Manufacturing method of plastic product

A manufacturing method and technology of products, applied in the direction of manufacturing tools, additive manufacturing, metal processing equipment, etc., can solve the problems of monotonous products, rigid appearance, and difficulty in meeting the individual requirements of consumers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be specifically and further described below in conjunction with the accompanying drawings. A method of manufacturing plastic products, characterized in that: comprising the following steps:

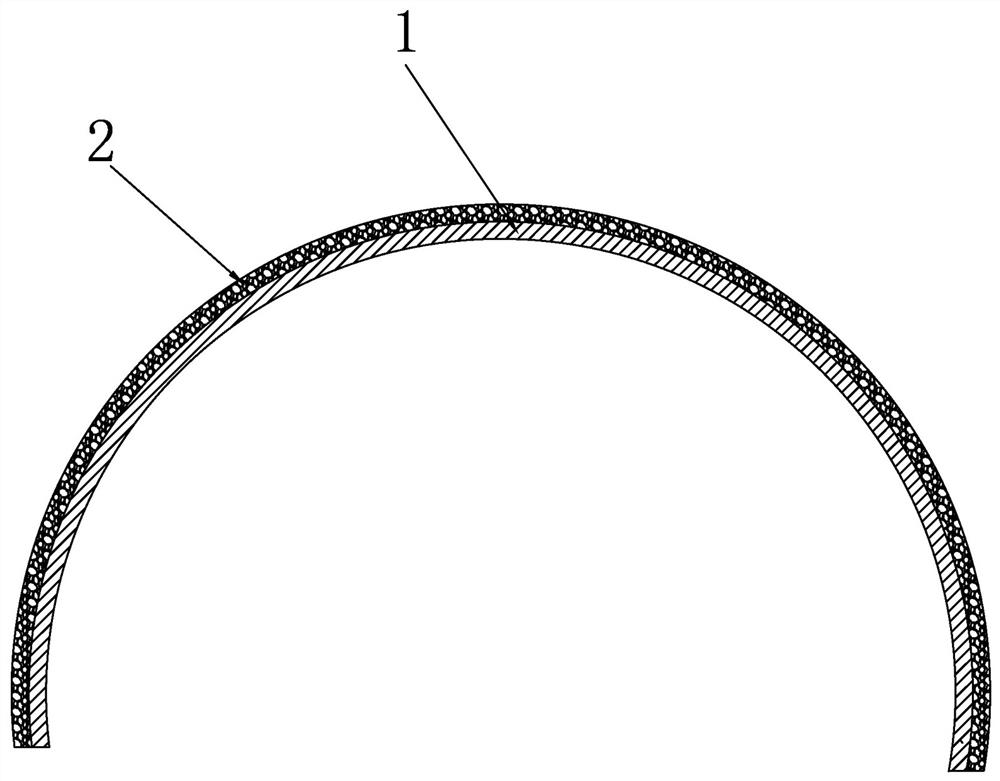

[0016] A: Make a base mold 1 similar in shape to the finished product;

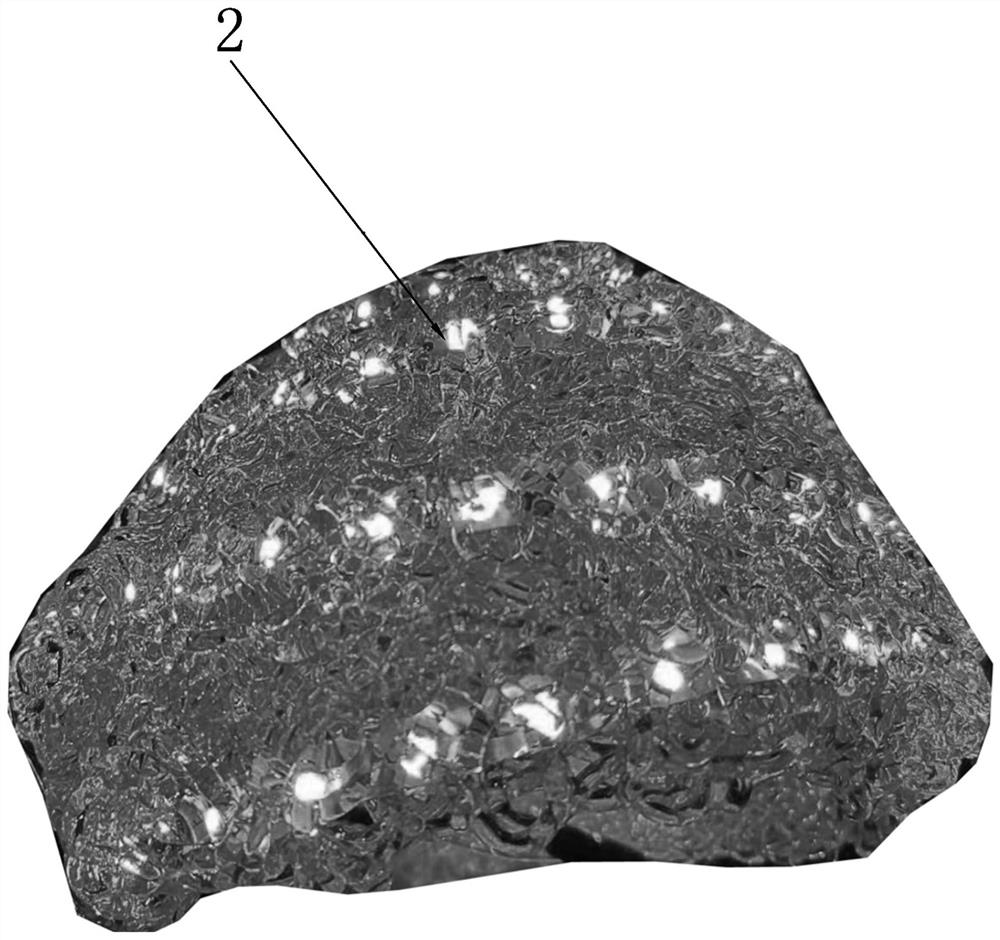

[0017] B: On the surface of the bottom mold 1, the skeleton layer 2 is formed by spraying the plastic spinning process, and the material of the skeleton layer 2 is required to be light-transmitting or reflective plastic;

[0018] C: Release the mold after the skeleton layer 2 is cooled and solidified.

[0019] In the plastic spinning process, the cross-section of the sprayed plastic filaments is circular.

[0020] In the plastic spinning process, the cross-section of the sprayed plastic filaments is oval.

[0021] In the plastic spinning process, the cross-section of the sprayed plastic filaments has an irregular shape.

[0022] The skeleton layer can be arranged in one layer or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com