Soil foundation pit steel pipe pile composite supporting structure and construction method

A technology of foundation pit steel pipe and support structure, which is applied in basic structure engineering, excavation, sheet pile wall, etc., can solve the problems of single structure, high engineering cost and long construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

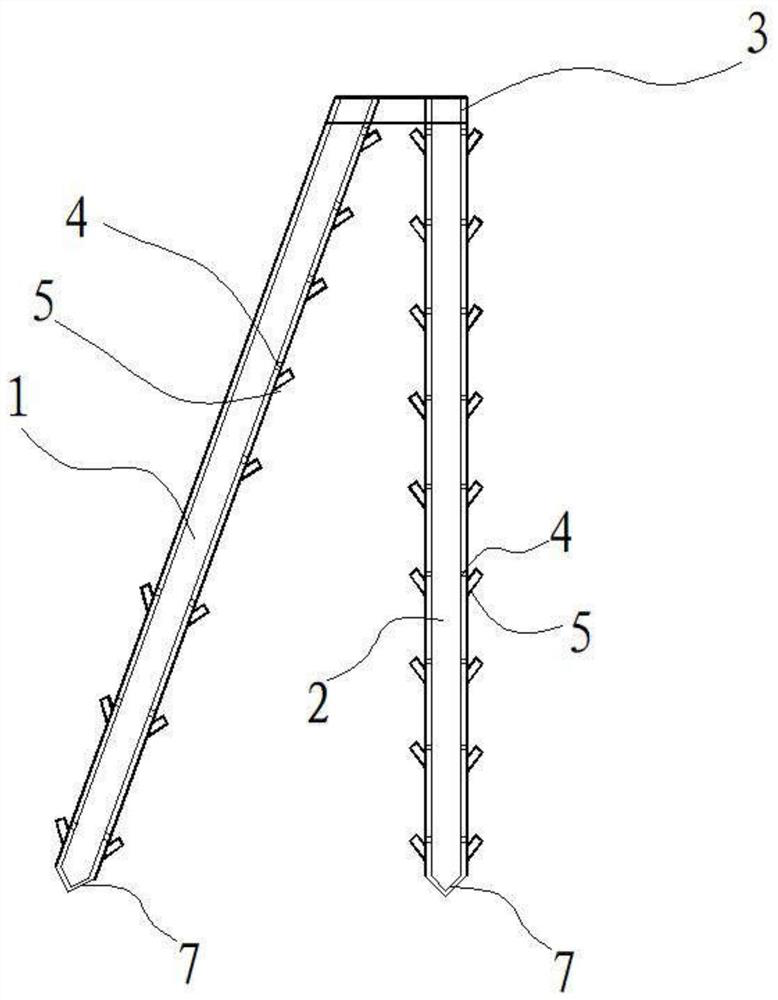

[0042] Such as figure 1 , Figure 5 , Image 6 , Figure 7 As shown, this embodiment includes a plurality of front row steel pipe piles 1 arranged in parallel and a plurality of rear row steel pipe piles 2 arranged in parallel, the front row steel pipe piles 1 and the rear row steel pipe piles 2 are one by one Correspondingly set, the top of the front row of steel pipe piles 1 and the top of the rear row of steel pipe piles 2 are fixedly connected through the top beam 3, and the front row of steel pipe piles 1 and the rear row of steel pipe piles 2 are clamped. Angle setting, the front row of steel pipe piles 1 and the rear row of steel pipe piles 2 form a portal structure system, specifically, in this embodiment, the front row of steel pipe piles The included angle of the direction is 70°-80°, the rear row of steel pipe piles 2 are vertically arranged, the bottom ends of the front row of steel pipe piles 1 and the rear row of steel pipe piles 2 are sealed, and the front ro...

