Sensor wireless calibration device and method

A calibration device and sensor technology, applied in the field of sensor calibration, can solve problems such as complicated line connections and limited range of activities for operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

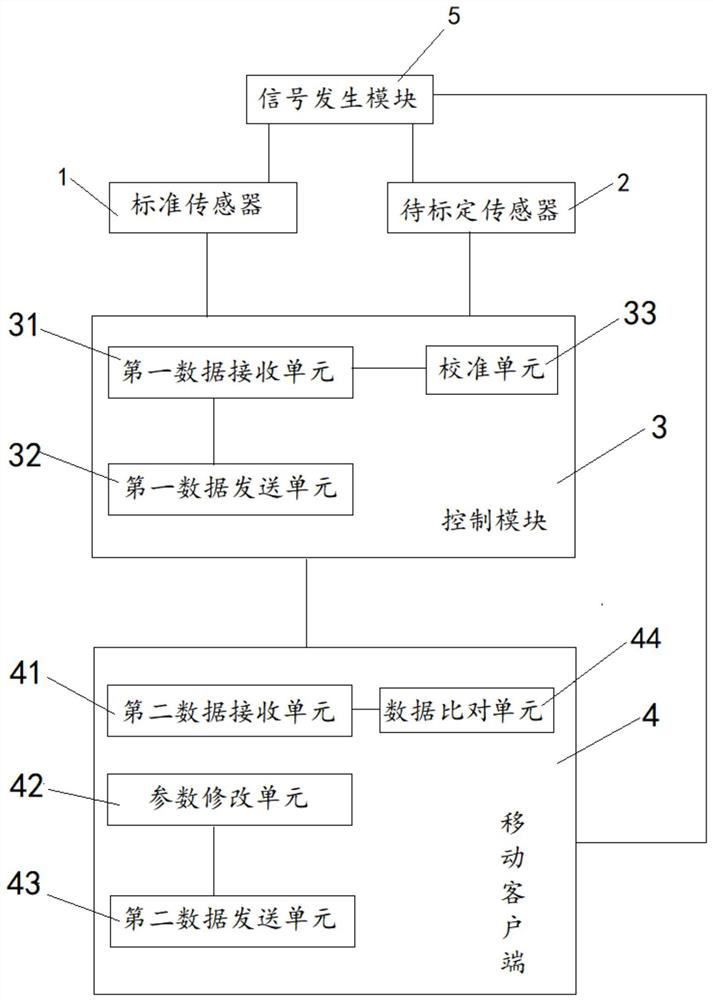

[0033] The embodiment of the present invention provides a sensor wireless calibration device, please refer to the attached figure 1 , the device includes:

[0034] standard sensor 1;

[0035] The sensor 2 to be calibrated, the sensor 2 to be calibrated is the same type of sensor as the standard sensor 1, and the measurement accuracy of the standard sensor 1 is higher than that of the sensor 2 to be calibrated;

[0036] Specifically, the sensor to be calibrated 2 and the standard sensor 1 are sensors of the same type, that is, the sensor to be calibrated 2 and the standard sensor 1 are pressure sensors, temperature sensors, flow sensors, and the like. The measurement accuracy of the standard sensor 1 is higher than that of the sensor 2 to be calibrated, so that the output value of the standard sensor 1 can be used as a standard for measuring the accuracy of the sensor 2 to be calibrated.

[0037] For ease of description, the embodiment of the present application takes a press...

Embodiment 2

[0071] The embodiment of the present invention also provides a sensor wireless calibration method, using the sensor wireless calibration device, please refer to the attached figure 1 , the method includes:

[0072] Step S1: obtaining a third parameter;

[0073] Step S2: controlling the signal generation module 5 to output a test signal according to the third parameter;

[0074] Step S3: applying the test signal to the standard sensor 1 and the sensor to be calibrated 2;

[0075] Step S4: collecting the first output signal and the second output signal;

[0076] Step S5: comparing the first output signal and the second output signal to obtain a comparison result;

[0077] Step S6: judging whether the comparison result is within a predetermined error range;

[0078] If it is, then the sensor 2 to be calibrated is qualified, no calibration is required, and the calibration ends;

[0079] If not, obtain the first modification parameter and the second modification parameter, obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com