Filter screen mounting assembly and air conditioner

A technology for installing components and filter screens, applied in the field of air conditioners, can solve the problems of high disassembly difficulty, difficult disassembly and assembly of filter screens, damage to filter screens, etc., and achieves the effects of low disassembly difficulty, high disassembly and assembly efficiency, and firm installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

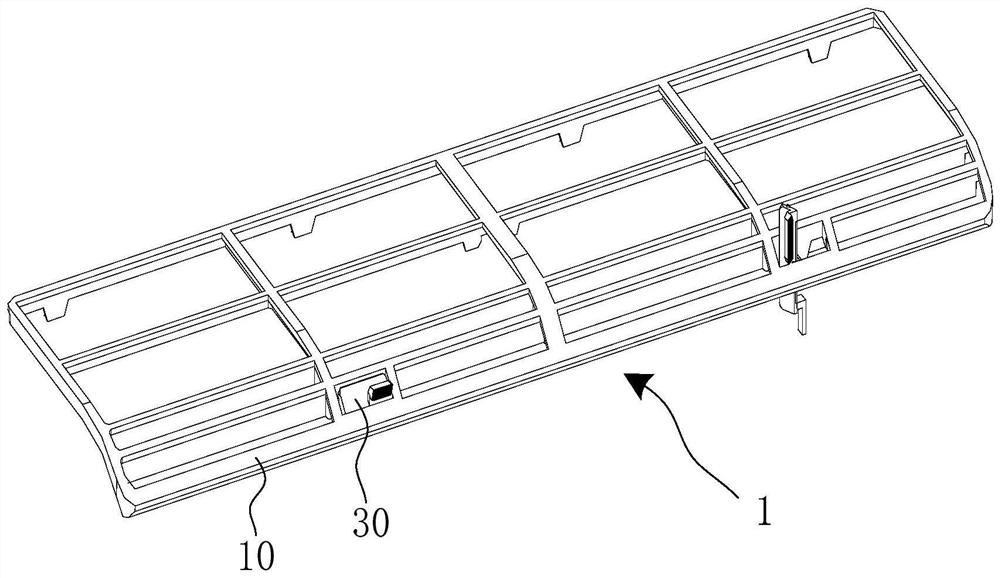

[0051] Such as figure 1 As shown, this embodiment provides a filter installation assembly 1, including a filter 10 and a locking member 30; the locking member 30 includes: a locking part and a dismounting part; when the locking part 30 rotates, the locking part realizes locking or unlocking, To disassemble the filter screen 10.

