Auxiliary device of die head threading machine

An auxiliary device and threading machine technology, applied in the direction of thread cutting device, thread cutting machine, metal processing equipment, etc., can solve the problems that the work efficiency is easily affected by the state of the operator, the operator has no way, waste of time and manpower, etc., to ensure The effect of threading quality, reducing labor consumption and reducing time waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be clearly and completely described below in conjunction with the embodiments.

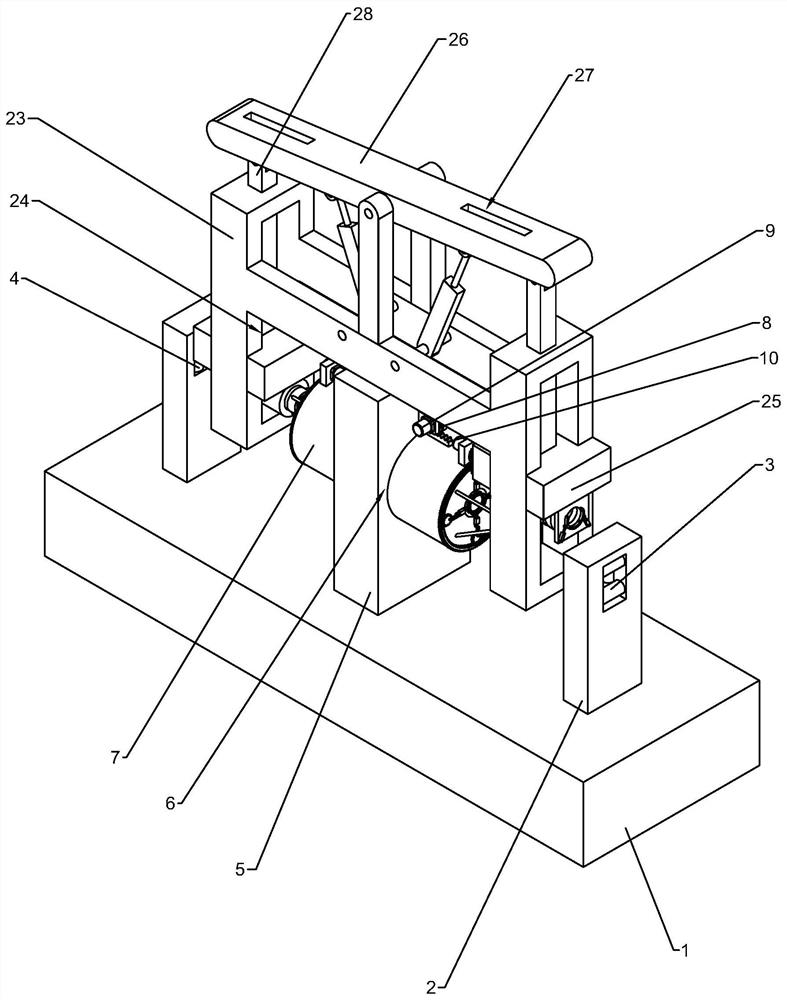

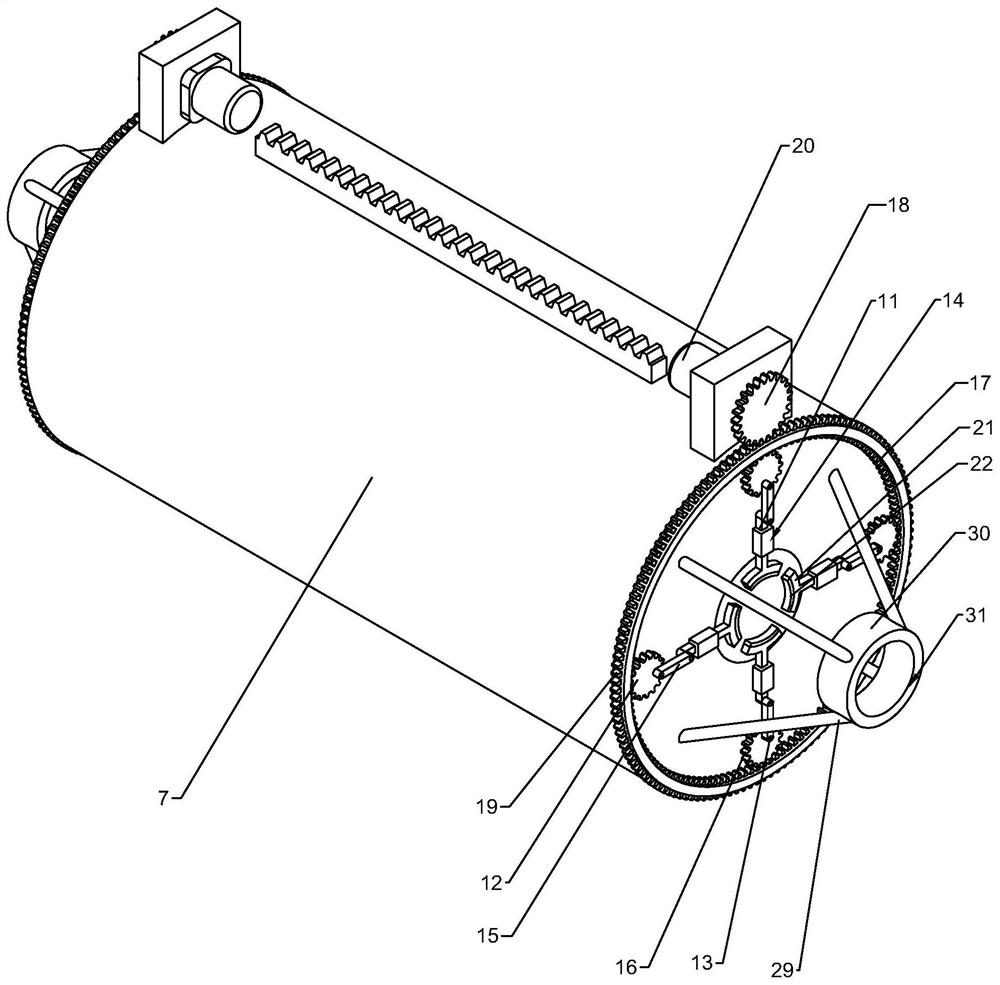

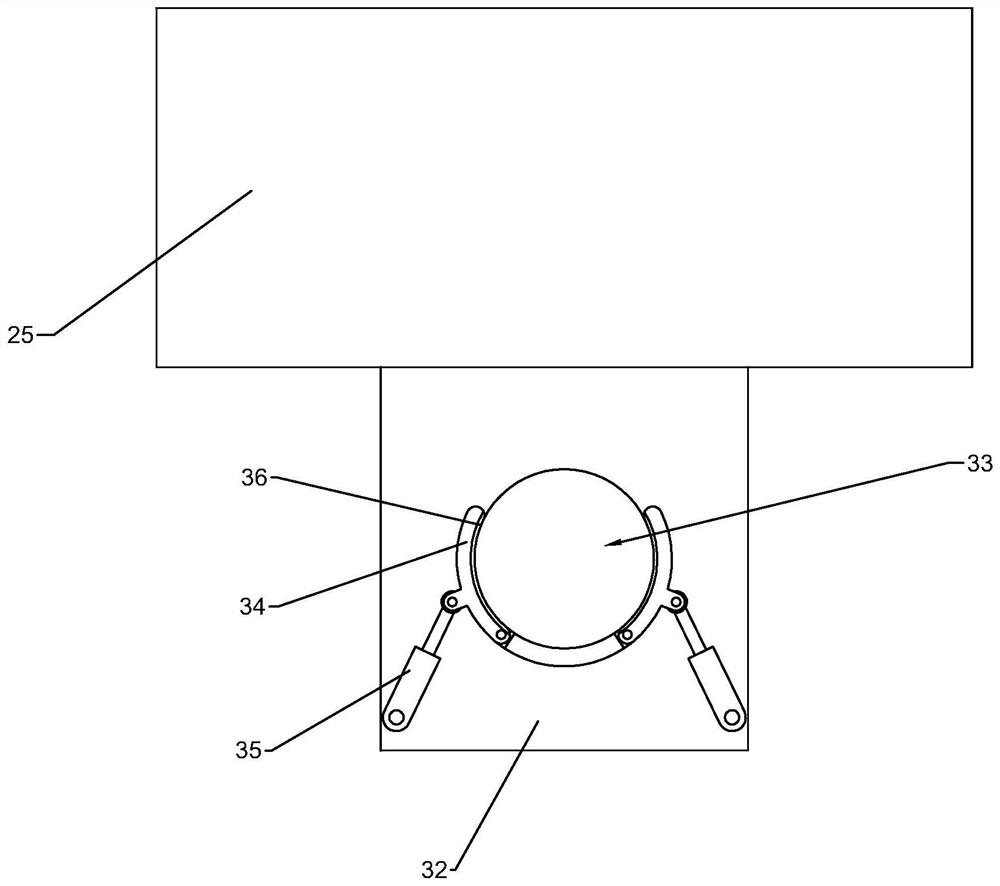

[0034] See attached figure 1 , an auxiliary device for a threading machine, comprising an operating table 1, the operating table 1 has a rectangular structure, both sides of the operating table 1 are fixed with limit brackets 2, and both limit brackets 2 are provided with a number of limit rollers 3 for rotation. Positioning rollers 3 are distributed in a staggered manner, and a number of vertical rollers 4 are rotated in the positioning bracket 2, and the axial direction of the vertical rollers 4 is perpendicular to the upper surface of the operating table 1.

[0035]A support frame 5 is fixed on the console 1, and the support frame 5 has a T-shaped structure. A control hole 6 is opened through the support frame 5, and a console 7 is provided for sliding in the control hole 6. Gear 8, a traverse motor 9 is fixed on one side of the support frame 5, the output sha...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap