Multi-stage central sleeve hydraulic cylinder structure capable of extending and retracting stage by stage

A hydraulic cylinder and bushing technology, which is applied in the field of hydraulic cylinders, can solve problems such as out-of-order pistons, achieve load balance and avoid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0028] It is worth noting that the orientation words such as "up" and "down" involved in this article are all determined relative to the perspective of the drawings, and are only for the convenience of description, and cannot be understood as limitations on the technical solution.

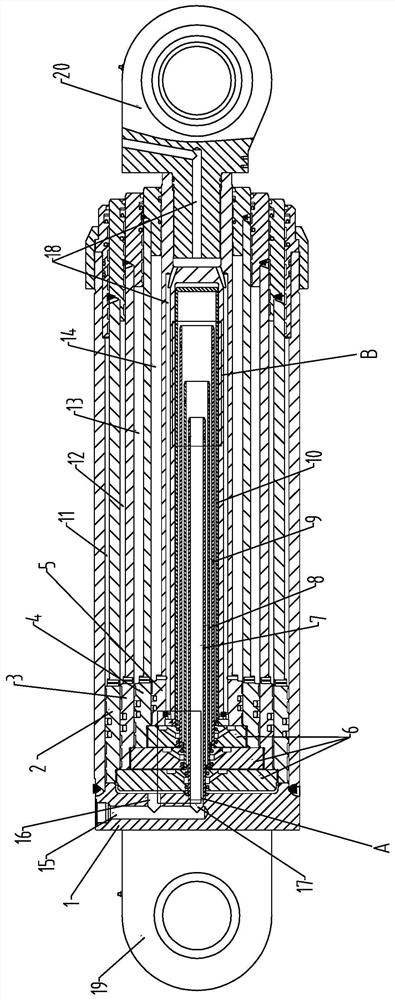

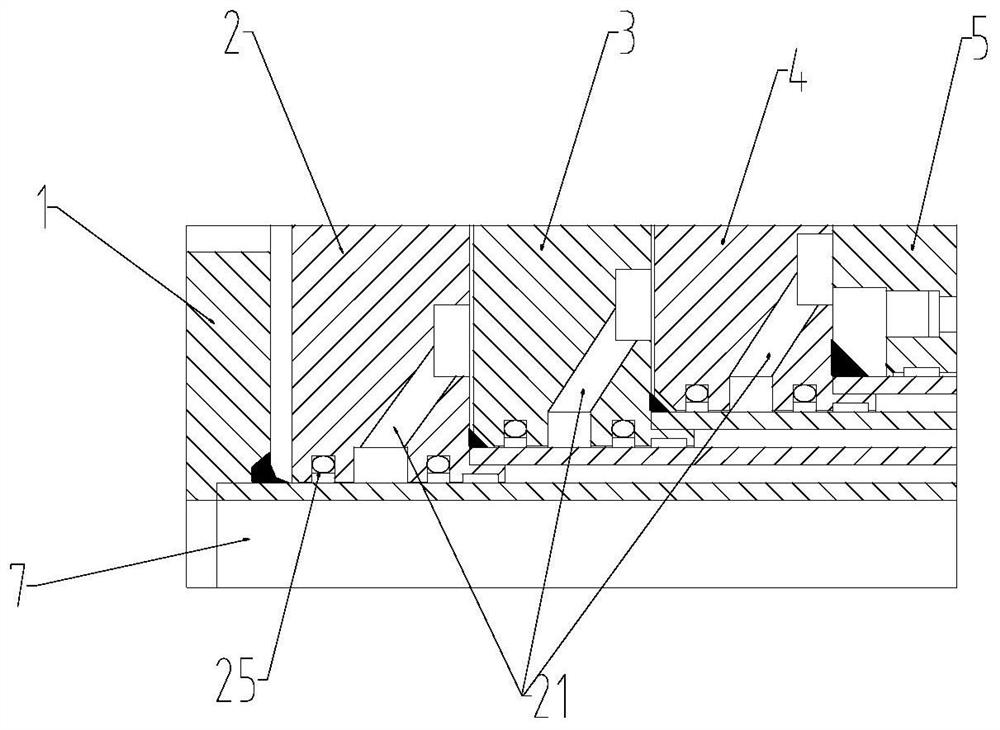

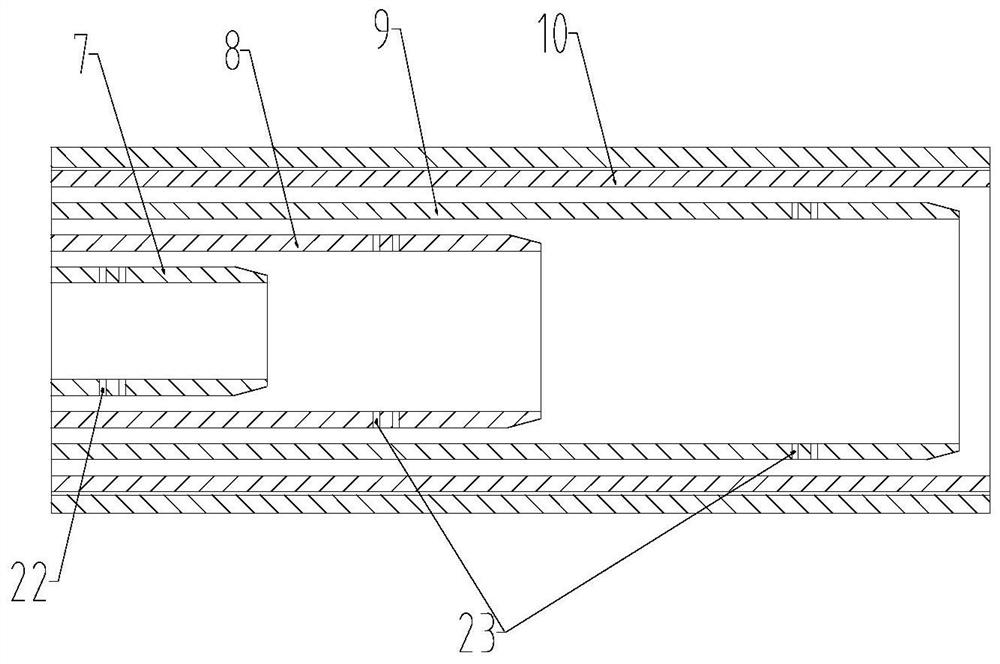

[0029] A multi-stage central sleeve hydraulic cylinder structure that can be extended and retracted step by step, including a cylinder body 1, a multi-stage intermediate cylinder and a piston rod 5, wherein the previous intermediate cylinder in the multi-stage intermediate cylinder Set outside the last intermediate cylinder of the multi-stage intermediate cylinders, the cylinder 1 is set outside the first intermediate cylinder of the multi-stage intermediate cylinders, and the last intermediate cylinder of the multi-stage intermediate cylinders is sleeved located outside t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com