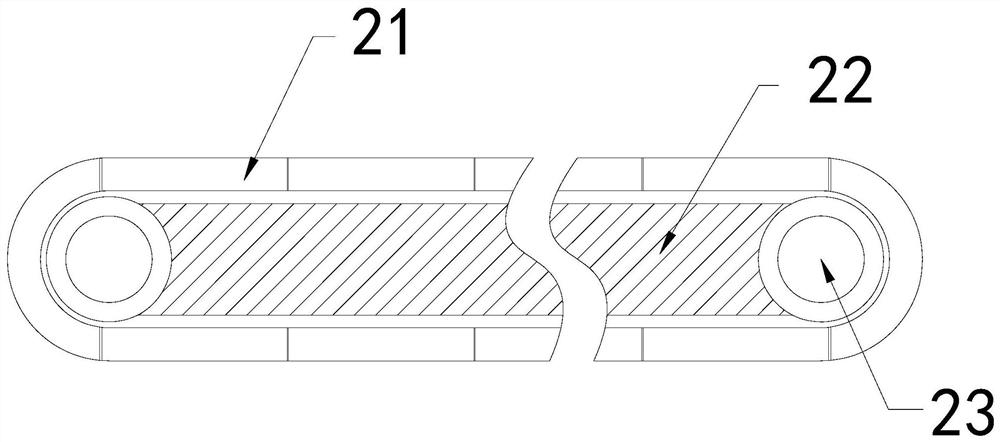

[0027] The invention provides a straight-edge machine for wood processing, which is convenient for maintenance. Its structure includes a control frame 1, a straight-edge mechanism 2, a base 3, and a driver 4. 4 is installed at the rear end of the straight side mechanism 2, the straight side mechanism 2 is connected with the control frame 1; The power roller 23 is movably engaged, and the connecting rod 22 and the power roller 23 are of an integrated structure.

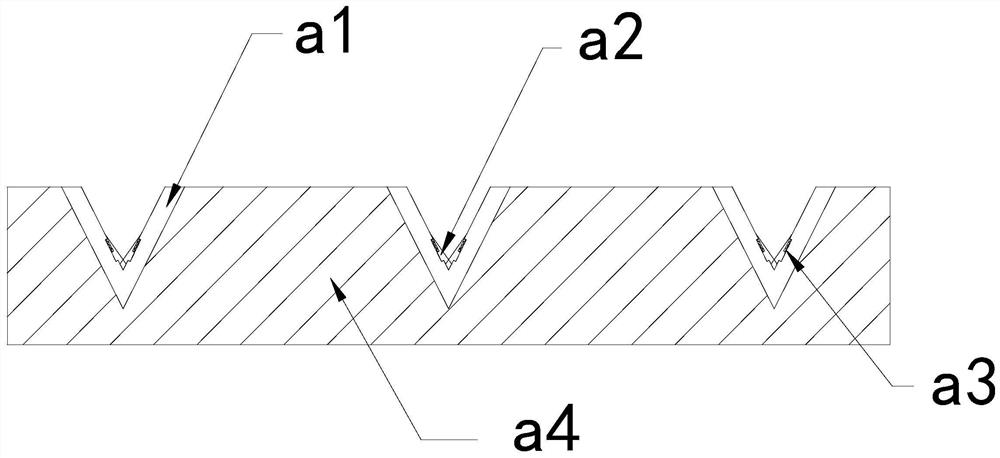

[0028] Wherein, the bearing surface 21 includes a guiding cavity a1, an extrapolating block a2, a pulling strip a3, and a plate body a4, the guiding cavity a1 is embedded in the inner position of the plate body a4, and the outer pushing block a2 and the guiding cavity a1 The inner side is movable and engaged, and the pull bar a3 is installed between the pusher block a2 and the guide cavity a1, and the guide cavity a1 has a triangular groove structure, which can...

Embodiment 2

[0034] For example Image 6 -example Figure 8 Shown:

[0035] Wherein, the pushing block a2 includes an extending block c1, a fitting plate c2, an engaging ring c3, and a bottoming plate c4, the extending block c1 and the fitting plate c2 are in clearance fit, and the connecting ring c3 is installed on the extending block c1 Between the base plate c4 and the bonding plate c2, the base plate c4 and the bonding plate c2 are of an integrated structure. There are six overhanging blocks c1, and they are evenly distributed in parallel on the bonding plate c2. Through the connecting ring c3, the The overhanging block c1 is pushed out.

[0036] Wherein, the overhanging block c1 includes a contact plate c11, a middle block c12, a bottom block c13, and a resilient piece c14. The contact plate c11 is movably engaged with the bottom block c13 through the middle piece c12. Between the bottom block c13 and the bottom of the contact plate c11, the upper layer of the contact plate c11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com