Sludge source reduction device and sludge source reduction process

A sludge and process technology, applied in the field of sewage treatment, can solve the problems affecting the actual effect of sewage treatment, high cost of sludge treatment and disposal, and entry of pollutants, so as to achieve sludge source reduction, low equipment cost, and prevention of continuous pollution. subsidence effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

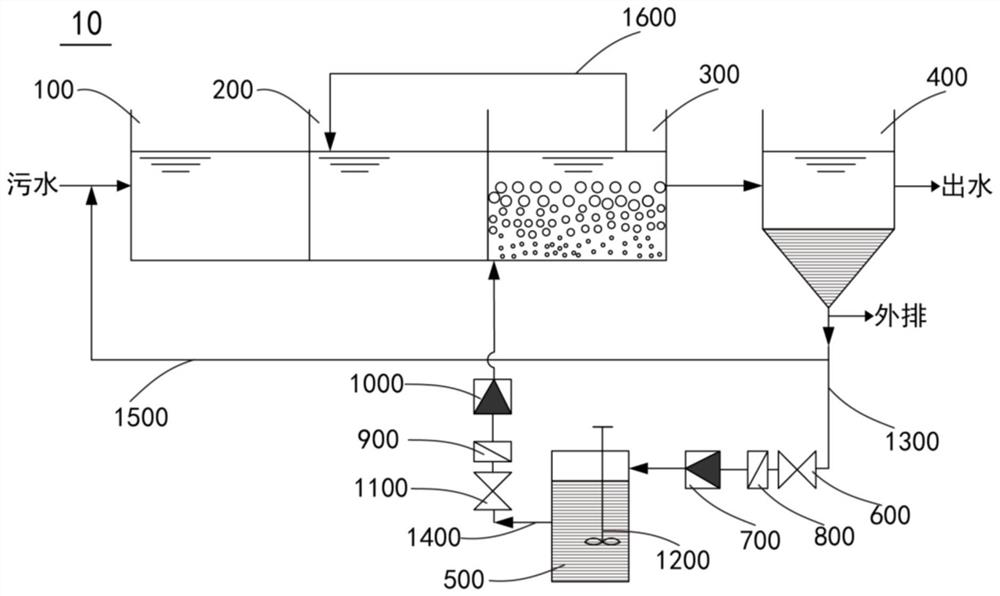

[0088] This embodiment provides a sludge source reduction device 10 .

[0089] see figure 1 As shown, a sludge source reduction device 10 includes an anaerobic tank 100, an anoxic tank 200, an aeration tank 300, a secondary sedimentation tank 400, a biological selector 500, a first driving pump 600, and a first flow meter 700. , a first valve assembly 800, a second drive pump 900, a second flow meter 1000, a second valve assembly 1100, a stirring mechanism 1200, a mud inlet pipe 1300, a mud outlet pipe 1400 and a return pipe.

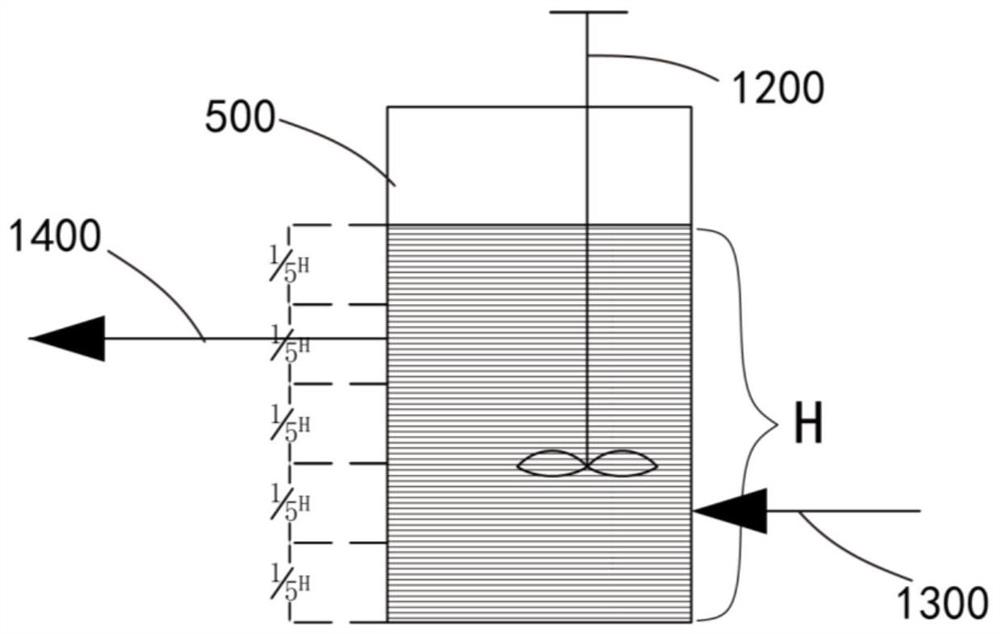

[0090] Along the flow direction of the sewage, the anaerobic tank 100 , the anoxic tank 200 , the aeration tank 300 , the secondary sedimentation tank 400 and the biological selector 500 are connected in sequence. The secondary sedimentation tank 400 is connected to the biological selector 500 through the mud inlet pipeline 1300 . The biological selector 500 is connected to the aeration tank 300 through the mud outlet pipe 1400 . The secondary sedime...

