Automatic sewing device for sneaker processing

A suture device and sports shoe technology, which is applied in the direction of sewing machine control device, clothing piece collection device, sewing equipment, etc., can solve the problems of accidents, troublesome and inconvenient fetching back and forth, and increased failure rate of sewing machines, so as to improve work efficiency. Efficiency, avoiding the effect of wasting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

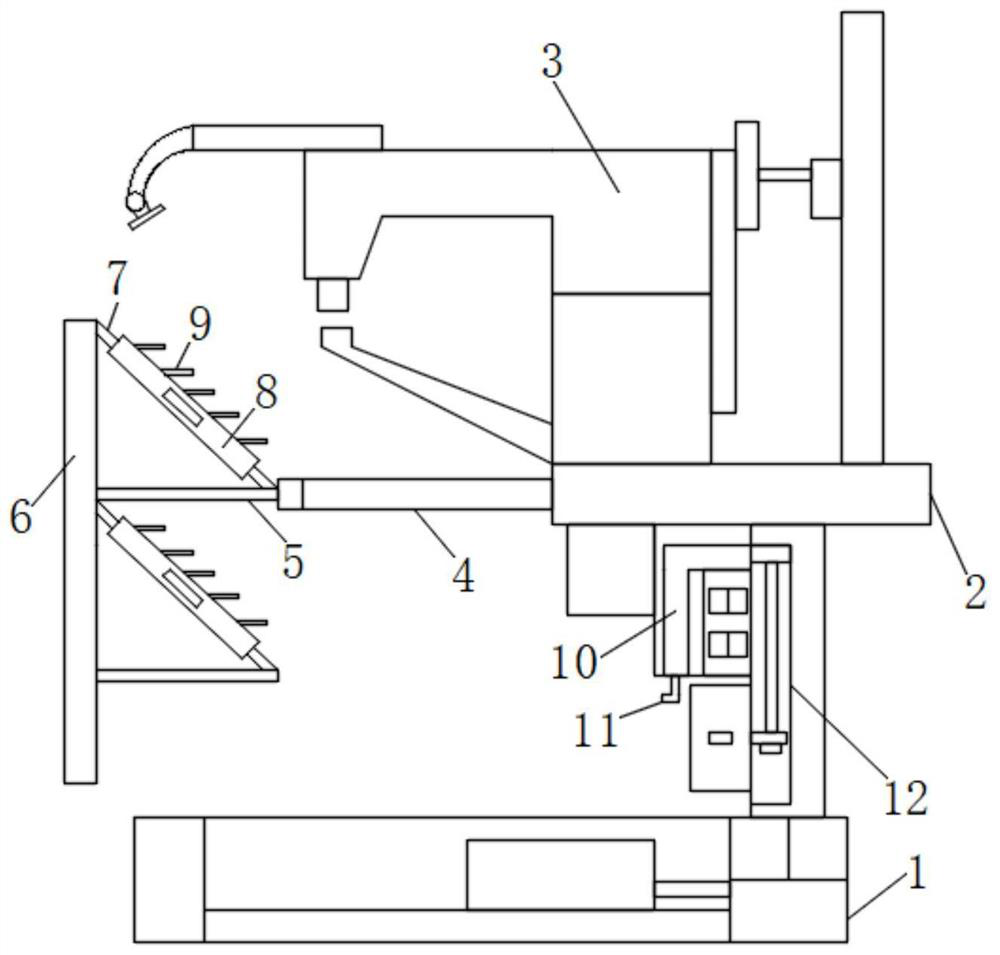

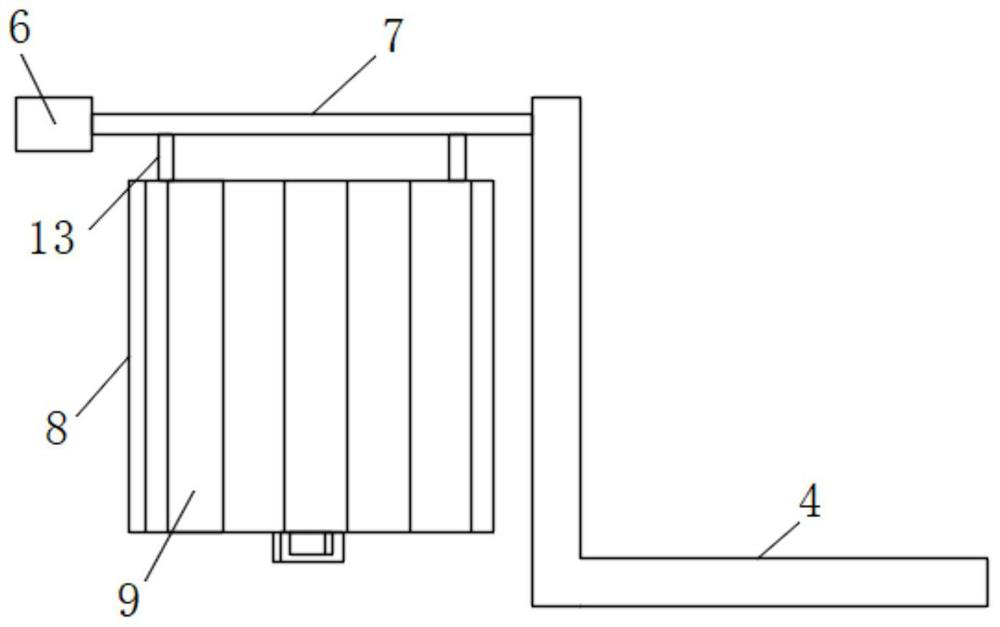

[0021] see figure 1 and figure 2 , the present invention provides a technical solution: an automatic sewing device for sports shoe processing, comprising a base 1, a workbench 2, and a machine base 3, the side of the workbench 2 is provided with a fixed block 4, and the side of the fixed block 4 is provided with a fixed Rod 5, fixed beam 6, two parallel fixed rods 5 are horizontally located on the surface of fixed beam 6, and the side of fixed beam 6 is provided with two parallel stabilizing rods 7, and stabilizing rod 7 is provided with two parallel limit rods 13, the outer side of the limit rod 13 is provided with a slide plate 8, and the surface of the slide plate 8 is provided with five placement plates 9, and several uppers and soles are placed