High polymer grouting protective structure of manual digging pile and its construction method

A technology of artificially digging piles and protective structures, which is applied in the direction of foundation structure engineering, sheet pile walls, buildings, etc., and can solve problems that affect construction quality and construction progress, cannot fill piles in time, and are inconvenient for material transportation and stacking. , to reduce the possibility of local instability of the soil, improve support strength and waterproof performance, and improve underground operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

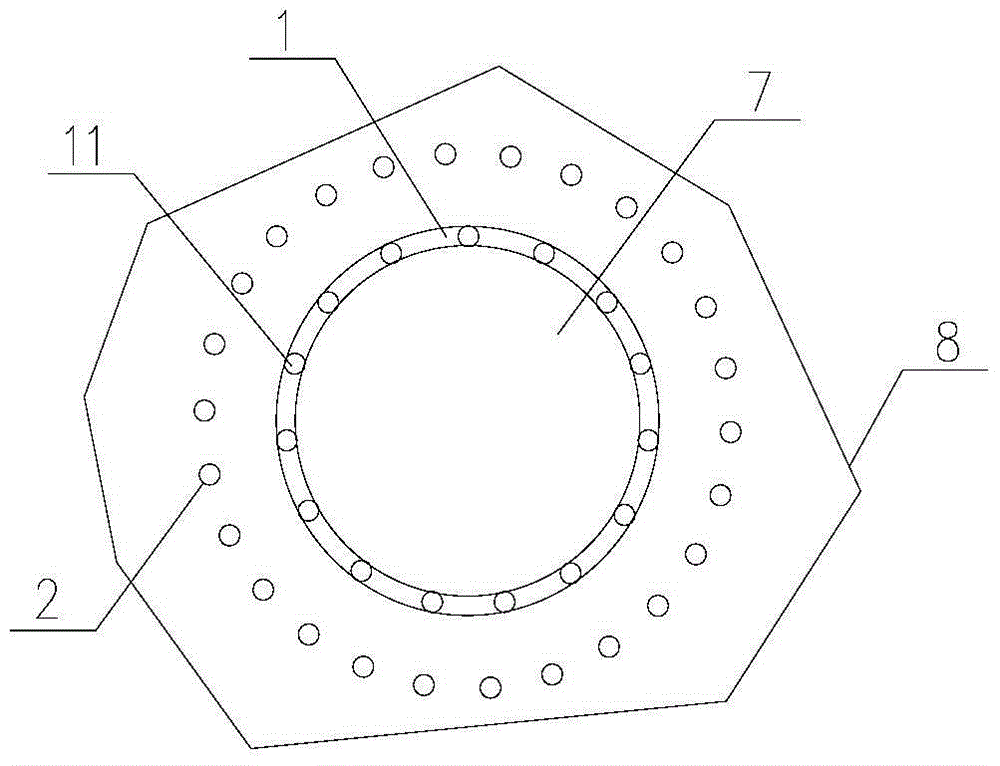

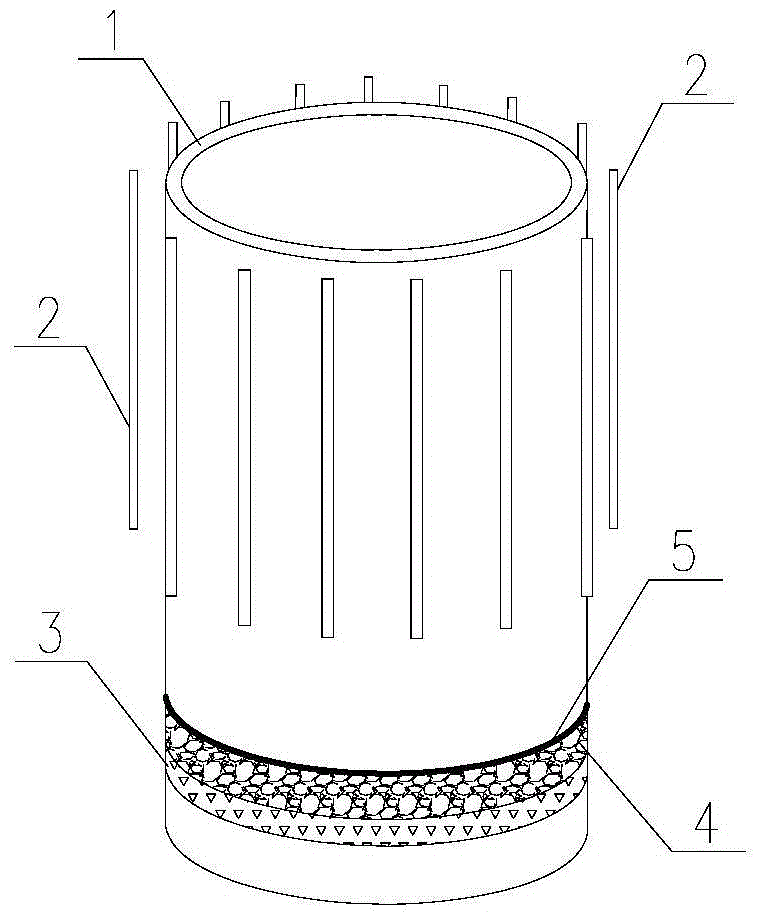

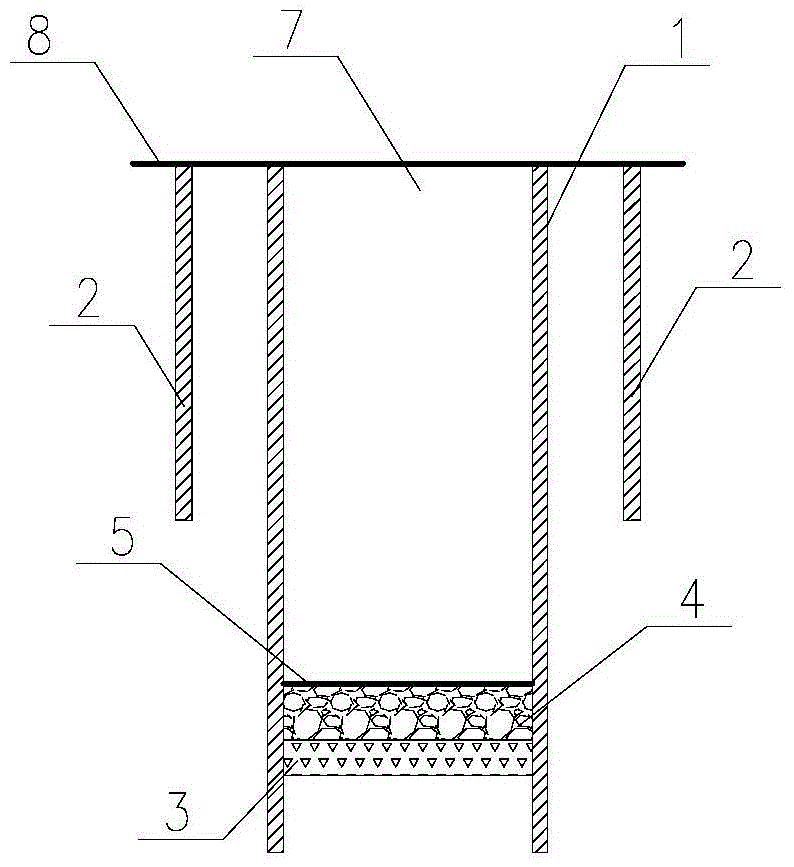

[0045] see figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 In the present embodiment, the artificial excavation pile high polymer grouting protection structure is to set the pile hole wall to be a waterproof support ring 1 formed by high polymer grouting; the top of the waterproof support ring 1 is equipped with a belt protection ring The pressure grouting ring 10 of the grouting hole 11, on the periphery of the waterproof support ring 1, there are reinforcing columns 2 formed by high polymer grouting at intervals along the circumference; Lay mats to form a lime reinforcement layer 3, pave graded crushed stones on the lime reinforcement layer 3 to form a crushed stone waterproof layer 4, and install a pressure grouting plate 5 on the top surface of the crushed stone waterproof layer 4 through expansion bolts. The bottom grouting hole 6 is opened on the plate 5, and the polymer grouting liquid injected through the bottom grouting hole 6 penetrates into the gaps o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com