System for high-speed filling and plug adding and method

A filling and stoppering and high-speed technology, which is applied in pharmaceutical packaging equipment and food fields, can solve problems such as difficulty in ensuring operation stability and positioning deviation, and achieve the effect of improving production efficiency and ensuring stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

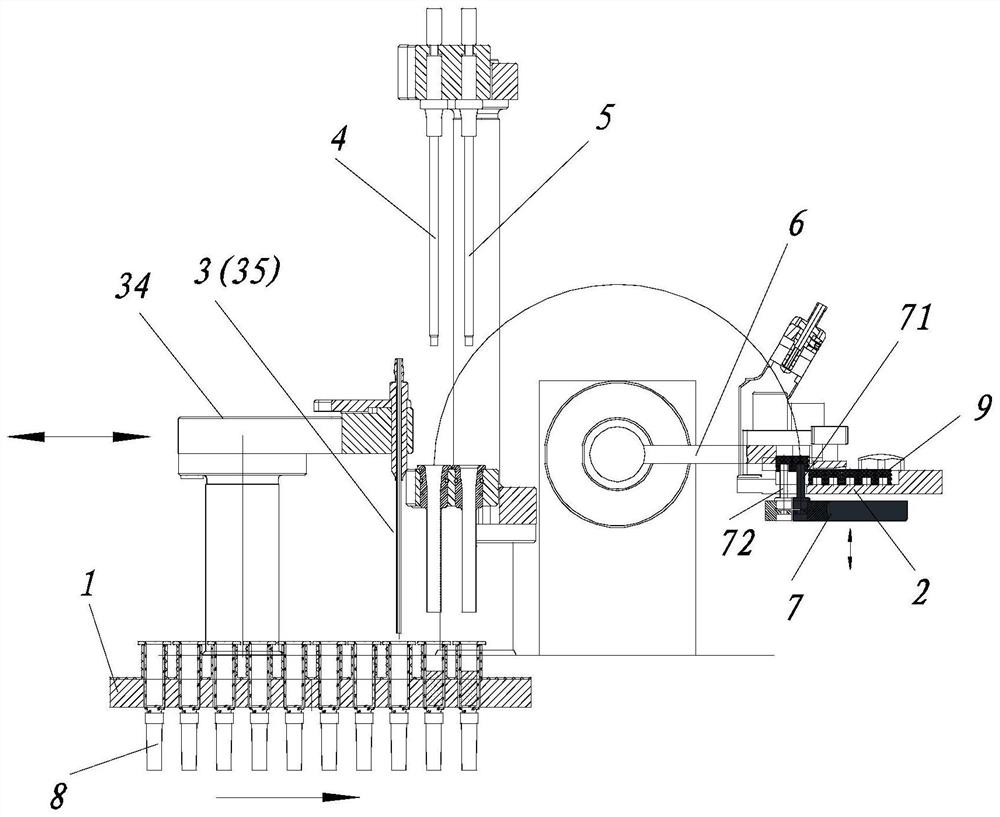

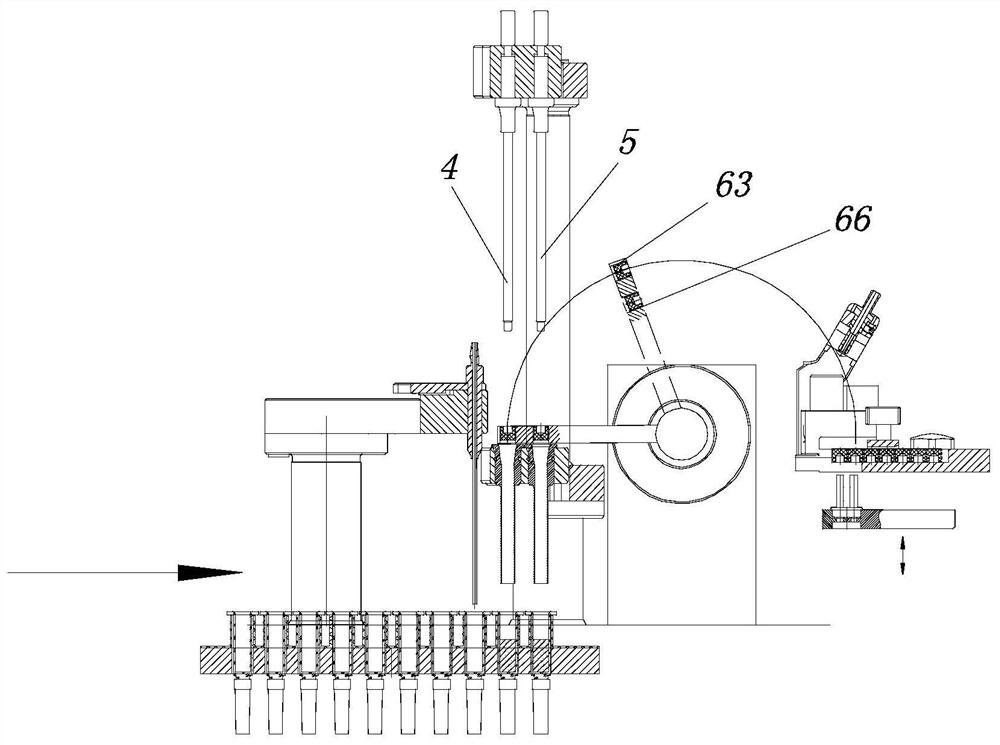

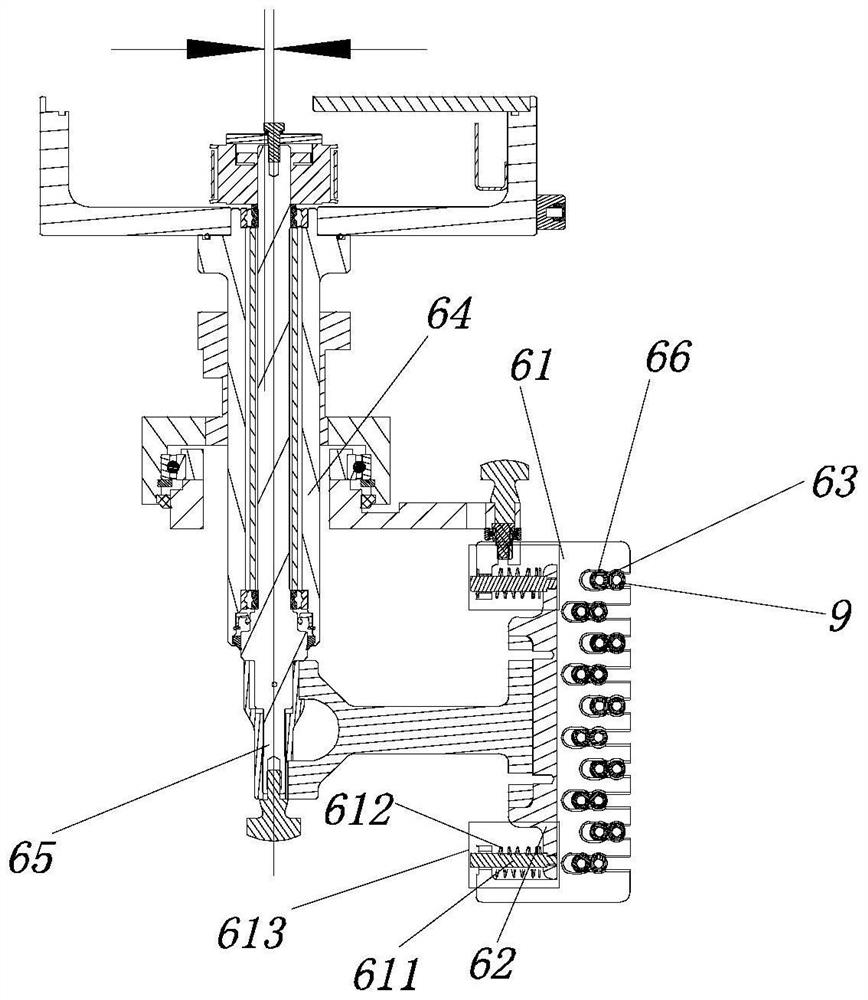

[0039] Figure 1 to Figure 6 An embodiment of the system for high-speed filling and stoppering of the present invention is shown. The system for high-speed filling and stoppering in this embodiment includes a conveying device 1, a stoppering device 2, a filling device 3, a first stoppering Device 4, second stoppering device 5, and rubber stopper transfer device 6 for transferring rubber stoppers 9 to first stoppering device 4 and second stoppering device 5, filling device 3, first stoppering device 4, second stoppering device The device 5, the rubber plug transfer device 6 and the plug feeding device 2 are arranged in sequence along the conveying device 1. The rubber plug transfer device 6 includes a first plugging plate 61 with a first rubber stopper positioning channel 63, and a second rubber stopper positioning channel. The second plugging plate 62 of 66, and the eccentric shaft assembly for driving the first plugging plate 61 and the second plugging plate 62 to rotate to a...

Embodiment 2

[0048] Figure 7 to Figure 8 It shows another embodiment of the system for high-speed filling and stoppering of the present invention. The system for high-speed filling and stoppering of this embodiment is basically the same as that of Embodiment 1, the difference is that in this embodiment, the eccentric The shaft assembly includes an eccentrically arranged first rotating shaft 64 and a second rotating shaft 65, the first rotating shaft 64 is connected to the first plugging plate 61, the second rotating shaft 65 is connected to the second plugging plate 62, and the first rotating shaft 64 is set On a sliding mechanism 67, that is, the eccentricity between the first rotating shaft 64 and the second rotating shaft 65 can be adjusted through the sliding mechanism 67 to adapt to the filling and stoppering of containers of different specifications. The disadvantage is that the volume of the equipment increases , Occupying plant area increased. Of course, in other embodiments, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com