Production method of Al-Cu-Mg-Fe-Ni-series aluminum alloy extruded material

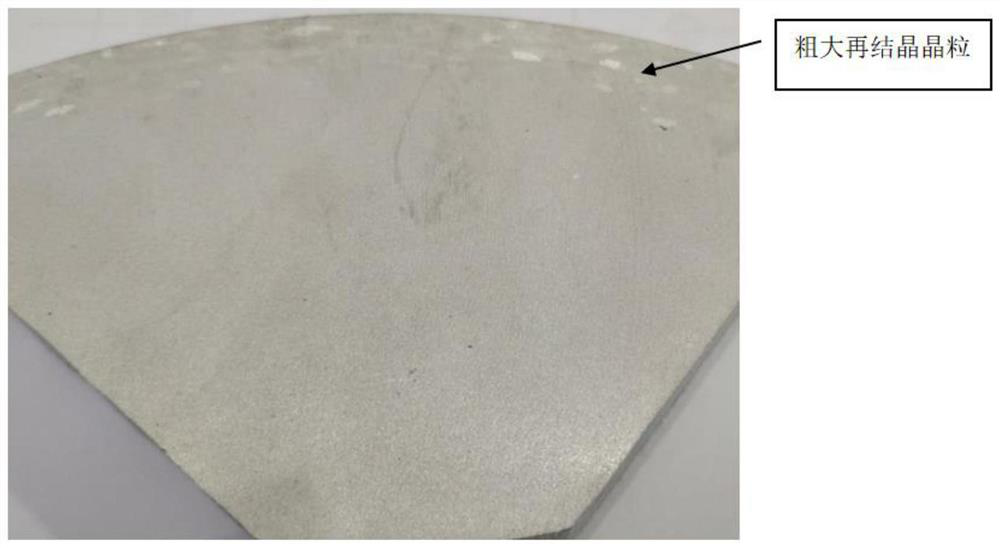

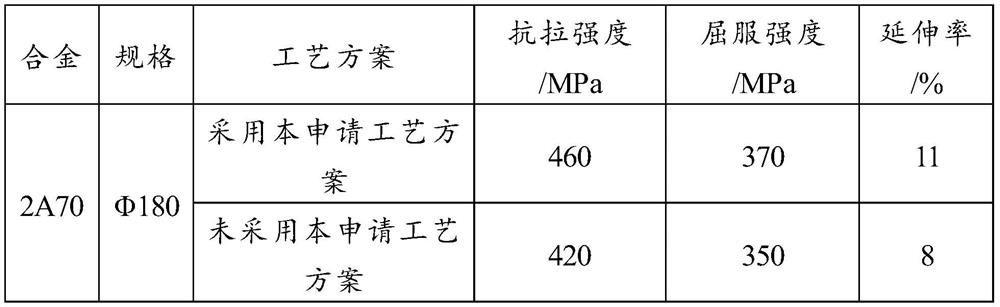

An al-cu-mg-fe-ni, 1. al-cu-mg-fe-ni technology is applied in the production field of Al-Cu-Mg-Fe-Ni series aluminum alloy extrusion materials, and can solve the problem of crystal Uneven particle size, coarse extrusion material, unsatisfactory effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) Ingot solution treatment: 2A70 aluminum alloy ingot with a diameter of 300mm was solution treated at 520°C for 15 hours;

[0030] 2) Ingot quenching: Quenching the aluminum alloy ingot after solid solution treatment in water at 60-80°C;

[0031] 3) Ingot heating: heating the quenched ingot to 400°C;

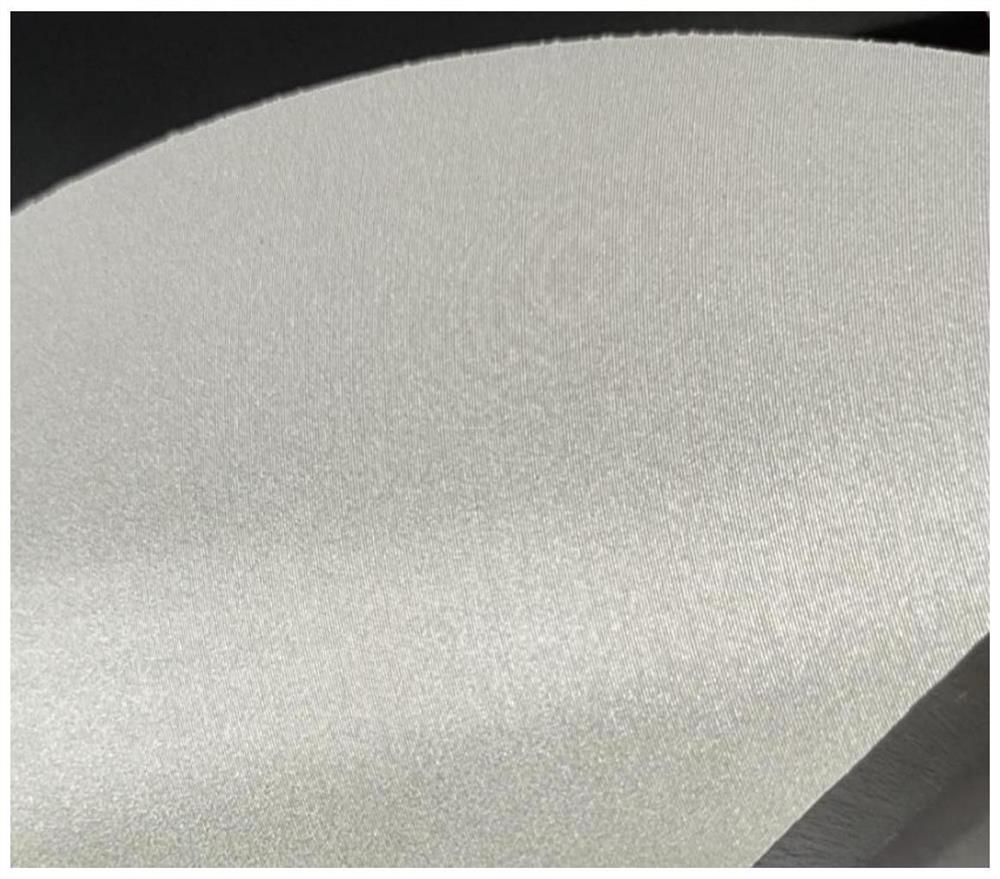

[0032] 4) Extrusion: Extrude the heated ingot, the temperature of the extruding cylinder is 430-450°C, and the extrusion speed is ≤0.2m / min. figure 1 A low-magnification photograph of the aluminum alloy ingot prepared for this example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com