Battery interface improvement method and battery interface improvement system

A battery and interface technology, which is applied in the direction of secondary battery charging/discharging, secondary batteries, battery pack components, etc., can solve the problems of insufficient electrolyte infiltration, long preparation process time, black spots, etc., and improve the battery interface The effect of analyzing lithium and black spots, improving the infiltration efficiency and prolonging the service life of the battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

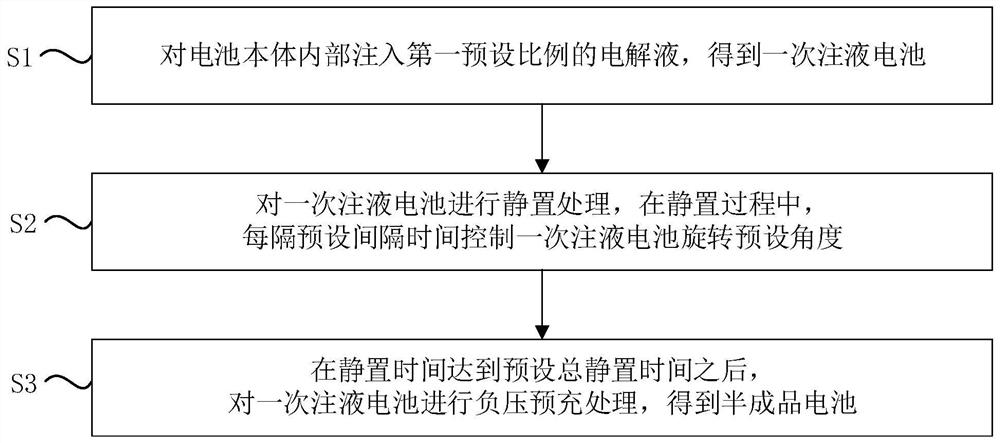

[0036] figure 1 It is a flowchart of a method for improving the battery interface provided by Embodiment 1 of the present invention. This embodiment is applicable to improving the application scene of the negative electrode sheet lithium or black spots of the lithium battery in the battery manufacturing process. The method can be configured by There are specific algorithms for battery preparation software and hardware to execute, specifically including the following steps:

[0037] Such as figure 1 As shown, the method for improving the battery interface includes the following steps:

