Faucet structure of valve element offset temperature adjusting valve assembly

A faucet and temperature regulating valve technology, applied in the field of bathroom faucets, can solve the problems of limited effective operating angle, unfavorable precise flow adjustment, and large operating force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

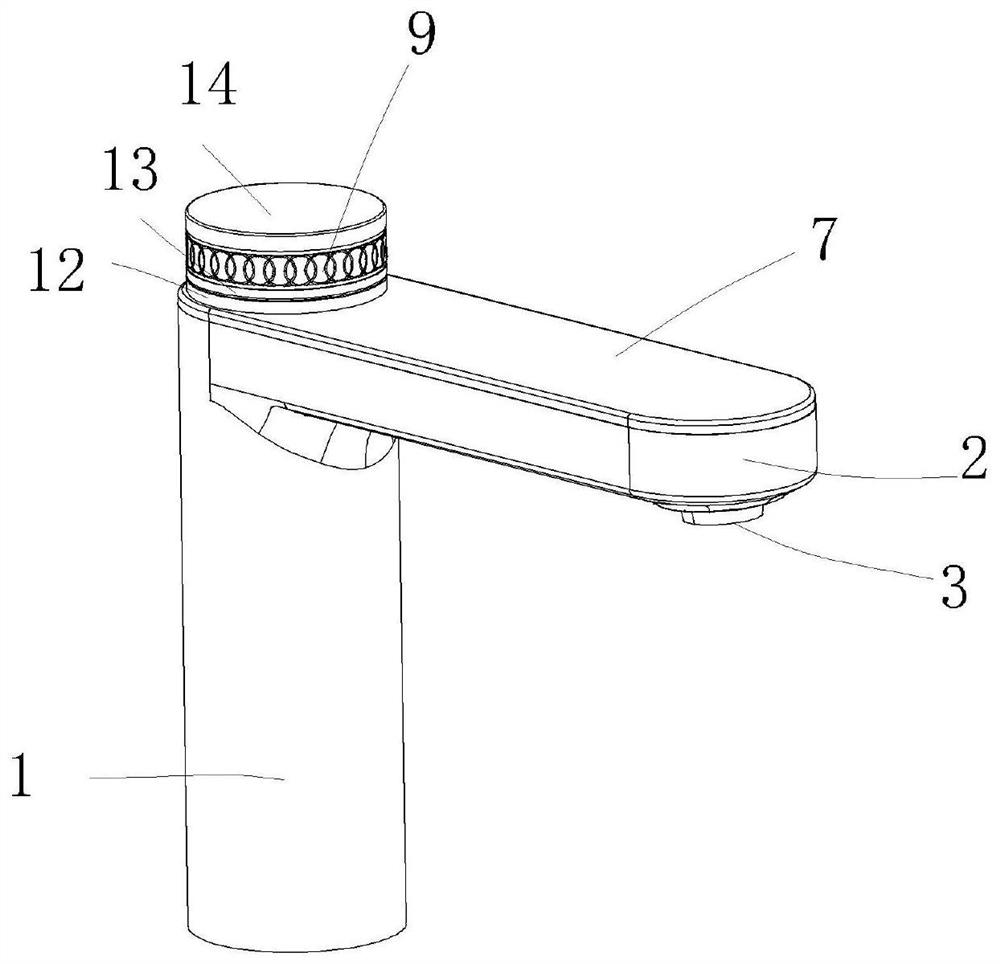

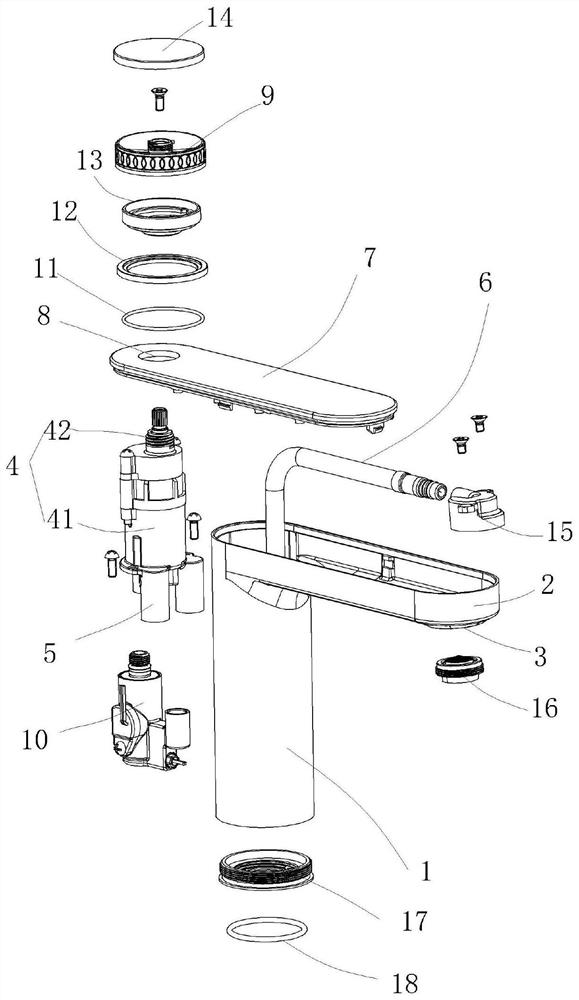

[0015] figure 1 and figure 2 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention; figure 2 It is a schematic diagram of the split structure of the present invention.

[0016] See figure 1 and figure 2 , a water faucet structure of a spool offset thermostat valve assembly, comprising a vertical cylinder 1, a horizontal faucet 2 is integrally formed on the top of the vertical cylinder, and a water outlet 3 is provided at the outer end of the horizontal faucet, so Inside the vertical cylinder, a spool offset mixing valve body 4 is fixed by round head screws, two water inlet terminals 5 are fixed at the bottom end of the spool offset mixing valve body, and a water inlet terminal 5 is fixed inside the horizontal faucet. A hose 6, the hose is connected between the water outlet and the water outlet of the spool offset mixing valve body, a display panel 7 is arranged on the top of the spool offset mixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com