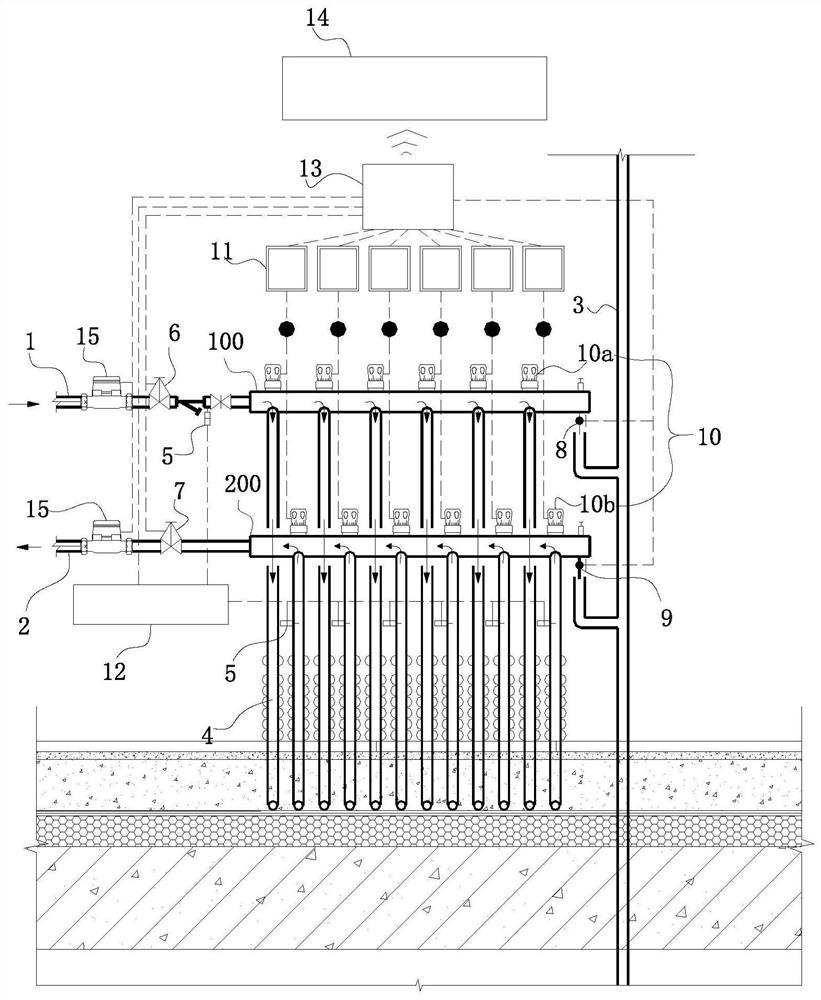

Floor heating water distributing and collecting device and flushing method thereof

A sub-collector and floor heating technology, which is applied in the field of sub-collectors for floor heating and its flushing, can solve the problems of high purchase cost of pressure detection devices, reduced heating effect, and blocked pipe network, etc., to solve the problem of declining heating efficiency and reducing economic costs. The effect of burdening and reducing the cost of employment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

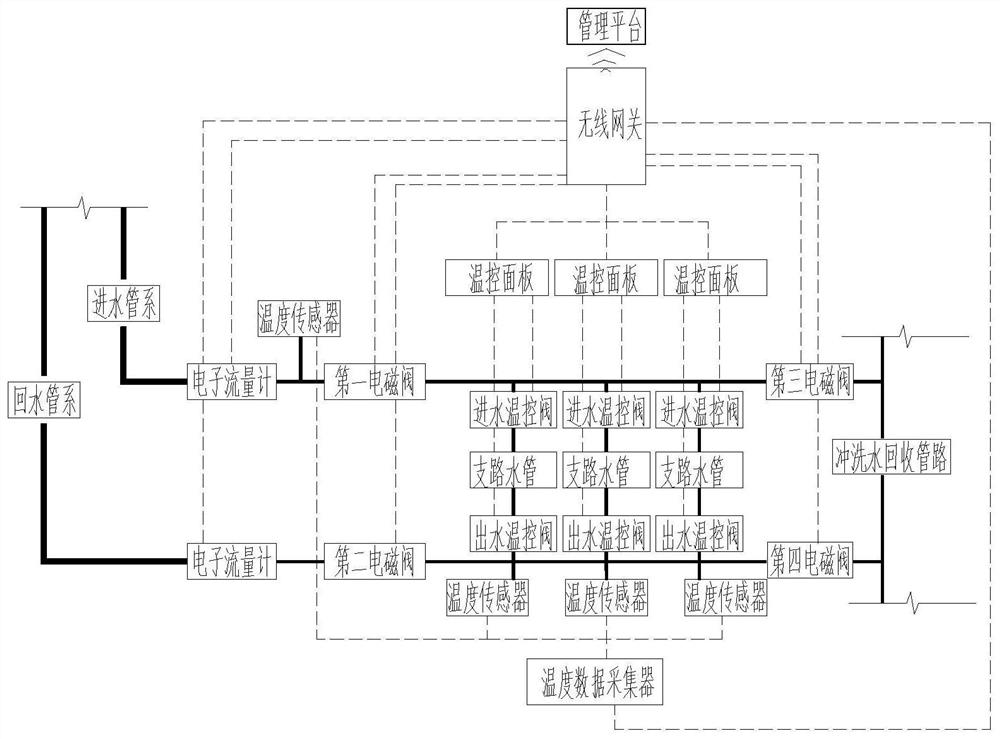

[0057] A method for flushing a floor heating sub-collector, comprising the following steps:

[0058] Step 1. Obtain the temperature data of the water inlet pipe system 1 and each branch water pipe 4 in real time, as well as the indoor temperature data of the space where each branch water pipe 4 is located;

[0059] Step 2. Calculate the temperature difference between the water inlet pipe system 1 and each branch water pipe 4, and judge whether the temperature difference is greater than the preset temperature difference. If the temperature difference is greater than the preset temperature difference, execute the next step; otherwise, do not execute;

[0060] Step 3, extract the indoor temperature data of the space where the branch water pipe 4 is located with a temperature difference value greater than the preset temperature difference value, and judge whether the indoor temperature is lower than the preset temperature value, if it is smaller, execute the next step, otherwise do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com