A kind of textile lint processing method

A processing method and technology for lint, applied in the field of textile lint processing, can solve the problems of small artificial shaking, affecting the appearance of textile lint, and dust falling off of textile lint, so as to achieve the effect of smooth and smooth cotton lint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

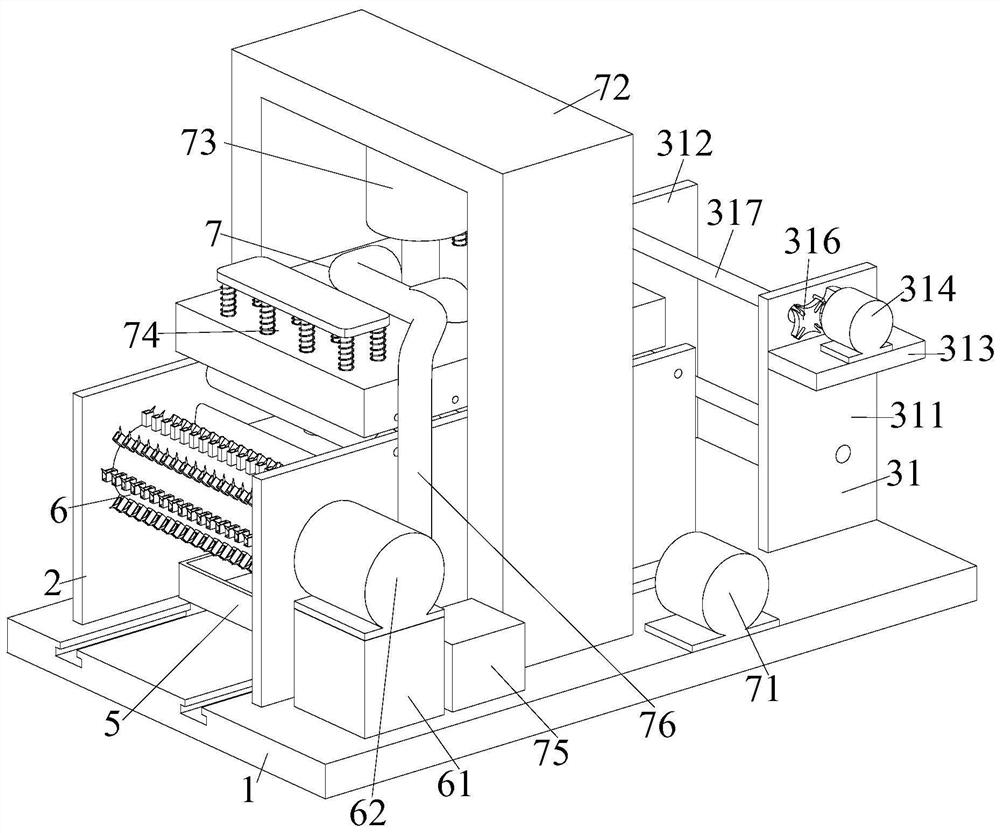

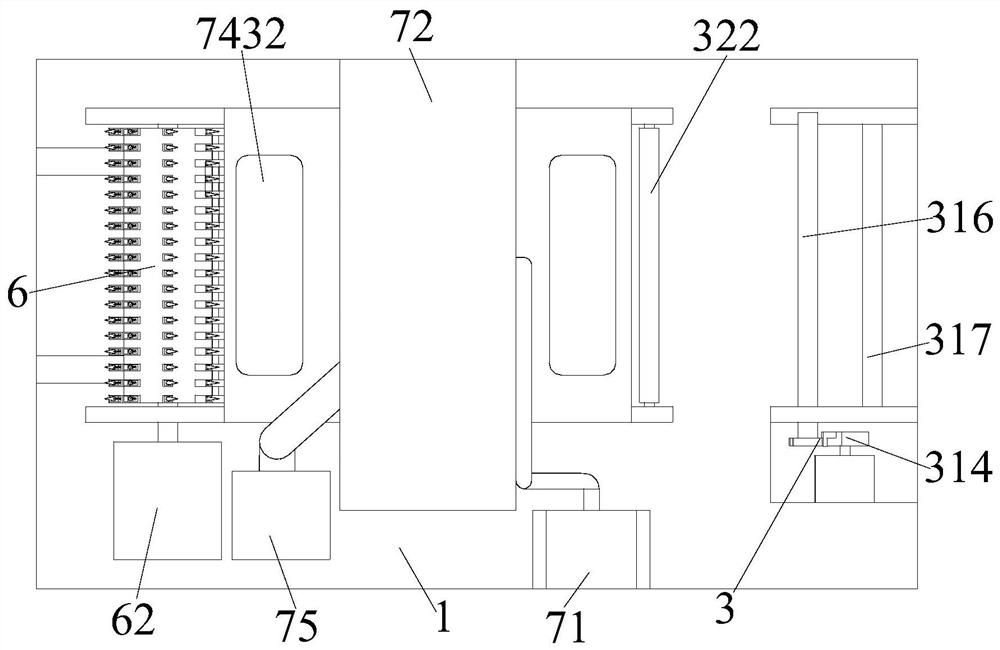

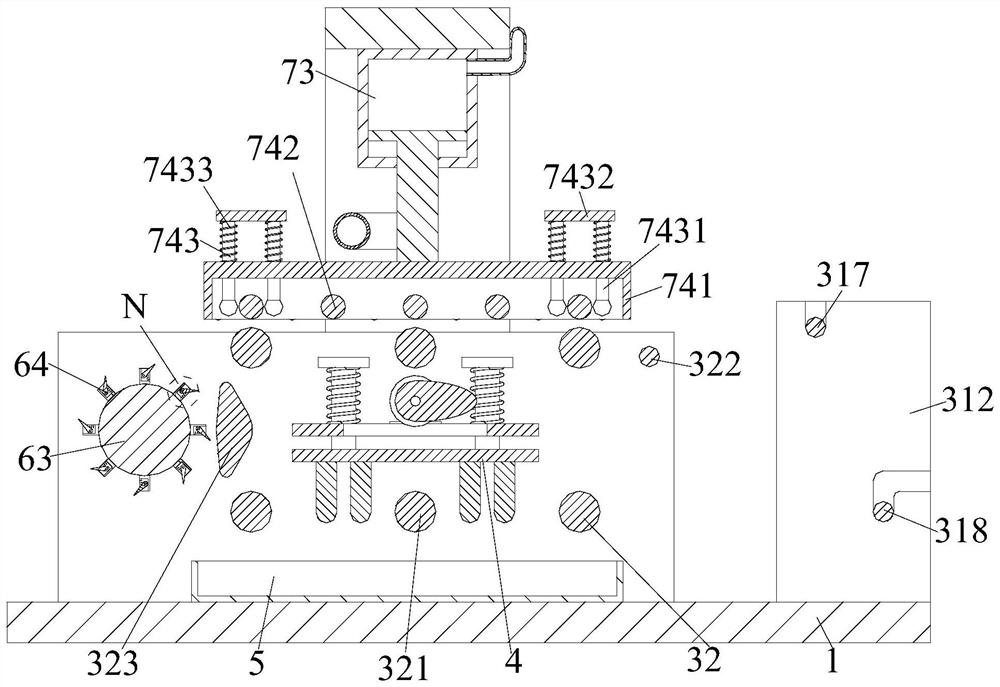

[0040] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 7 , to further elaborate the present invention.

[0041] A kind of textile lint processing method, concrete processing method is as follows:

[0042] S1. Loading: Manually remove the feeding rod 318, and manually place the rolls of textile lint on the feeding rod 318, then install the feeding rod 318 back between the front mounting plate 311 and the rear mounting plate 312 , and the outer end of the textile lint is manually installed on the winding rod 317 after bypassing the supporting mechanism 32;

[0043] S2. Shaking off dust: the vibration motor 42 is rotated to make the cam 43 squeeze the sliding plate 44, thereby causing the vibration rod 47 to lift and shake off the larger dust in the textile lint;

[0044] S3. Carding lint: After the dust is shaken, the winding motor 314 rotates, causing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com