Method for improving steam pump rotating speed regulation based on chopper control

A control method and steam pump technology, applied in pump control, non-variable pumps, machines/engines, etc., can solve the problem that the PID regulation loop cannot effectively suppress fluctuations, and achieve the effect of suppressing the disturbance of the steam pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

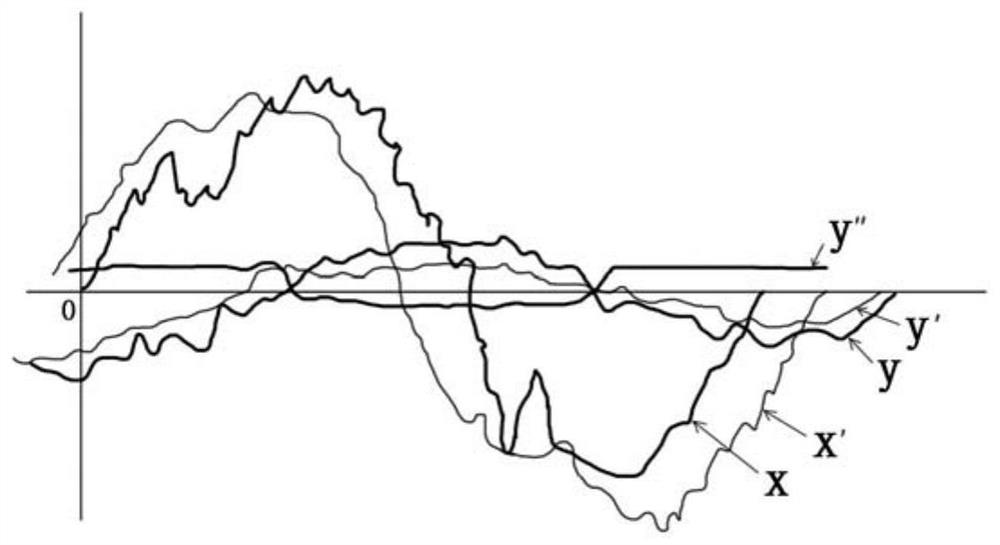

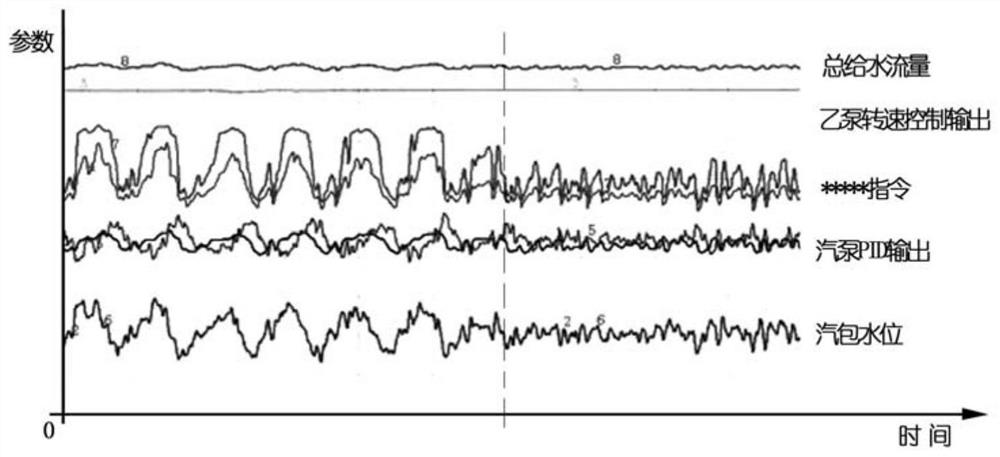

[0017] Under the stable working condition of a single steam source output, the moment the newly input steam source intervenes to do work, the high pressure will cause the sudden increase in the speed of the steam turbine, and the system cannot digest the sudden increase in pressure, causing system disturbance. The disturbance is due to the increase of the system load, and the steam pump needs a higher-pressure air source to maintain the load, resulting in an uncertain time point when the new high-pressure air source (main steam, 14MPa) and the original low-pressure air source (auxiliary steam and Four-stage steam extraction, 1-3MPa) overlapping, the original automatic control logic of the system cannot effectively overcome the energy disturbance, resulting in periodic oscillation of the regulated system or even the divergence of the regulated quantity, which eventually leads to the shutdown of the steam pump. If the divergence of the regulated quantity is not timely control, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com