Golf club head welding method

A golf club head and welding method technology, applied in golf balls, golf clubs, welding equipment and other directions, can solve the problems of different product quality, time-consuming and labor costs, avoid relative displacement, save labor costs, The effect of improving product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the above-mentioned and other purposes, features and advantages of the present invention more obvious and understandable, the following is based on preferred embodiments of the present invention, and is described in detail as follows in conjunction with the accompanying drawings:

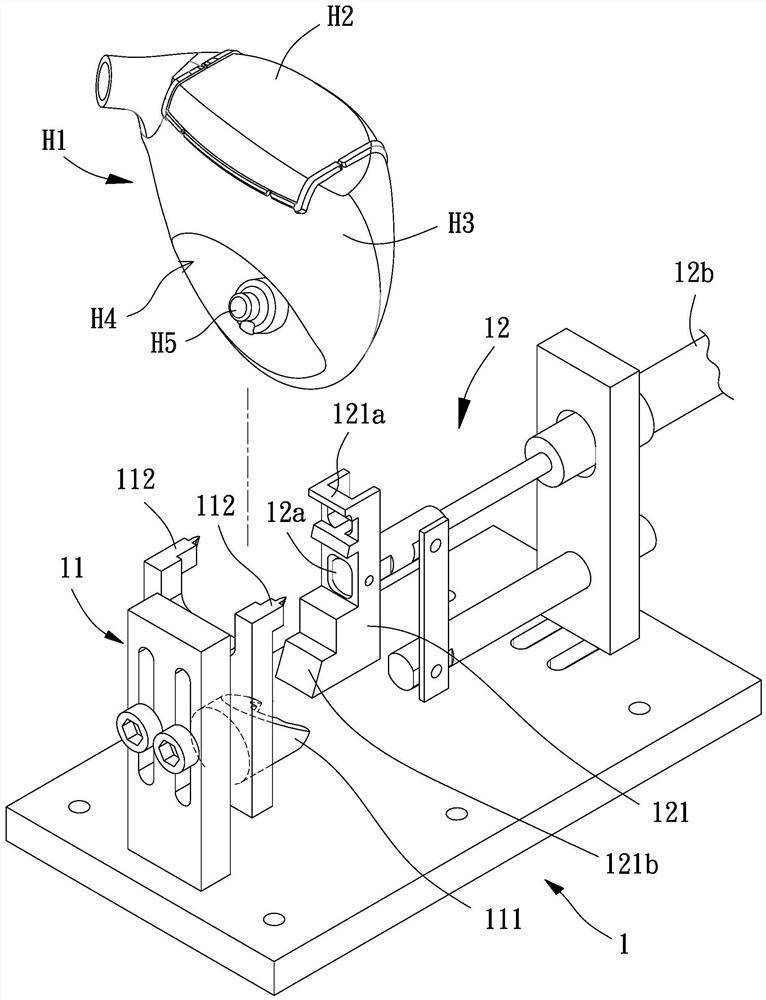

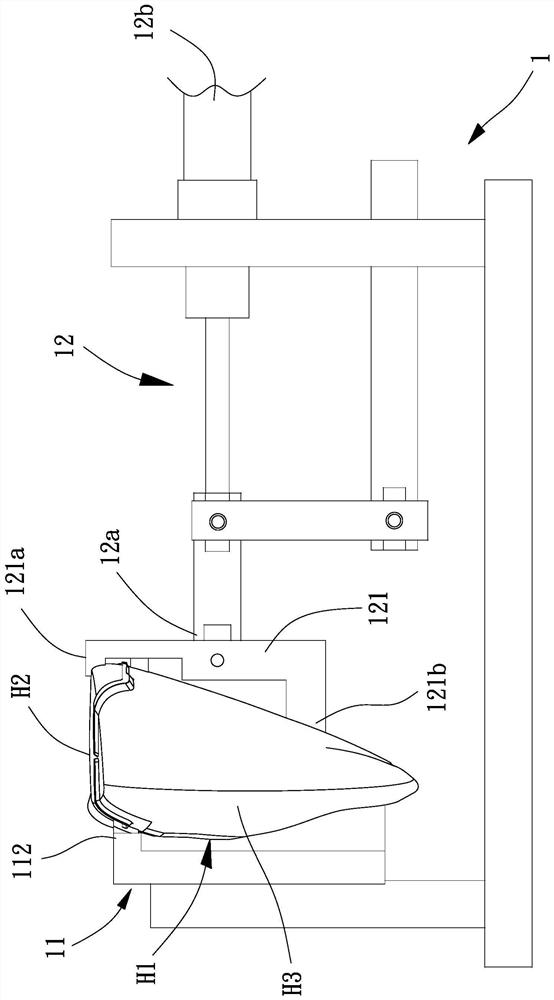