on the placement plates 9 on the upper side of the slide plate 8, and the uppers and The sole can be placed on the placement plate 9 positioned at the lower side after the stitching is completed, and many pairs of uppers and sole...

Embodiment 2

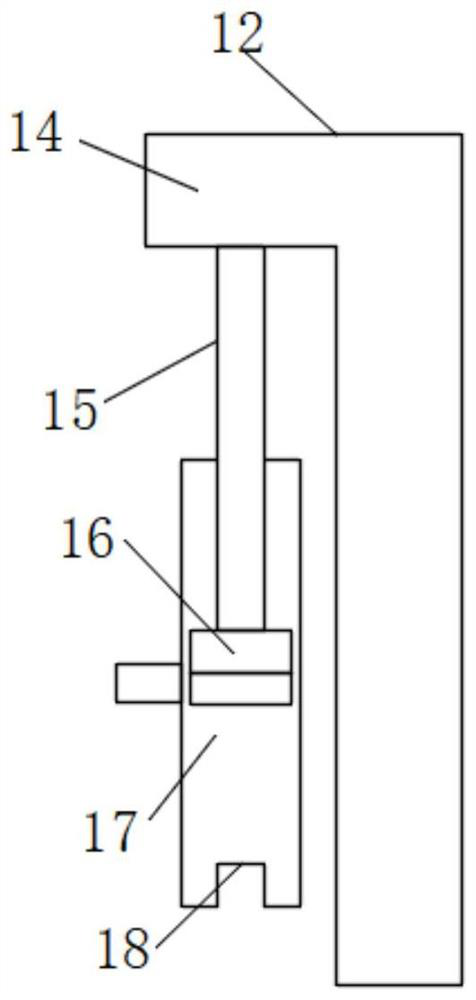

[0027] see Figure 1 to Figure 3 , the present invention provides a technical solution: an automatic sewing device for sports shoe processing, comprising a base 1, a workbench 2, and a machine base 3, the side of the workbench 2 is provided with a fixed block 4, and the side of the fixed block 4 is provided with a fixed Rod 5, fixed beam 6, two parallel fixed rods 5 are horizontally located on the surface of fixed beam 6, and the side of fixed beam 6 is provided with two parallel stabilizing rods 7, and stabilizing rod 7 is provided with two parallel limit rods 13, the outer side of the limit rod 13 is provided with a slide plate 8, and the surface of the slide plate 8 is provided with five placement plates 9, and several uppers and soles are placed on the placement plates 9 on the upper side of the slide plate 8, and the uppers and The sole can be placed on the placement plate 9 located at the lower side after the sewing is completed, and multiple pairs of uppers and soles ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com