Embodiment 2

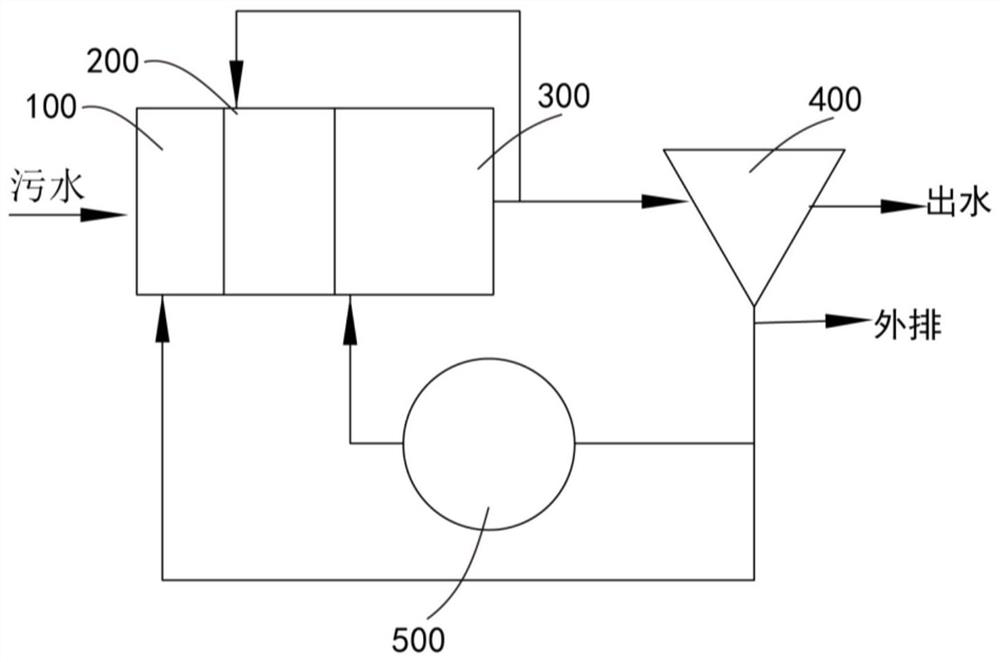

[0096] This embodiment provides a sludge source reduction process.

[0097] see figure 2 As shown, a sludge source reduction process includes the following steps:

[0098] The sewage passes through the anaerobic tank 100, the anoxic tank 200 and the aeration tank 300 for anaerobic treatment, anoxic treatment and aeration treatment respectively.

[0099] The mixed liquid in the aeration tank 300 passes through the secondary sedimentation tank 400 for solid-liquid separation treatment.

[0100] Part of the excess sludge in the secondary sedimentation tank 400 enters the biological selector 500 at a first preset exchange frequency of 4 times / d and stays for a preset time, and the preset time is 10 days. The sedimented sludge in the secondary sedimentation tank 400 enters the biological selector 500 at a sludge return ratio of 10%. Part of the excess sludge in the secondary sedimentation tank 400 is returned to the anaerobic tank 100 .

[0101] The sludge and supernatant gene...

Embodiment 3

[0104] This embodiment uses the sludge source reduction device 10 in Example 1 and the sludge source reduction process in Example 2 to treat sewage.

[0105] In this embodiment, the sewage treatment capacity is 20000m 3 / d, which is 833.33m 3 / h. The hydraulic retention time of sewage in the anaerobic tank 100, the anoxic tank 200, and the aeration tank 300 were 2h, 2h, and 6h, respectively, and the sludge concentration of the aeration tank 300 was 2500 mg / L.

[0106] The quality of the absolute dry sludge discharged from the biological selector 500 every day is as follows: volume of aeration tank 300 = hydraulic retention time x treatment scale = 6h x 833.33m 3 / h=4999.98m 3 ; 300 absolute dry sludge mass in aeration tank M = volume of aeration tank 300 × sludge concentration = 4999.98m 3 ×2500mg / L=12499.95kg; the sludge return ratio is 10%, the absolute dry sludge mass discharged into the biological selector 500 every day is 12499.95kg × 10%=1249.995kg, that is, the abso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com