Magnetic switch installation structure for controlling stroke of large-diameter cylinder

A magnetic switch and installation structure technology, applied in the direction of fluid pressure actuation device, etc., can solve the problems affecting the precision of piston rod movement, affecting the control precision of mechanical equipment, and the processing precision of cylinder piston rod and cylinder body is difficult to guarantee, etc., to achieve the improvement The effect of movement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

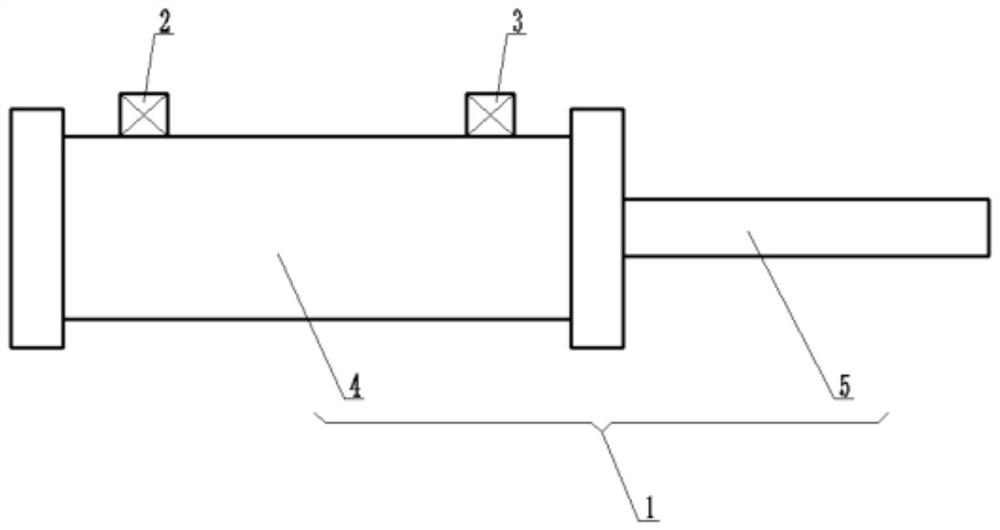

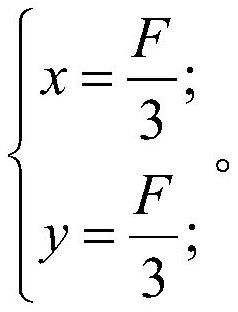

[0019] like figure 1 As shown, the present invention provides a building material performance testing system, including a cylinder 1, a magnetic switch A2 and a magnetic switch B3, the cylinder 1 includes a cylinder 4 and a piston rod 5 that can reciprocate along the length of the cylinder 4, and the magnetic switch A2 and the magnetic switch B3 are fixedly installed on the outer surface of the cylinder 4, assuming that the stroke of the cylinder 1 is F, the distance between the installation position of the magnetic switch A2 and the bottom of the cylinder 4 is x, and the installation position of the magnetic switch B3 is relative to the top of the cylinder 4 The distance is y, then F, x, y satisfy the following relationship:

[0020]

[0021] Further, it is preferable that the magnetic switch A2 is a magnetic switch with an au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com