Two-degree-of-freedom quasi-zero-stiffness low-frequency vibration isolation device

A quasi-zero stiffness and degree of freedom technology, applied in the field of two-degree-of-freedom quasi-zero stiffness low-frequency vibration isolation devices, can solve problems such as being difficult to meet, achieve excellent vibration isolation performance, reduce the initial vibration isolation frequency, and widen the isolation The effect of frequency bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

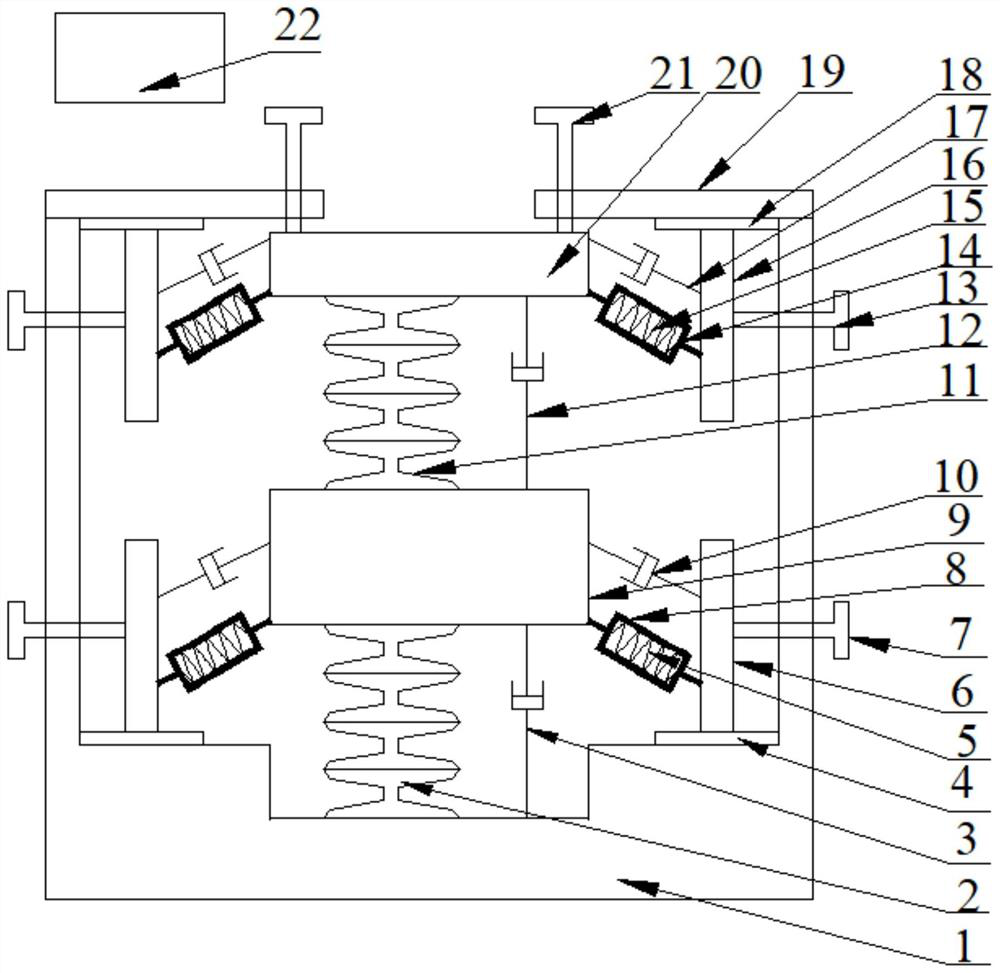

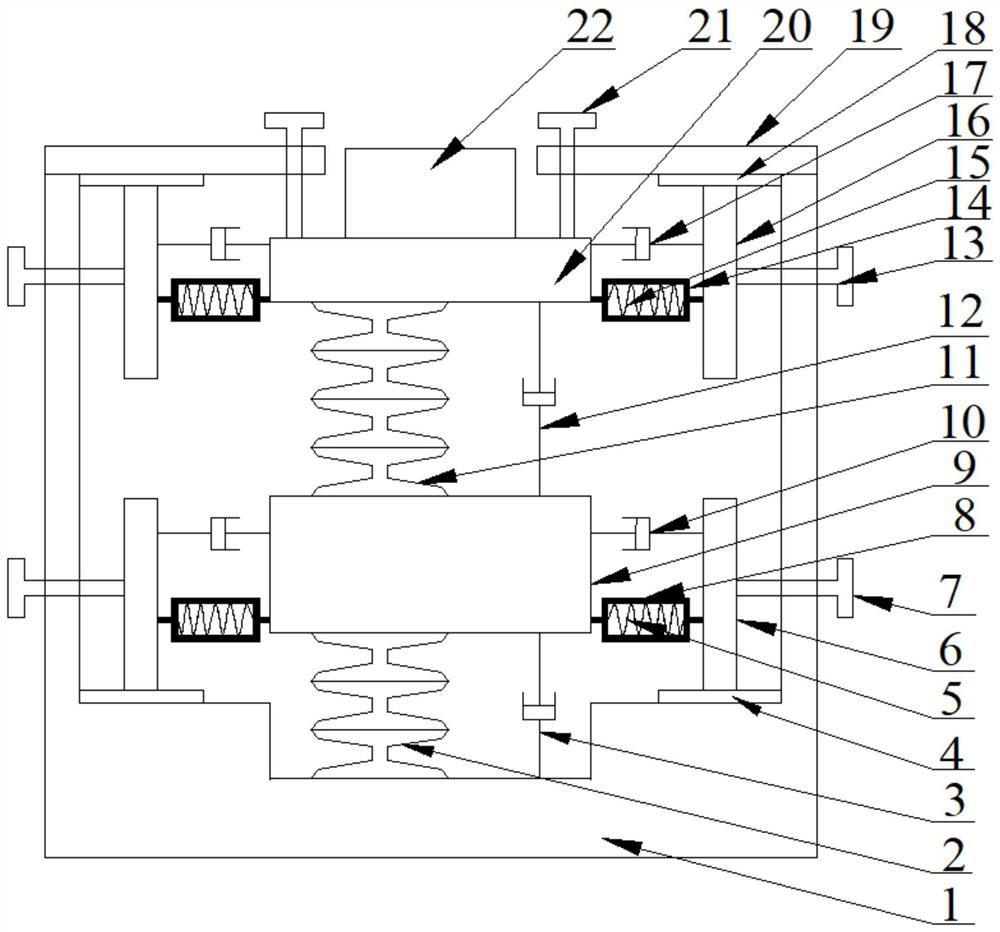

[0026] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0027] Such as Figure 1-6 As shown, the two-degree-of-freedom quasi-zero-stiffness low-frequency vibration isolation device of this embodiment includes