Mechanical carrying device of fully mechanized excavation face

A technology for handling devices and working surfaces, which is applied in transportation and packaging, underground transportation, and earth-moving drilling and mining, etc., can solve problems such as threats to the personal safety of workers, high labor intensity of workers, and serious potential safety hazards, so as to ensure personal safety and ensure personnel safety. The effect of safety and physical labor reduction with equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

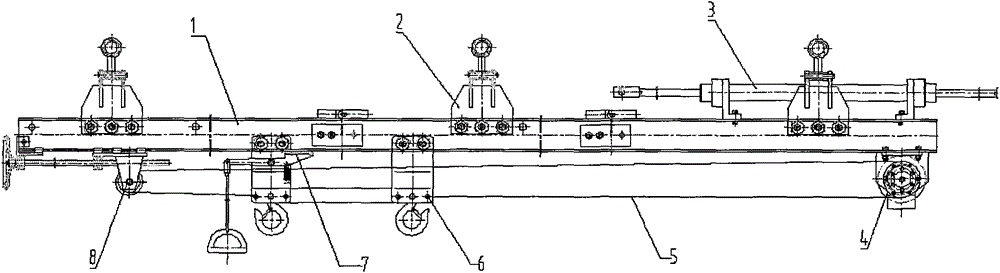

[0018] see figure 1 As shown, it is a schematic diagram of the mechanized conveying device for fully mechanized excavation face of the present invention. The invention has a connected main beam (1), a set of main beam pulleys (2), a main beam moving oil cylinder (3), a hydraulic winch (4), a traction wire rope (5), a set of handling Tackle block (6), a set of braking device (7) and a set of tension tail wheel (8).

[0019] The main girder (1) of the mechanized handling device in the fully mechanized excavation working face is connected by multiple I-beams, and the length depends on the distance to be transported. Meet the angle change of the roadway up and down 15°;

[0020] The main girder block (2) of the mechanized handling device of the fully mechanized excavation face is suspended on the roof anchor rod, and its levelness is adjusted by a lever block. run along the roller;

[0021] The oil cylinder (3) of the mechanized handling device in the fully mechanized excavati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com