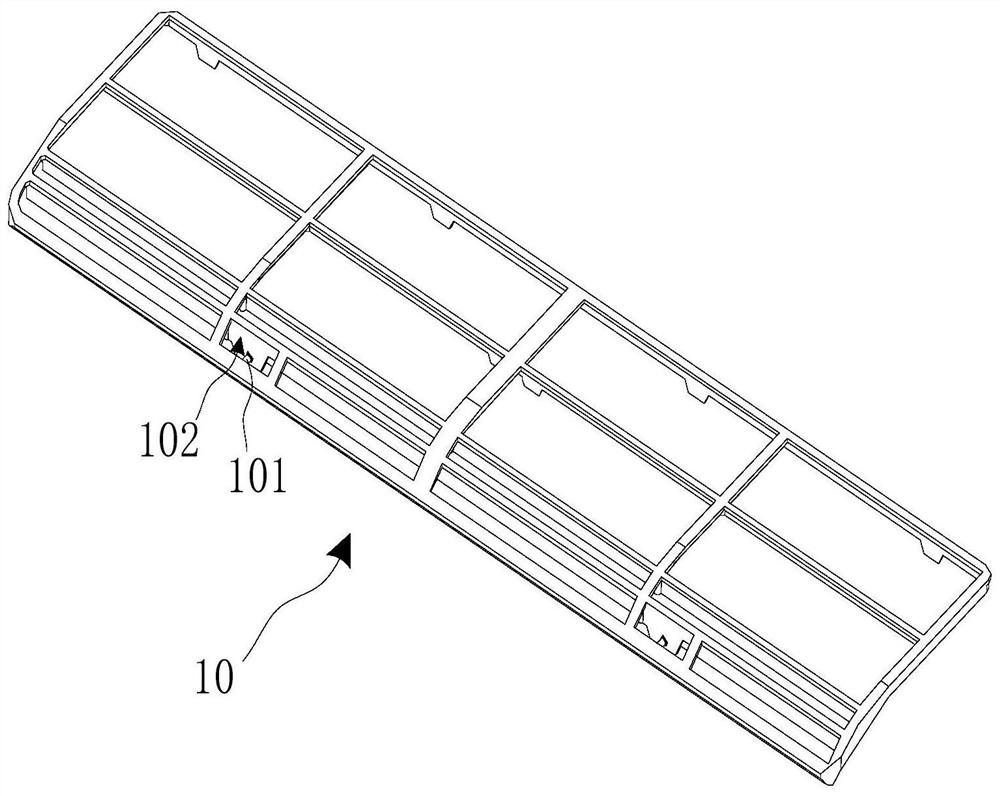

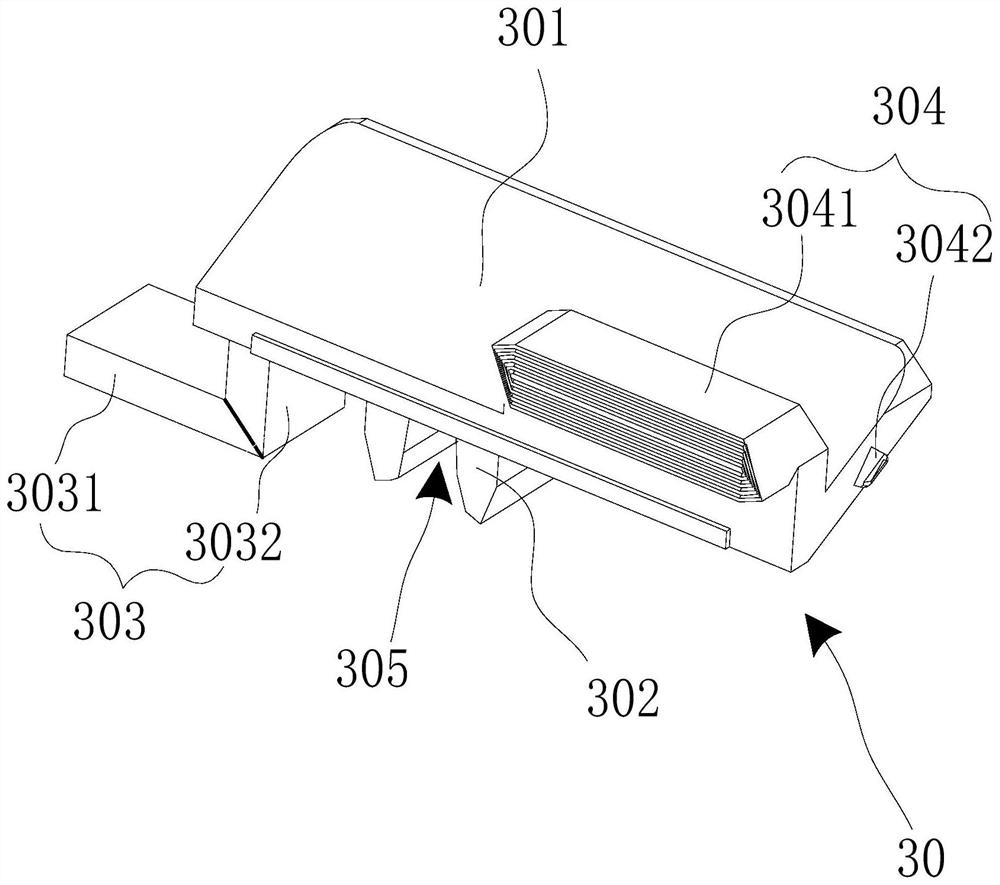

[0052] Specifically, such as figure 2 As shown, the filter screen 10 is provided with at least one locking member installation area 102, and the locking member installation area 102 is provided with a rotating shaft 101; as image 3 and Figure 4 As shown, the locking part is the locking end 303, and the dismounting part is the lifting end 304; the locking member 30 also includes: a body 301; There is also a rotating part 302 between them, and the rotating part 302 is arranged on the body 301; the rotating part 302 is provided with a shaft hole 305, and the shaft hole 305 is connected with the rotating shaft 101; the locking member 30 can rotate r...

Embodiment 2

[0056] Such as image 3 As shown, the locking end 303 extends downwards and bends away from the rotating portion 302 .

[0057] Specifically, the locking end 303 includes a locking block 3031 and an extension block 3032, one end of the extension block 3032 is connected to the lower surface of the body 301, and the other end is connected to the locking block 3031; the connection between the locking block 3031 and the extension block 3032 forms a certain angle of bending, and It is bent toward the side away from the rotating part 302 . The connection between the locking block 3031 and the extension block 3032 is set in a bent shape, which is convenient for the locking block 3031 to be locked, so that the filter screen 10 is not easy to slip off after installation.

[0058] Such as image 3 As shown, the lift end 304 includes: a handle portion 3041 and a filter net buckle end 3042 .

[0059] Specifically, the handle part 3041 is arranged on both sides of the rotating part 302 ...

Embodiment 3

[0061] Such as Figure 4 As shown, the locking end extends downwards and bends away from the rotating portion 302 .

[0062] Specifically, the locking end includes a locking block 3031 , one end of the locking block 3031 is connected to the lower surface of the body 301 , and the other end is bent in a groove shape toward a side away from the rotating part 302 . The connection between the locking block 3031 and the extension block 3032 is set in a curved shape, which is convenient for the locking block 3031 to be locked, so that the filter screen 10 is not easy to slip off after installation.

[0063] Such as Figure 4 As shown, the handle part 3041 and the rotating part 302 are located on the same side of the body 301, and are arranged on both sides of the rotating part 302 opposite to the locking block 3031. The handle part 3041 is connected to the body 301 through the connector 306; the handle part 3041 A first card slot (not shown in the figure) is provided at the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com