In-hole grinding device for electric heating element casing of voltage stabilizer

A technology of electric heating elements and voltage regulators, which is applied in the direction of grinding drive devices, grinding machines, metal processing equipment, etc., can solve the problems that grinding equipment cannot be realized, and achieve the effect of simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

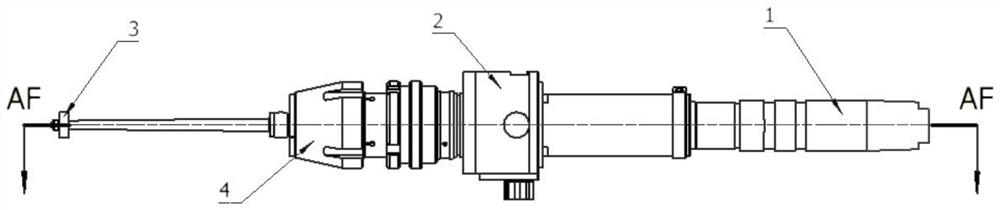

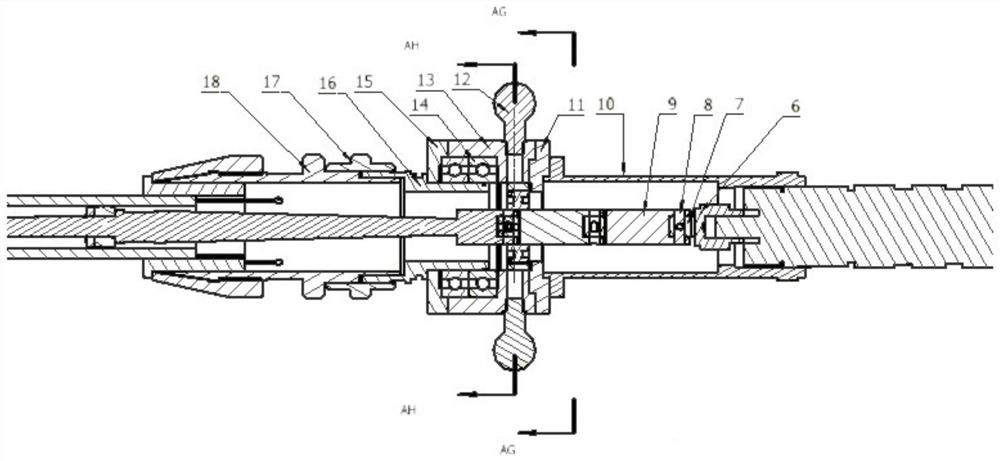

[0039] like Figure 1 to Figure 7 As shown, the grinding device in the casing hole of the electric heating element of the voltage stabilizer includes a power assembly 1, a grinding head 29 connected with the power assembly 1 through the transmission assembly 2, a device frame as a bearing base, and also includes a grinding head 29 for adjusting the grinding head 29. Position alignment assembly, the transmission assembly 2 includes a transmission shaft 28, the grinding head 29 is mounted on the transmission shaft 28, and the alignment assembly includes a rolling bearing, a rotating body 13, and an eccentric adjustment slider 22;

[0040] The rotating body 13 is installed on the device frame and the rotating body 13 can rotate around its own axis;

[0041] The transmission shaft 28 is mounted on the eccentric adjustment slider 22 through a rolling bearing, and the eccentric adjustment slider 22 is slidably connected to the rotating body 13, and the sliding direction of the slidi...

Embodiment 2

[0048] This embodiment is further limited on the basis of Embodiment 1. As a technical solution in which the radial position of the grinding head 29 is continuously adjustable and the adjustment accuracy is high, it is provided as follows: it further includes the eccentric adjustment slider 22 and the rotating body 13. The feed screw 24 between them is used to drive the eccentric adjustment slider 22 to slide relative to the rotary body 13 in the radial direction of the rotary body 13 . For specific applications, a chute can be provided on the rotating body 13, and the groove wall of the chute can be used to provide an anti-rotation constraint for the eccentric adjustment slider 22, so that the eccentric adjustment slider can be driven during the process of rotating the feed screw 24. 22 slides along the axis direction of the feed screw 24 .

[0049] As mentioned above, for the specific application of this device, such as for the treatment of excess height, the overall excess ...

Embodiment 3

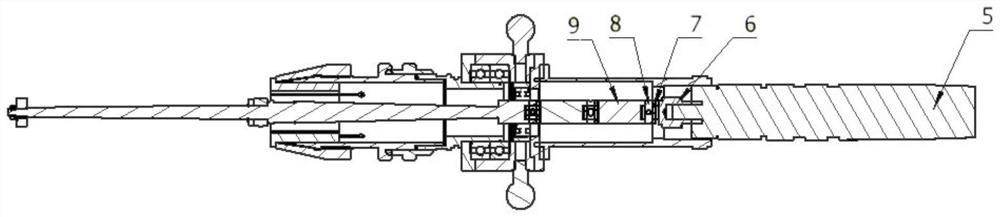

[0051] This embodiment is further limited on the basis of the technical solution provided in Embodiment 1. In the prior art, in order to adapt to the radial position adjustment of the eccentric adjustment slider 22, the corresponding reversing transmission member may include, for example, a flexible shaft, a universal joint 9 etc., as a technical solution that can reduce the vibration of the device during processing to facilitate the processing quality, it is set as follows: the reversing transmission member includes a universal joint 9, and the universal joint 9 serves as the transmission shaft 28 and the power Transmission connection between components 1.

[0052] In order to match the parallelism of the axes of the transmission shaft 28 and the power assembly 1, for example, after the relative positions of the power assembly 1 and the sleeve 27 are fixed, the adjustment of the radial position of the grinding head 29 does not affect the relationship between the sleeve 27 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com