A negative electrode sheet, preparation method and lithium-ion battery comprising the same

A negative electrode sheet and a negative electrode technology are applied in the field of the negative electrode sheet, the preparation method and the lithium ion battery including the same, to achieve the effects of improving the cycle life, improving the kinetic performance and improving the problem of lithium precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

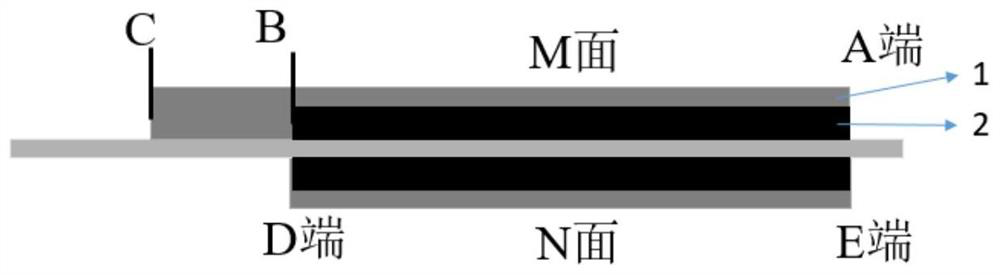

Image

Examples

Embodiment 1

[0066] The first step: prepare the slurry that forms the first negative electrode active material layer: the first negative electrode active material (artificial graphite), the first conductive agent (conductive carbon black) and the first binder (sodium carboxymethyl cellulose) Add it into the stirring tank according to the mass ratio of 94:4.5:1.5, add deionized water to prepare the slurry forming the first negative electrode active material layer, and the solid content of the negative electrode slurry is 40wt%~45wt%;

[0067] The second step: prepare the slurry forming the second negative electrode active material layer: the second negative electrode active material (artificial graphite), the second conductive agent (conductive carbon black) and the second binding agent (sodium carboxymethyl cellulose) According to the mass ratio of 97.5:1:1.5 into the stirring tank, add deionized water to prepare the slurry forming the second negative electrode active material layer, the so...

Embodiment 2-4 and comparative example 1-2

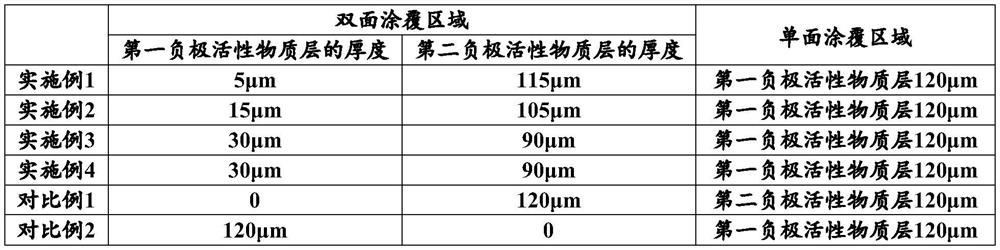

[0074]The other operating steps are the same as in Example 1, the difference is only that the mass percentages of the components in the first negative electrode active material layer and the second negative electrode active material layer are different, as shown in Table 1, and in the single-sided coating area Thickness, the thickness of the first negative electrode active material layer and the second negative electrode active material layer in the double-sided coating area are different, and in comparative example 1, only coat the first negative electrode active material layer (specific structure such as figure 2 shown), in comparative example 2, only the second negative electrode active material layer is coated (the specific structure is as figure 2 shown), as shown in Table 2.

[0075] The mass percentage of active material layer in the negative electrode sheet of table 1 embodiment 1-4 and comparative example 1-2

[0076] The mass percentage content of each...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com