Air injection structure of air layer resistance reduction device, ship air layer resistance reduction system and air layer resistance reduction ship

A drag reduction device and gas layer technology, applied in the direction of ship hull, hull design, ship construction, etc., can solve the problems affecting the overall strength of the ship, and achieve the effect of saving workload, reducing costs, and facilitating opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

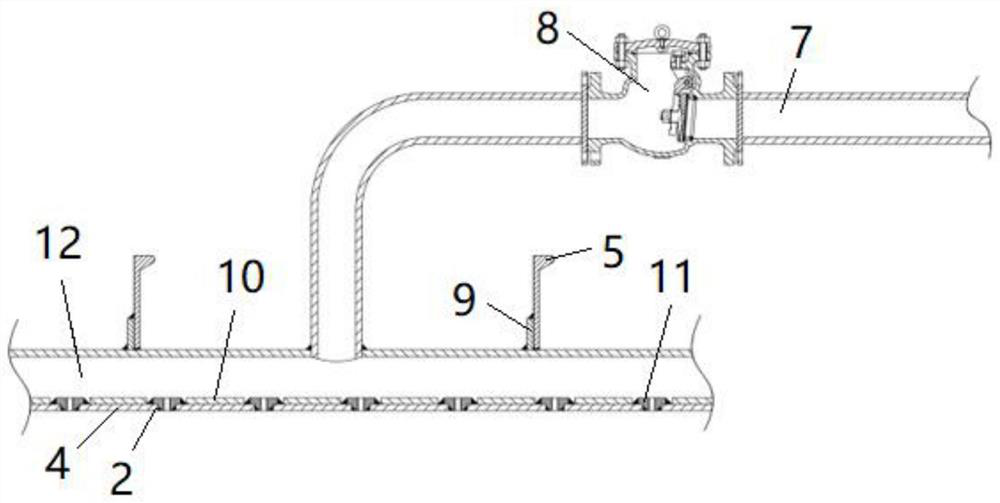

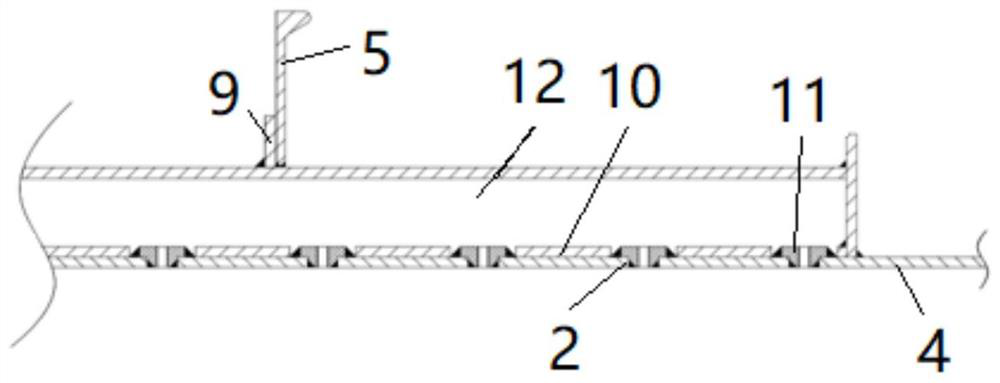

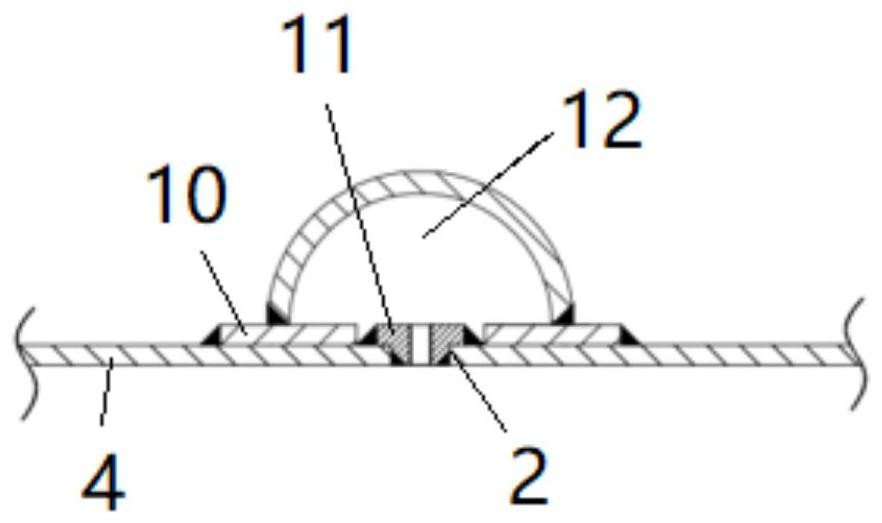

[0035] see Figure 4 to Figure 6 , the present embodiment provides an air injection structure of an air layer drag reduction device, comprising a pressure stabilizing tube 1 and a number of spray holes 2 arranged on the bottom plate 4 of the ship, the stabilizing tube 1 is arranged above the longitudinal 5, and the pressure stabilizing tube 1 The inner chamber is a pressure-stabilizing chamber 12, and the pressure-stabilizing pipe 1 is provided with a number of air delivery pipes 3 corresponding to the nozzle holes 2 one by one.

[0036] In the prior art, the plenum chamber 12 is directly connected with the ship bottom plate 4 (see attached Figures 1 to 3 ), so it will run through the longitudinal bone 5, in order to compensate for the influence of opening holes on the longitudinal bone 5 on the overall strength of the ship, it is necessary to add a longitudinal bone patch 9 to the longitudinal bone 5. However, in this embodiment, the pressure stabilizing chamber 12 is arrang...

Embodiment 2

[0051] This embodiment provides an air layer drag reduction system for a ship, including the air jet structure of the air layer drag reduction device as described in Embodiment 1. Since the air jet structure of the air layer drag reduction device has little influence on the structural strength of the hull, there is no need to cut the longitudinal bone 5. Installation of components such as the longitudinal bone patch 9, the plenum backing plate 10, and the nozzle 11 saves costs, reduces installation procedures and time, and thus enhances the competitiveness of the ship air layer drag reduction system provided by this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com