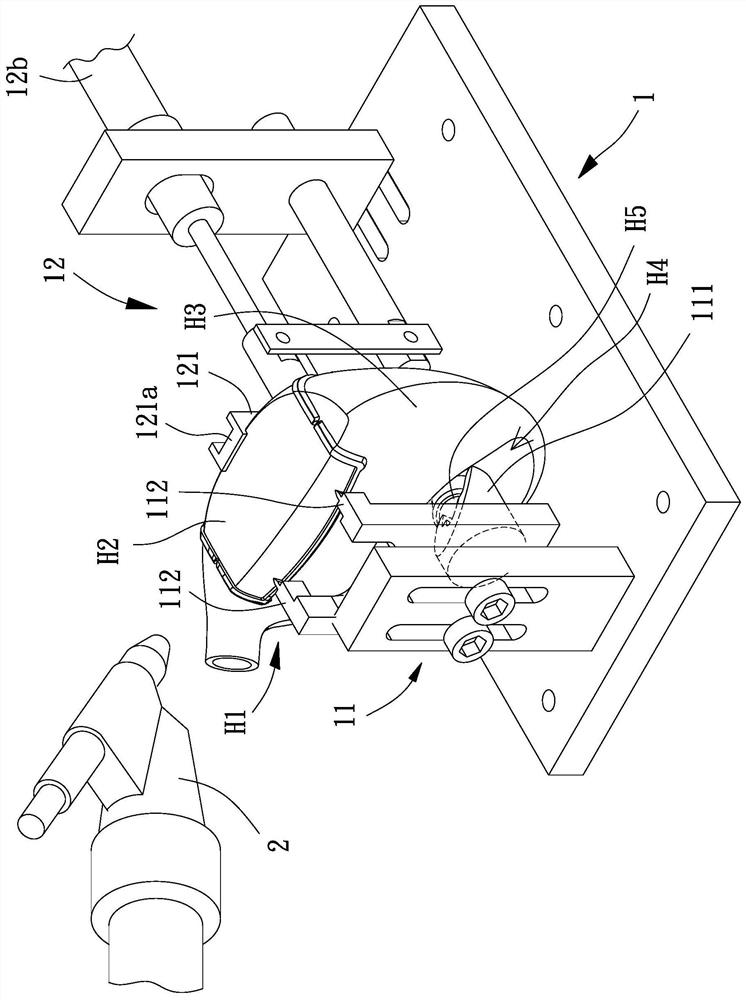

[0038] Please refer to figure 1 , 2 As shown in , 3, an embodiment of the present invention, a golf club head welding method, may include: positioning a semi-finished club head H1 with a positioning device 1, and positioning a semi-finished club head H1 with a welding part 2 Strike panel H2 for soldering.

[0039] The club head semi-finished product H1 can be matched with the striking face plate H2 in advance, and then welded after being positioned by the positioning device 1. In this embodiment, the club head semi-finished product H1 can be made of stainless steel, carbon steel, or alloy steel. , iron-manganese-aluminum or titanium alloy and other metal materials, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com