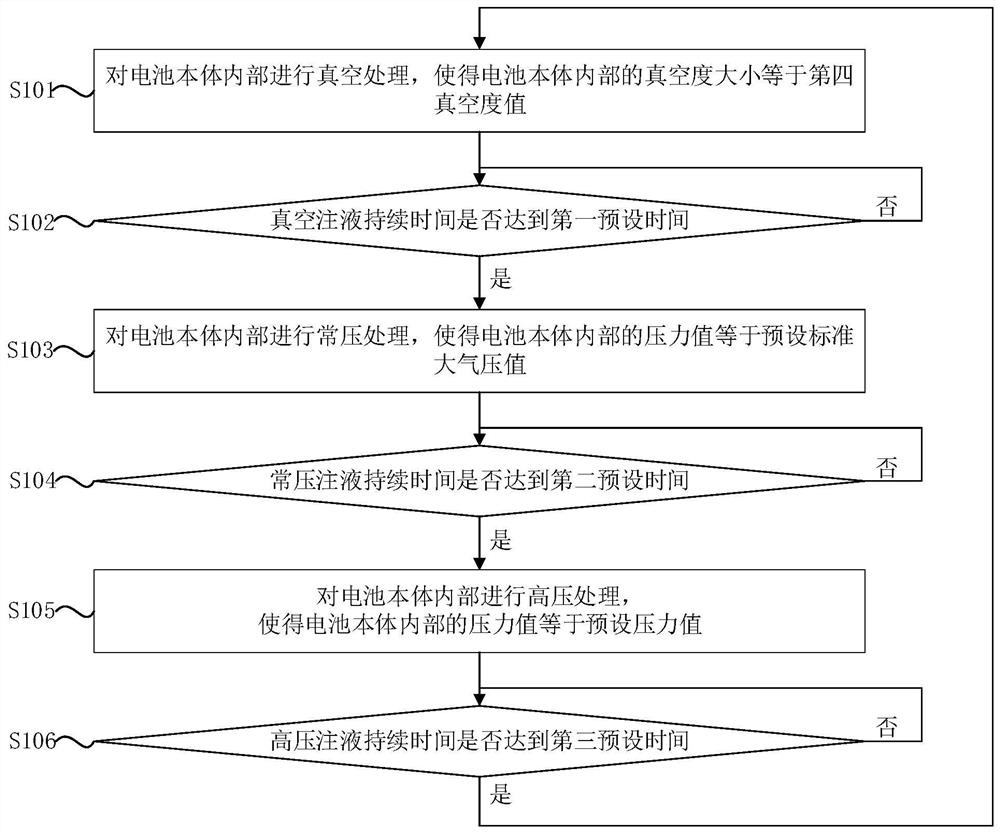

[0038] Step S1: Inject a first predetermined proportion of electrolyte solution into the battery body to obtain a primary liquid-injected battery.

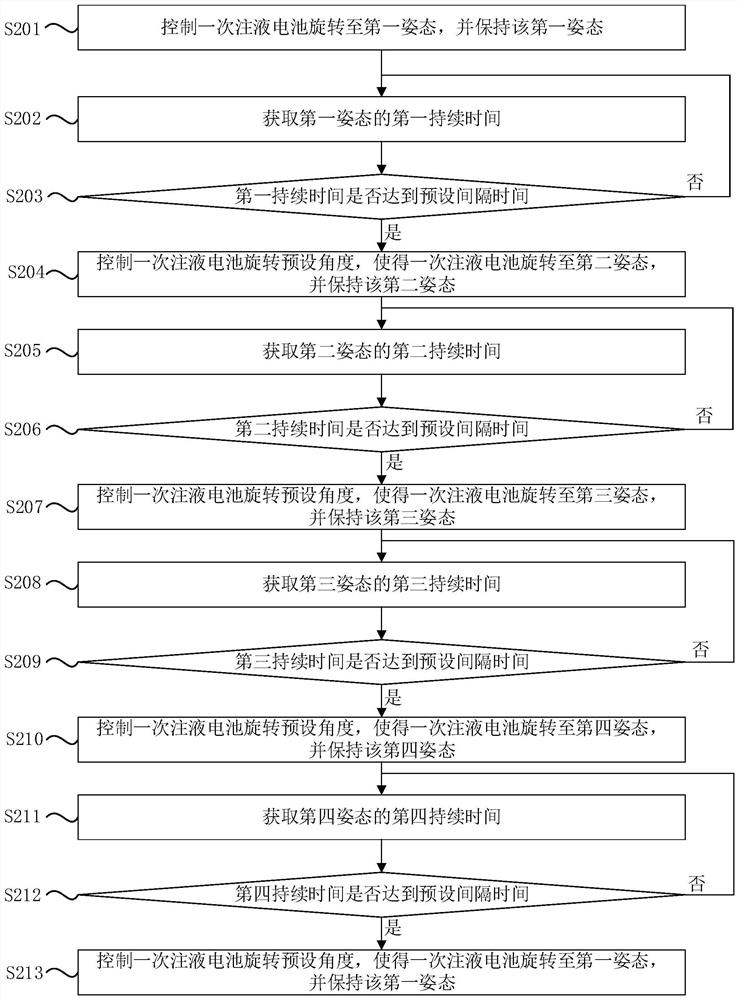

[0039] Step S2: Perform static treatment on the primary liquid-filled battery, and control the rotation of the liquid-filled battery at a preset angle every preset interval during the static process.

[0040] Wherein, the preset interval time ref...

Embodiment 2

[0126] Based on the above-mentioned embodiments, Embodiment 2 of the present invention provides a system for improving the battery interface. This embodiment is applicable to the application scenario of improving the negative electrode sheet lithium or black spots of the lithium battery in the battery manufacturing process. Figure 6 It is a schematic structural diagram of a battery interface improvement system provided in Embodiment 2 of the present invention.

[0127] Such as Figure 6 As shown, the battery interface improvement system 200 includes: a battery body 210, a liquid injection device 220, a pre-charging device 230, and a battery static device 100; the liquid injection device 220 is used to inject a first preset ratio of electrolytic liquid to obtain a primary liquid-injected battery; the battery static device 100 is used for static treatment of the primary liquid-injected battery, and during the static process, the battery static device 100 controls the rotation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com