Water hammer retarding assembly and electromagnetic valve with same

A component and water hammer technology, applied in the field of solenoid valves, can solve the problems of insignificant actual effect and failure to achieve water hammer performance, and achieve the effects of improving service life, slowing down water flow speed, and delaying closing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

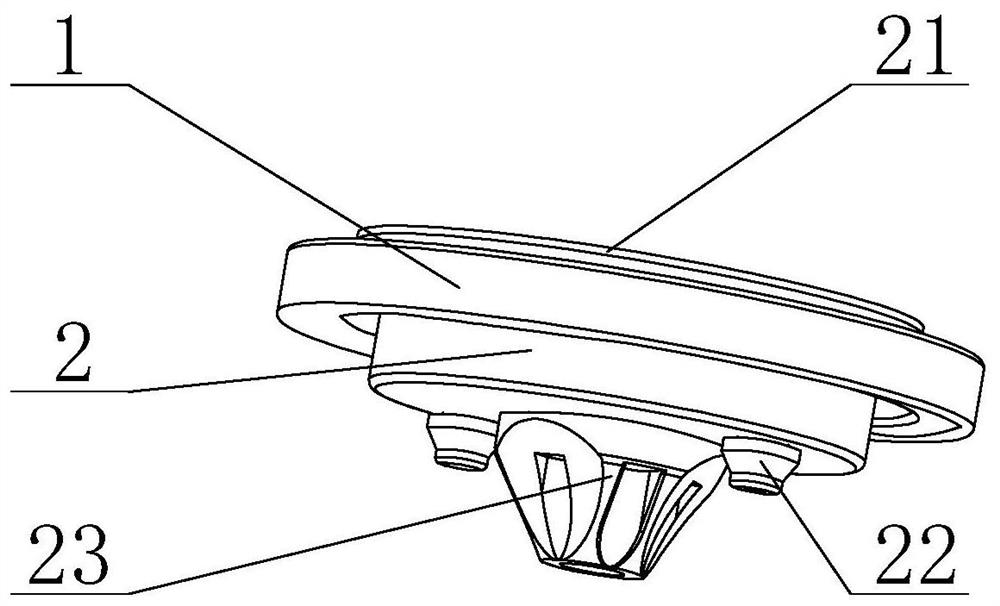

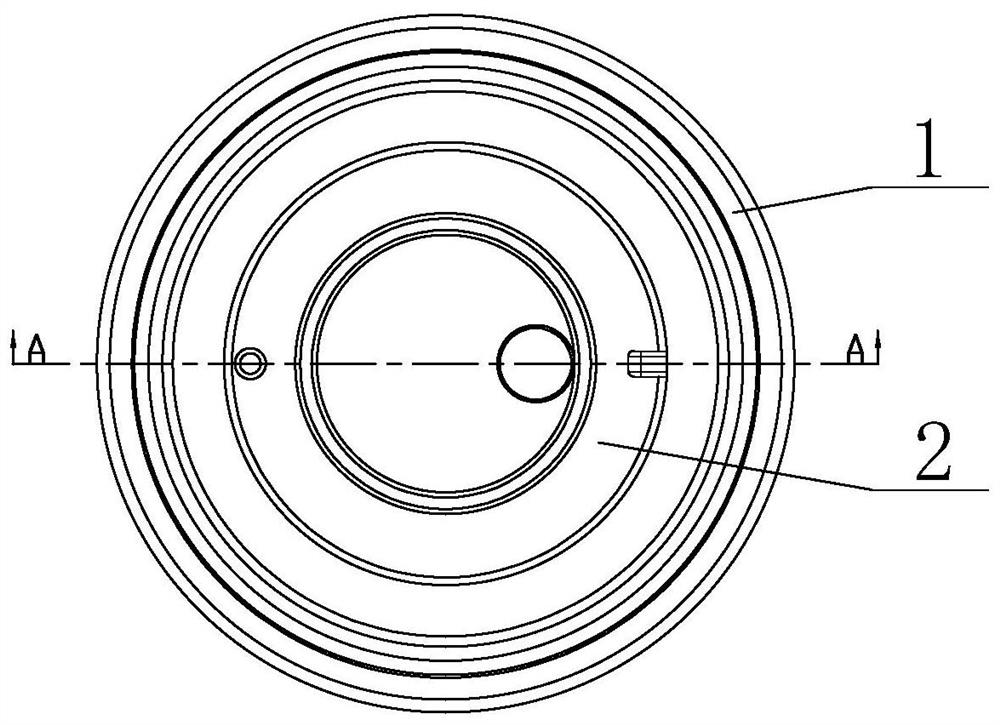

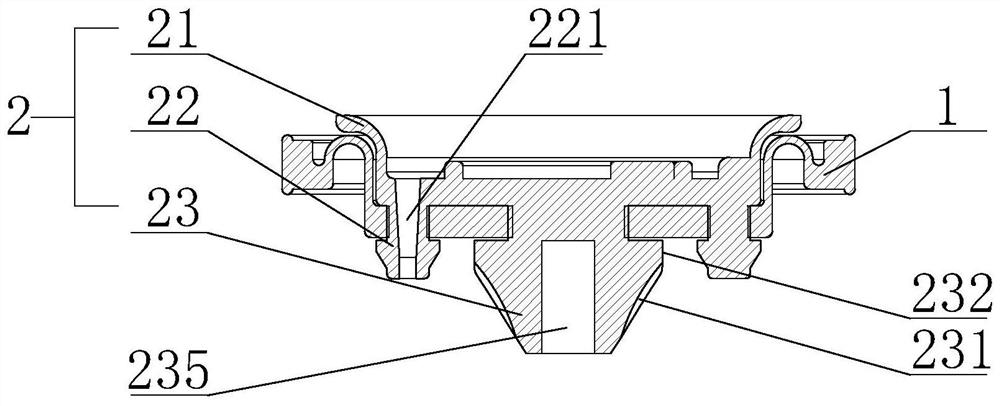

[0024] Such as Figure 1-6 As shown, the present invention is a water hammer mitigation assembly, including a diaphragm 1, a diaphragm frame 2 connected to the diaphragm 1, and the diaphragm frame 2 includes a base 21 arranged on one side of the diaphragm 1, and the base 21 A guide part 22 and a raised part 23 are respectively formed on the top, and the guide part 22 and the raised part 23 are arranged on the other side of the diaphragm 1 through the diaphragm 1, and a guide part 22 is formed on the guide part 22. hole 221, the guide hole 211 runs through the base 21 and the guide part 22, the upper end of the raised part 23 is a conical body 231, the bottom end of the raised part 23 is a cylinder 232, the raised part 23 The outer periphery forms 3 cut planes 233 equiangularly arranged and vertically across the frustum of the cone 231 and the cylinder 232. The lower cutting surface 233b of the lower cutting surface 233b and the bottom surface of the cylinder 232 form a comple...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap