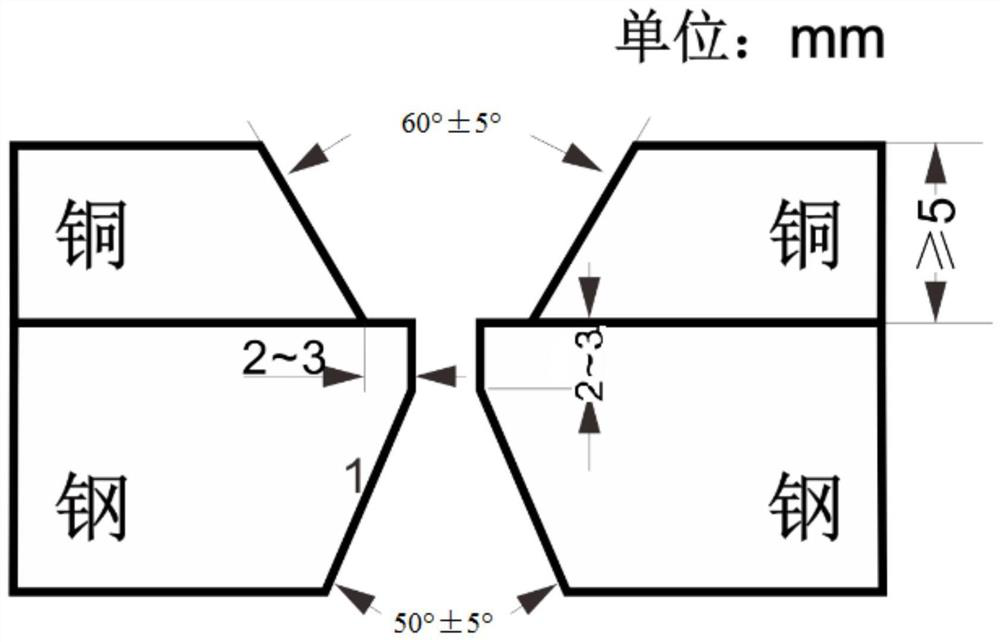

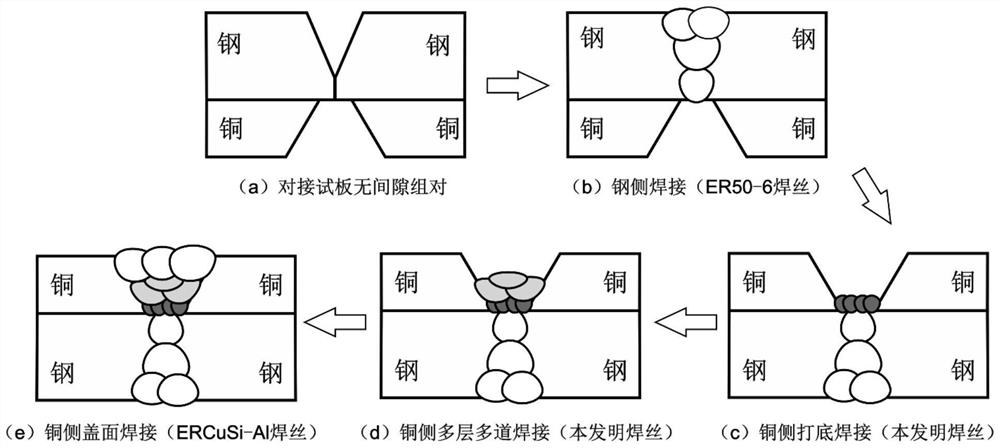

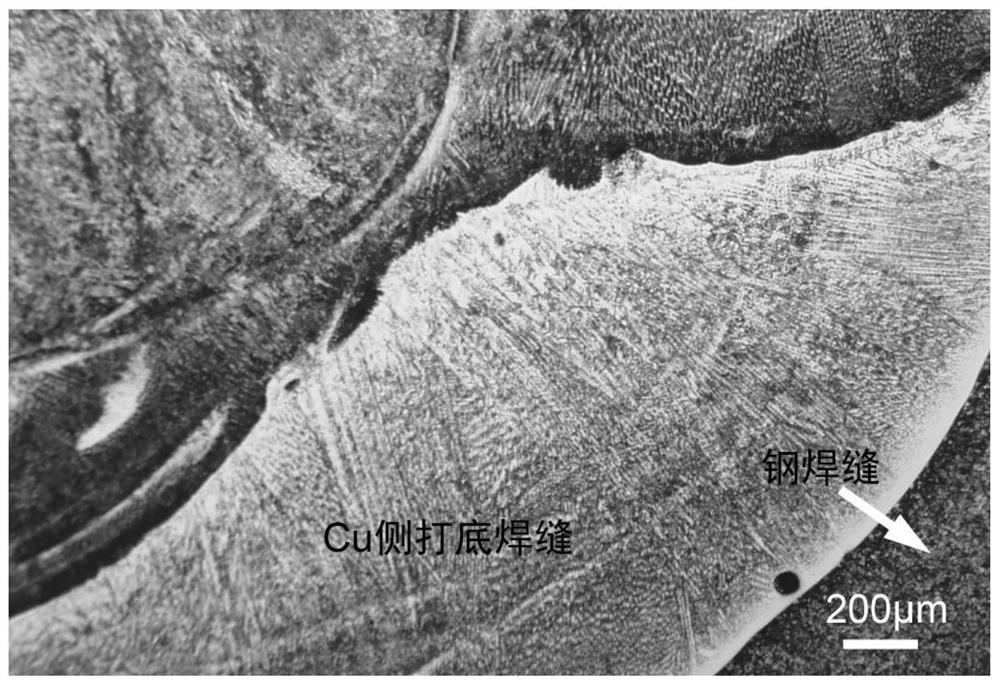

Welding wire for butt welding of thick multi-layer copper-steel composite board and preparation and welding method

A welding method and composite plate technology, applied in welding equipment, welding media, welding accessories, etc., can solve problems such as joint cracking and poor welding seam formation, and achieve the advantages of reducing preheating time, reducing production cost and reducing impact. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present invention also provides a preparation method of welding wire for butt welding of thick clad copper-steel clad plates, the specific steps are as follows:

[0045] Step 1: Take the following medicinal powders by mass percentage: 60-70% of Ni powder, 10-20% of Mn powder, 10-20% of Zn powder, 5-10% of Al powder, the sum of the mass percentages of the above components is 100% ; In step 1, the particle size of each medicinal powder is 200-300 mesh; the purity of the powder is ≥99.90%.

[0046] Step 2: Heat each powder weighed in step 1 in a vacuum heating furnace at a heating temperature of 200-230°C and a holding time of 1-3 hours to remove the crystal water in the powder; place the dried powder in a mixing powder Fully mix in the machine, the mixing time is 1~3h;

[0047] Step 3: Use pure copper strip as the solder skin, use alcohol to remove the grease on the surface of the pure copper strip, and wrap the powder prepared in step 2 in the pure copper strip thro...

Embodiment 1

[0053] Step 1: take by weight the following powders respectively by mass percentage: Ni powder 60%, Mn powder 10%, Zn powder 20%, Al powder 10%, the sum of above component mass percentage is 100%; In step 1, each powder The particle size is 200 mesh; the purity of the powder is ≥99.90%.

