MEMS scanning mirror and laser projector

A technology for scanning mirrors and mirrors, which is applied in the field of laser projection, can solve the problems of the mirror 10 being hindered in rotation and difficult to accurately drive the mirror 10, and achieve the effects of miniaturization, precision improvement, and driving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

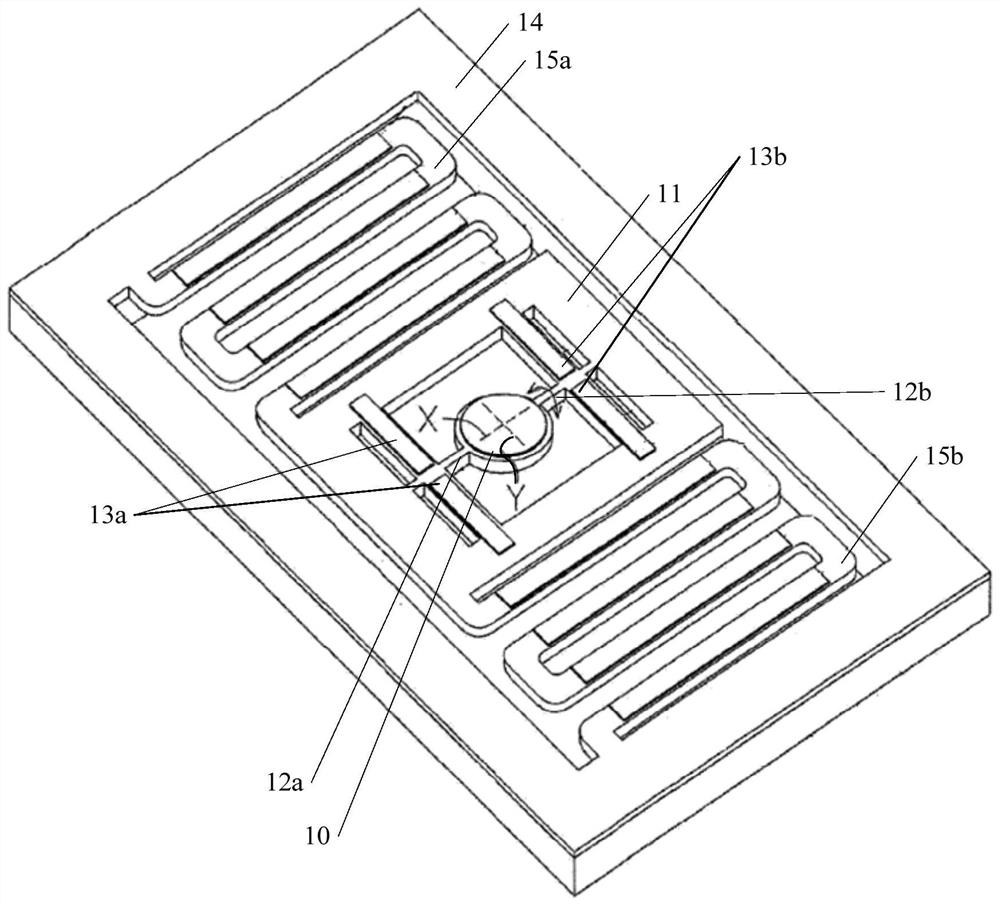

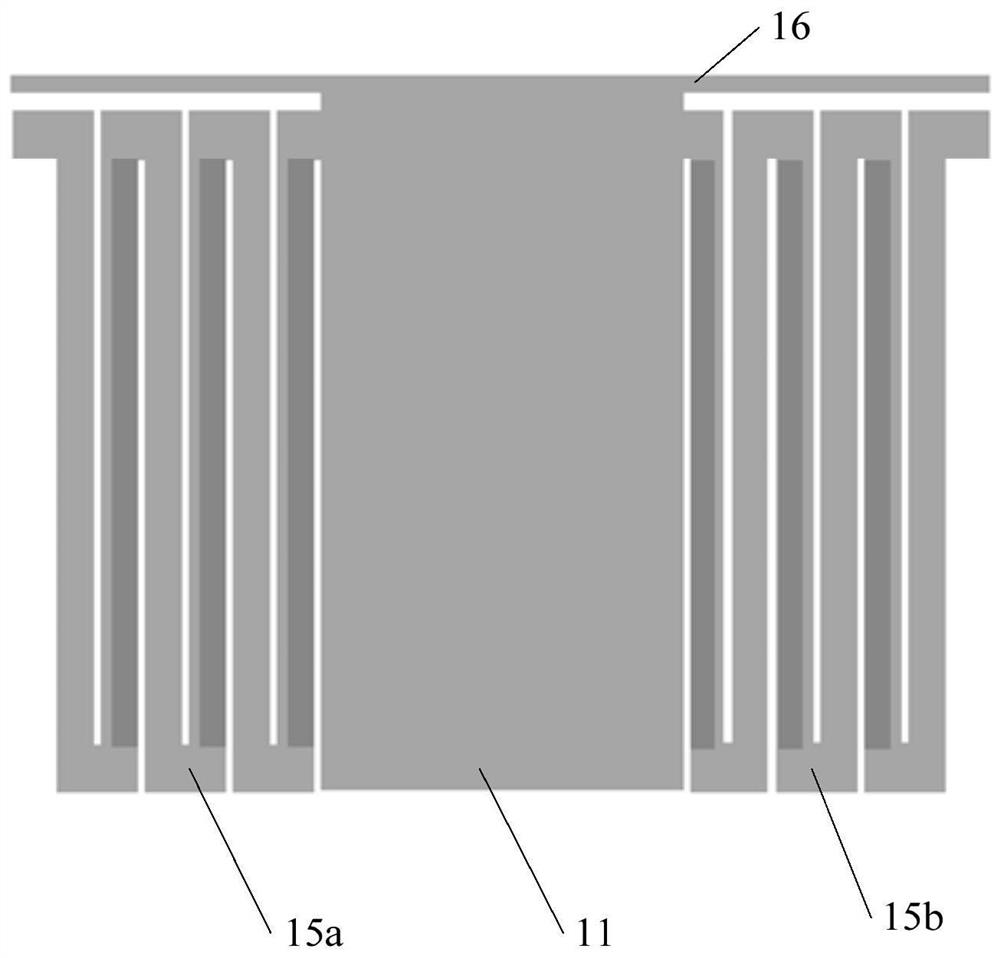

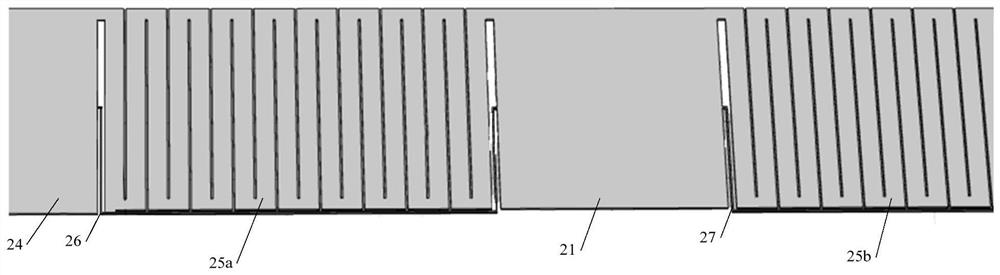

[0027] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. Similar parts in the figures are denoted by the same reference numerals. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

[0028] One embodiment of the present invention provides a MEMS scanning mirror, including a support, a mirror, and a first piezoelectric actuator and a second piezoelectric actuator respectively used as a cantilever, the first piezoelectric actuator The device and the second piezoelectric actuator are used to rotate the mirror around the first rotation axis, and the MEMS scanning mirror also includes a first sensing beam, one end of the first sensing beam is connected to the support, and the other end Connecting to one sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com