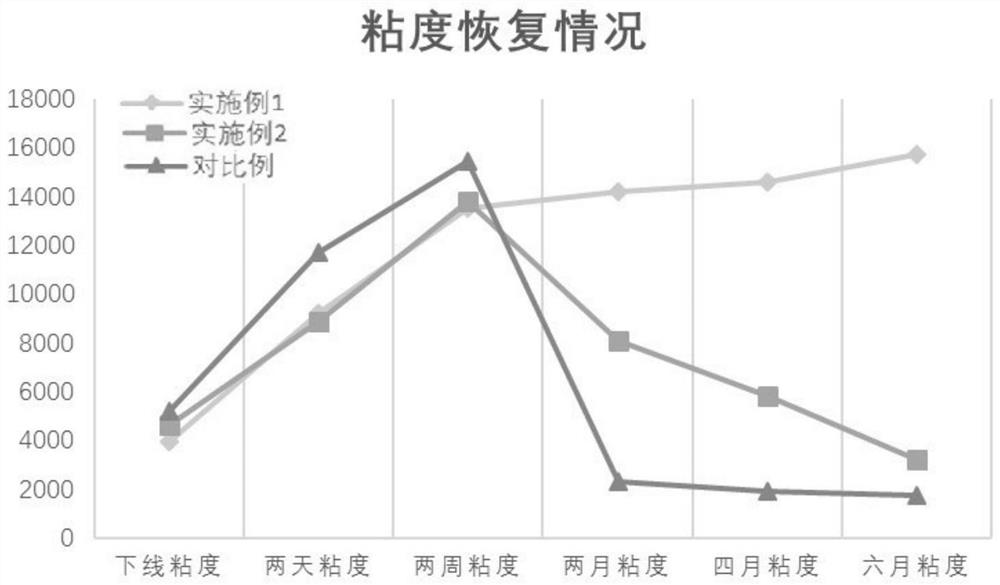

Method for solving problem of thinning of normal-temperature yoghurt in shelf life and yoghurt preparation method

A shelf life and yogurt technology, applied in a method to solve the thinning problem of normal temperature yogurt shelf life and the field of yogurt preparation, can solve the problems of yogurt quality and taste impact, to reduce the degree of thinning and incomplete hydrolysis Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

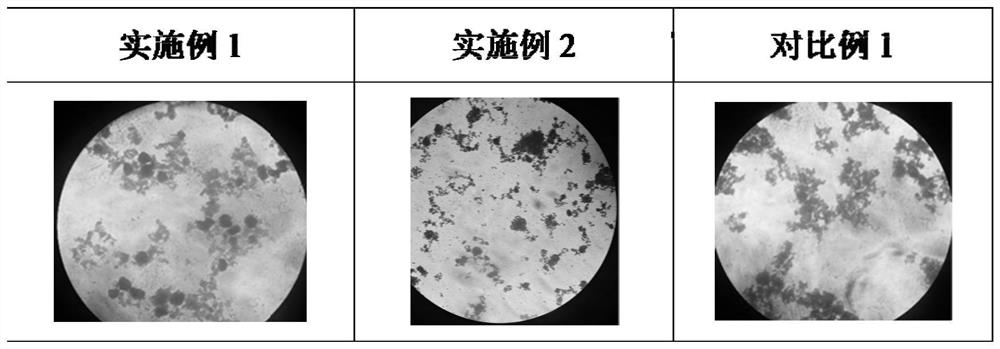

Embodiment 1

[0033] This example provides a method for preparing room temperature yogurt that does not thin out during the shelf life.

[0034] The preparation method provided in this embodiment mainly includes the following steps:

[0035] 1. Preparation of sugar solution: Dissolve white sugar in water at a mass ratio of 1:1, use chemical equipment with mixing, dispersing, shearing, and emulsifying effects for about 15 minutes, and then heat the sugar solution at 132°C Sterilize for 4 seconds, cool to 6-8°C to obtain sugar liquid.

[0036] 2. Preparation of base material: 86 parts of pasteurized milk, 2 parts of modified starch, 2 parts of stabilizer, and 10 parts of sugar solution are weighed based on 100 parts of the total weight of the base material. Heat 50% pasteurized milk (that is, 43 parts of pasteurized milk) to 45°C, add stabilizer, modified starch and sterilized sugar solution, and use chemical equipment with mixing, dispersing, shearing and emulsifying effects at 45°C ℃ for ...

Embodiment 2

[0043] This embodiment provides a kind of preparation method of normal temperature yoghurt, mainly comprises the following steps:

[0044] 1. Preparation of base material: 86 parts of pasteurized milk, 2 parts of modified starch, 2 parts of stabilizer, 5 parts of white granulated sugar and 5 parts of water are weighed based on the total weight of 100 parts of the base material. Heat 50% of raw pasteurized milk (that is, 43 parts of pasteurized milk) to 45°C, add stabilizer, modified starch and white sugar, and use chemical equipment with mixing, dispersing, shearing, and emulsifying effects to melt at 45°C. Feed for about 15 minutes to obtain a uniform and dispersed mixture;

[0045] Then the remaining raw material pasteurized milk (i.e. the remaining 43 parts of pasteurized milk) is squeezed into the above-mentioned mixture and mixed uniformly to obtain the base material, and the base material is homogenized ( That is, adjust the pressure gauge to 20bar first, and then adjus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com