Embodiment 2

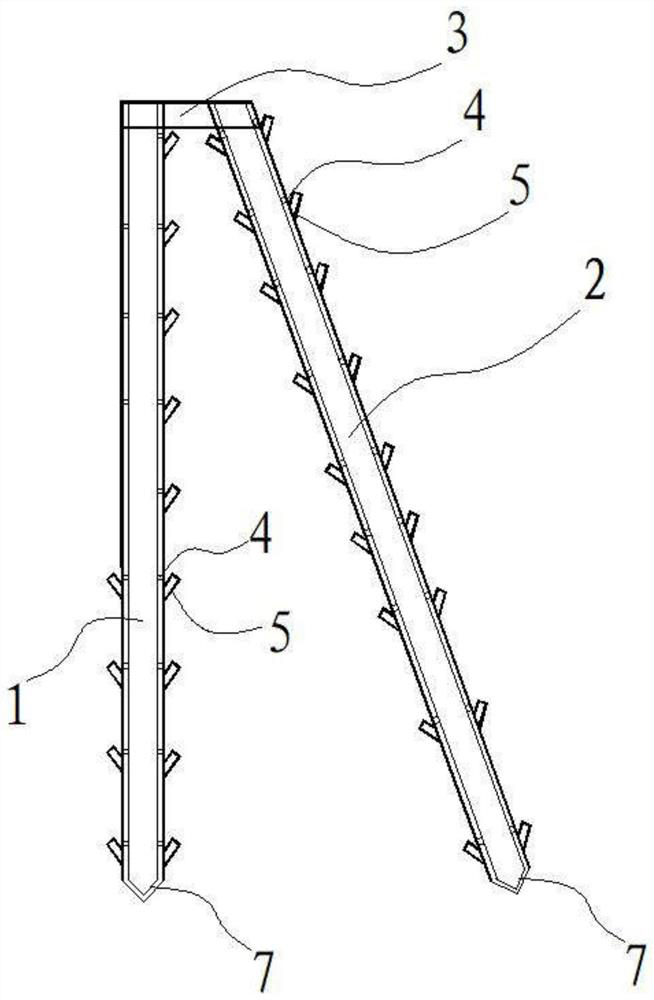

[0057] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that in this embodiment, the rear row of steel pipe piles 2 are arranged obliquely, and the included angle with the vertical direction is 70°-80°, and the front row The row of steel pipe piles 1 is arranged vertically,

Embodiment 3

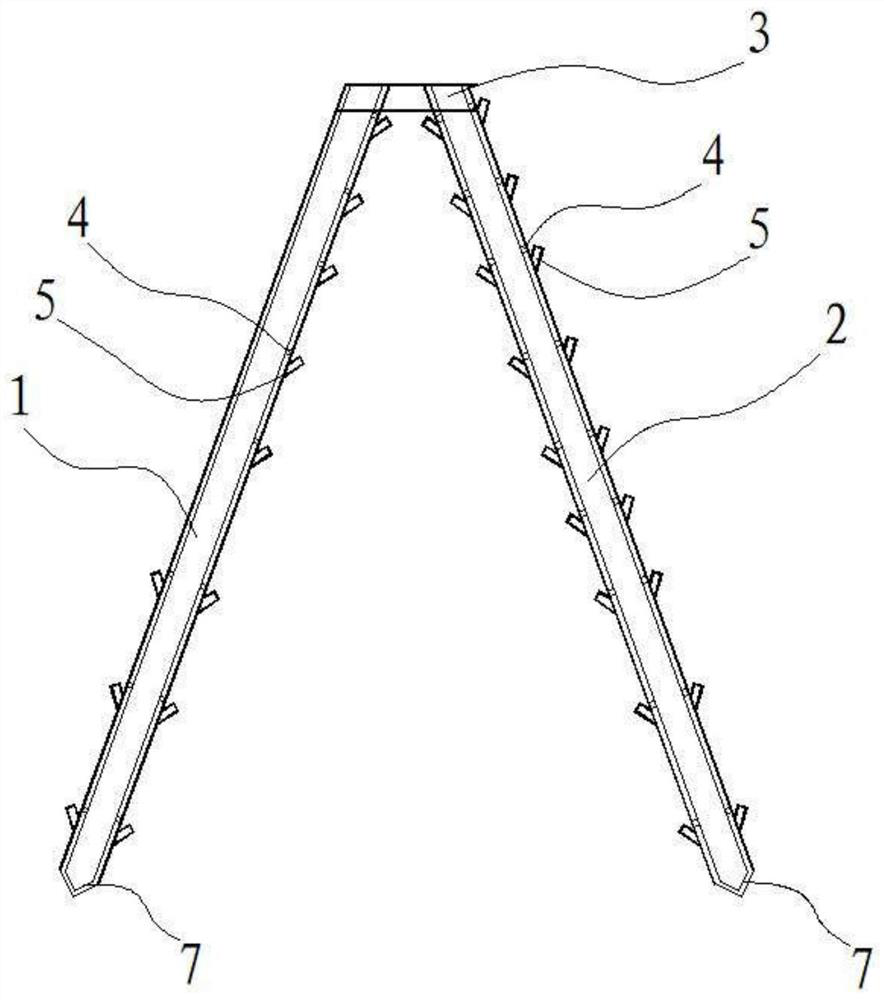

[0059] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that in this embodiment, the steel pipe piles 1 in the front row and the steel pipe piles 2 in the rear row are both inclined, and the tops of the two are fixed by the top beam 3, The bottoms of the two are inclined to the direction away from each other, and the angle between the two and the vertical direction is 70°-80°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com