[0054] Step 2: Put the powder weighed in step 1 into a vacuum heating furnace for heating at a temperature of 200°C and a holding time of 1 hour to remove the crystal water in the powder; place the dried powder in a powder mixer Carry out sufficient mixing, the mixing time is 1h;

[0055] Step 3: Use pure copper strip as the solder skin, use alcohol to remove the grease on the surface of the pure copper strip, and wrap the powder prepared in step 2 in the pure copper strip through the flux-cored wire drawing equipment. The first drawing die has an aperture of 2.6 mm; in step 3, the pure copper strip has a thickness of 0.3mm and a width of 7mm, and the filling amount of the flux core powder i...

Embodiment 2

[0061] Step 1: take by weight the following medicated powders respectively by mass percentage: Ni powder 70%, Mn powder 15%, Zn powder 10%, Al powder 5%, the sum of above component mass percentages is 100%; In step 1, each medicated powder The particle size is 300 mesh; the purity of the powder is ≥99.90%.

[0062] Step 2: Put the powder weighed in step 1 into a vacuum heating furnace for heating at a temperature of 230°C and a holding time of 3 hours to remove the crystal water in the powder; place the dried powder in a powder mixer Carry out sufficient mixing, the mixing time is 3h;

[0063] Step 3: Use pure copper strip as the solder skin, use alcohol to remove the grease on the surface of the pure copper strip, and wrap the powder prepared in step 2 in the pure copper strip through the flux-cored wire drawing equipment. The first drawing die has an aperture of 2.6 mm; in step 3, the pure copper strip has a thickness of 0.3mm and a width of 7mm, and the filling amount of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com