a base 1, an upper quasi-zero-stiffness vibration isolator, a lower quasi-zero-stiffness vibration isolator, a supporting plate 20, an intermediate mass 9, two The upper horizontal movement mechanism, the two lower horizontal movement mechanisms and the vertical movement mechanism 21, the support plate 20 is arranged horizontally above the intermediate mass 9, and the support plate 20 is used to place the vibration-isolating body 22;

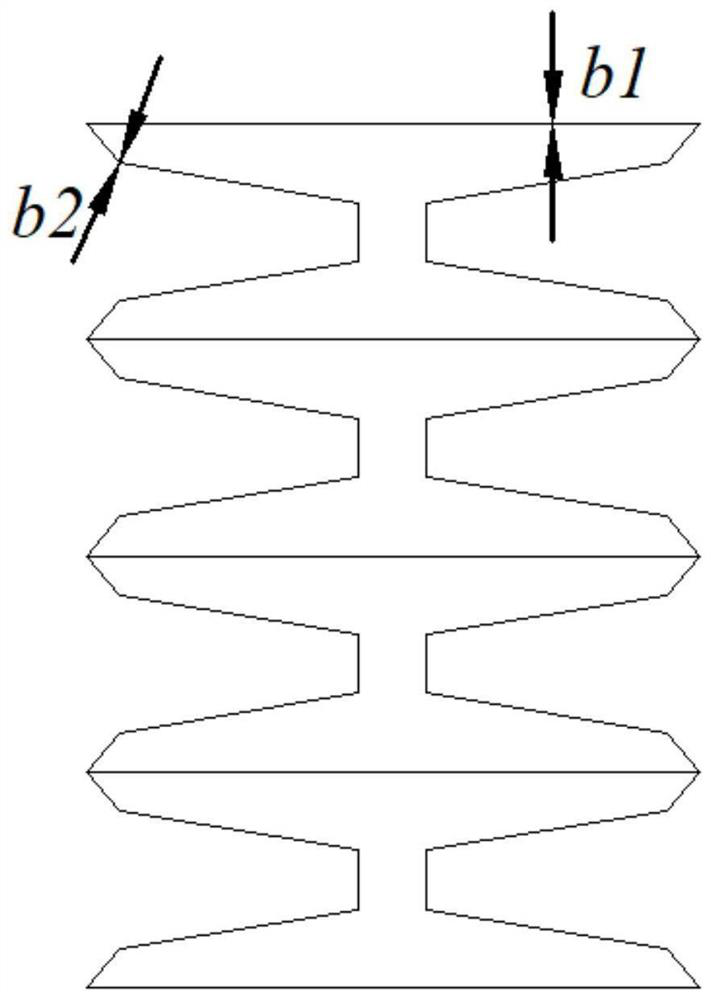

[0028] The upper quasi-zero stiffness vibration isolator includes an upper nonlinear spring 15, an upper nonlinear spring outer guide sleeve 14 and an upper vertical planar spring 11, and the upper and lower ends of the upper vertical planar spring 11 are re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com