Metal pipe airtightness tester

A technology for air tightness testing and metal pipes, which is applied in the direction of fluid tightness testing, liquid tightness measurement using liquid/vacuum degree, machine/structural component testing, etc. It can solve the problems affecting the efficiency and speed of air tightness testing Slow, low efficiency and other problems, to achieve the effect of improving production testing efficiency, avoiding loud noises, and shortening testing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

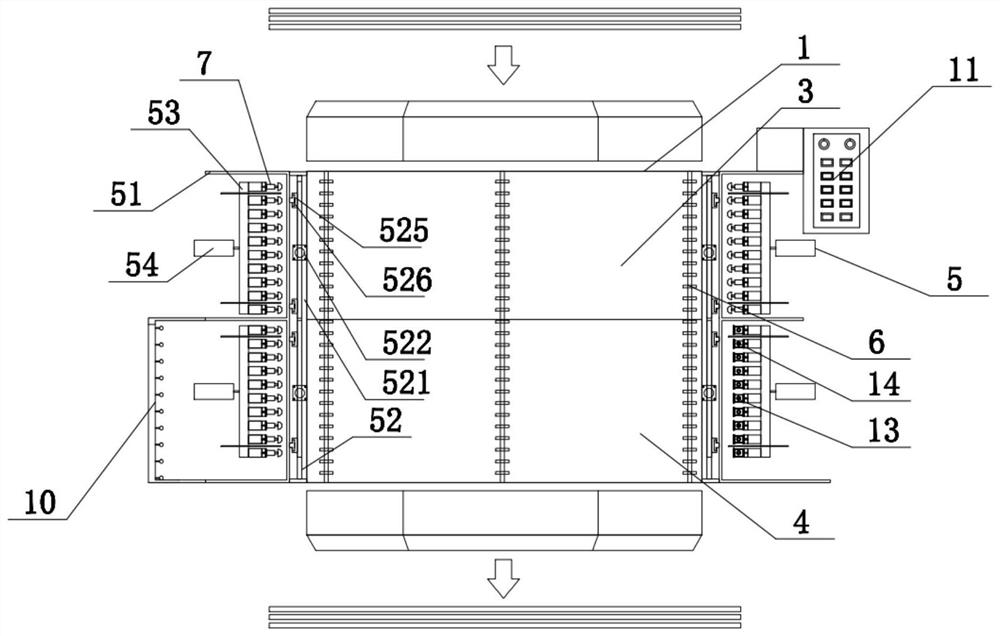

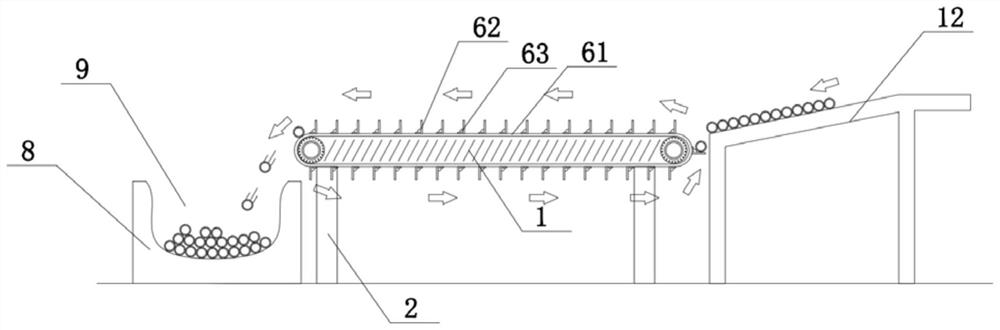

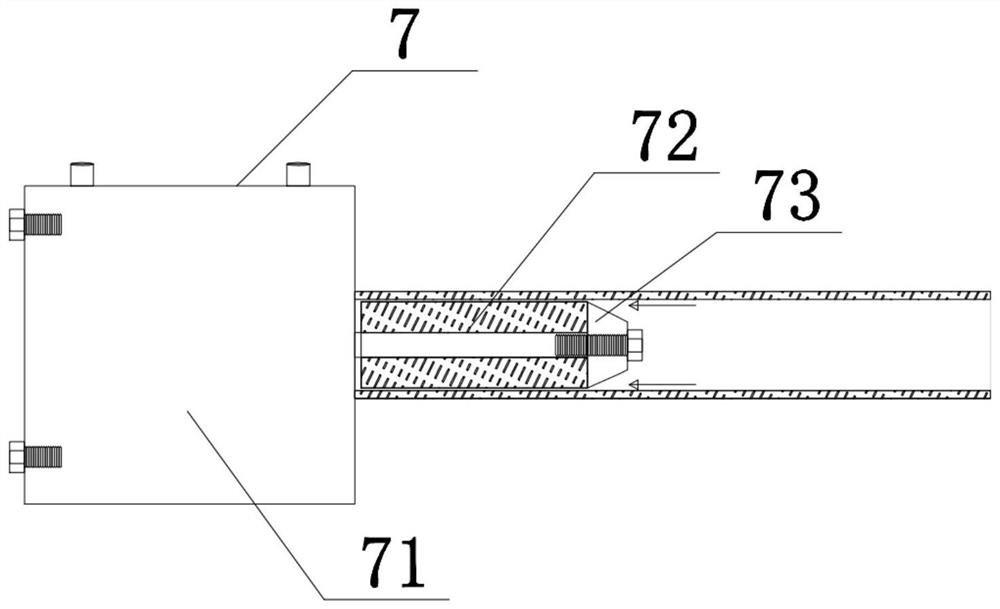

[0031]Please refer to Figures 1-4, a metal pipe airtightness tester, including a workbench 1, a support frame 2 is fixedly installed at the bottom of the workbench 1, and a high-pressure detection area 3 is provided on the front side of the workbench 1 , the front of the workbench 1 is provided with a low-voltage detection area 4 relative to the other side of the high-voltage detection area 3, and both sides of the high-voltage detection area 3 and the low-voltage detection area 4 are fixedly installed with a drive mechanism 5, and the low-voltage detection area 4 The end of the driving mechanism 5 on one side is fixedly equipped with a sealed pressurized sleeve 13, and the upper end of the sealed pressurized sleeve 13 is provided with a pressurized port 14, the two sides of the high-pressure detection area 3 and the other side of the low-pressure detection area 4 The end of the driving mechanism 5 is fixedly installed with sealing assemblies 7 at equal intervals. As a specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com