Packaging system and method for food production

一种食品、封装设备的技术,应用在包装、运输包装、运输和包装等方向,能够解决饼干泄露、烫伤、封装口破裂等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

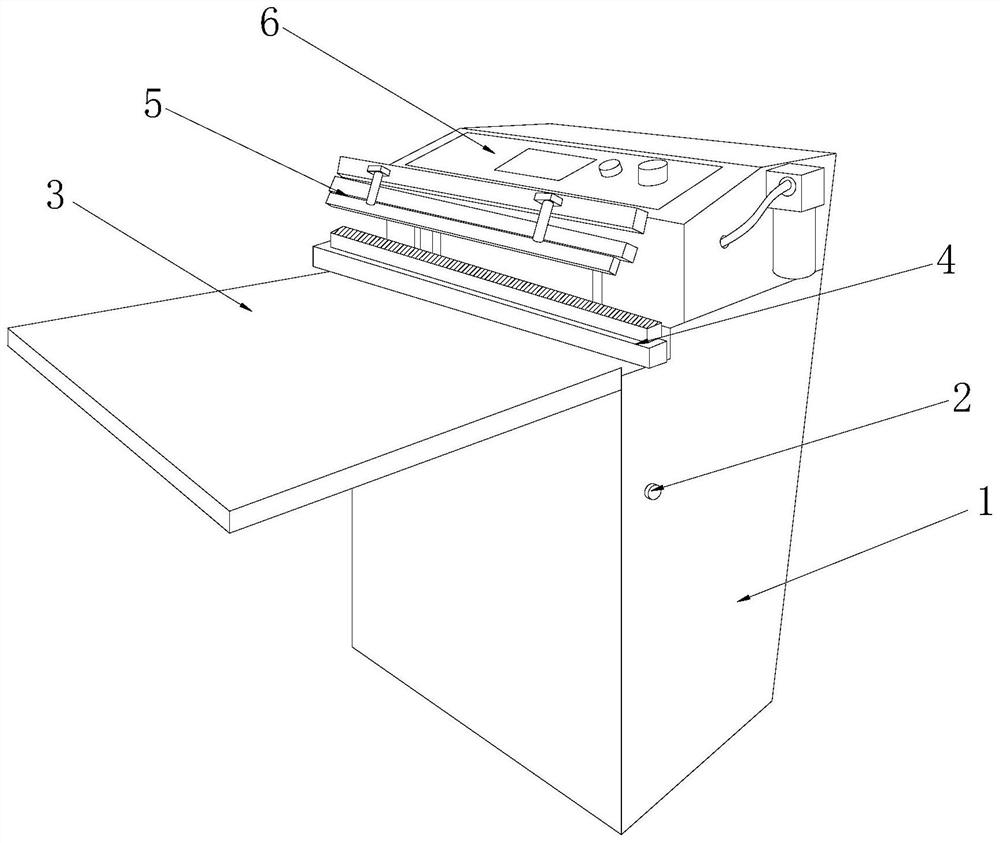

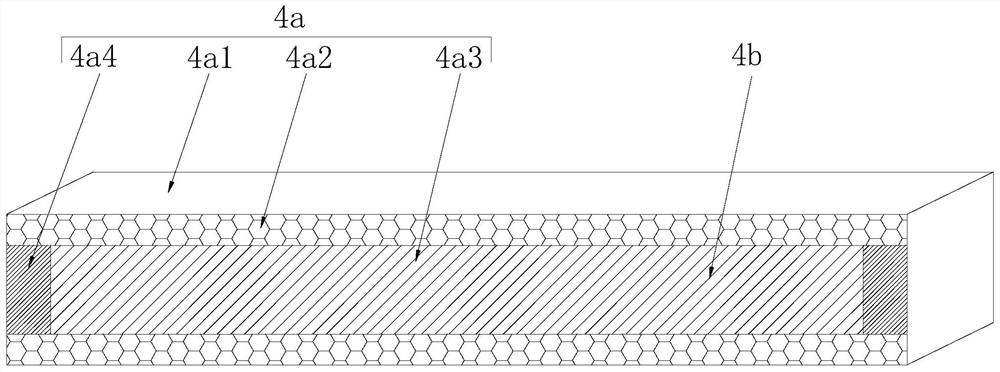

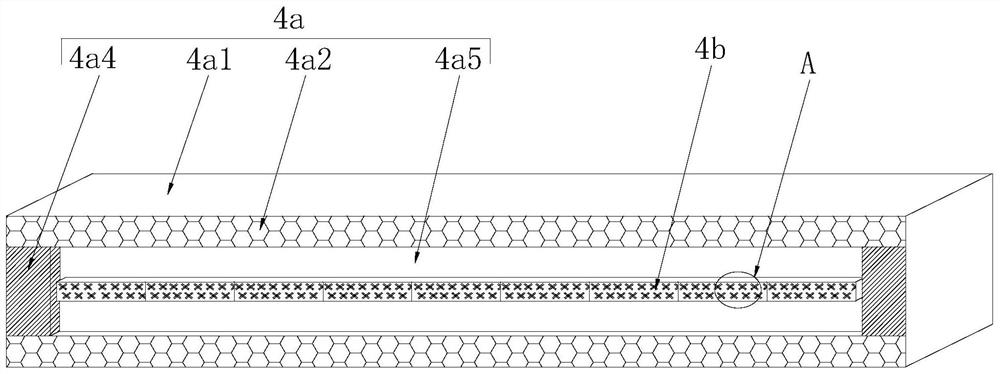

[0027] Such as Figure 1-Figure 5 As shown, the present invention provides a technical scheme of packaging system and method for food production:

[0028] Such as Figure 1-Figure 3 As shown, a packaging system and method for food production, its structure includes a device main body 1, an air hole 2, a workbench 3, an anti-melting device 4, a heating rubber roller 5, and a control panel 6, and the air hole 2 is located in the equipment The right side of the main body 1 is an integrated structure. The workbench 3 is installed on the middle and upper part of the front surface of the equipment main body 1 and connected by electric welding. connected, the heating rubber roller 5 is located above the anti-melting device 4, the control panel 6 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com