Water meter shell pressure detection device and detection method

A detection device and water meter case technology, applied in the direction of measuring device, measuring fluid pressure, using stable tension/pressure to test material strength, etc., can solve the problem that the detection results are prone to incompleteness, inconvenient multi-point detection, and inability to adapt to different Standardized water meter detection and other issues, to achieve the effect of stable detection, stable clamping, and airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

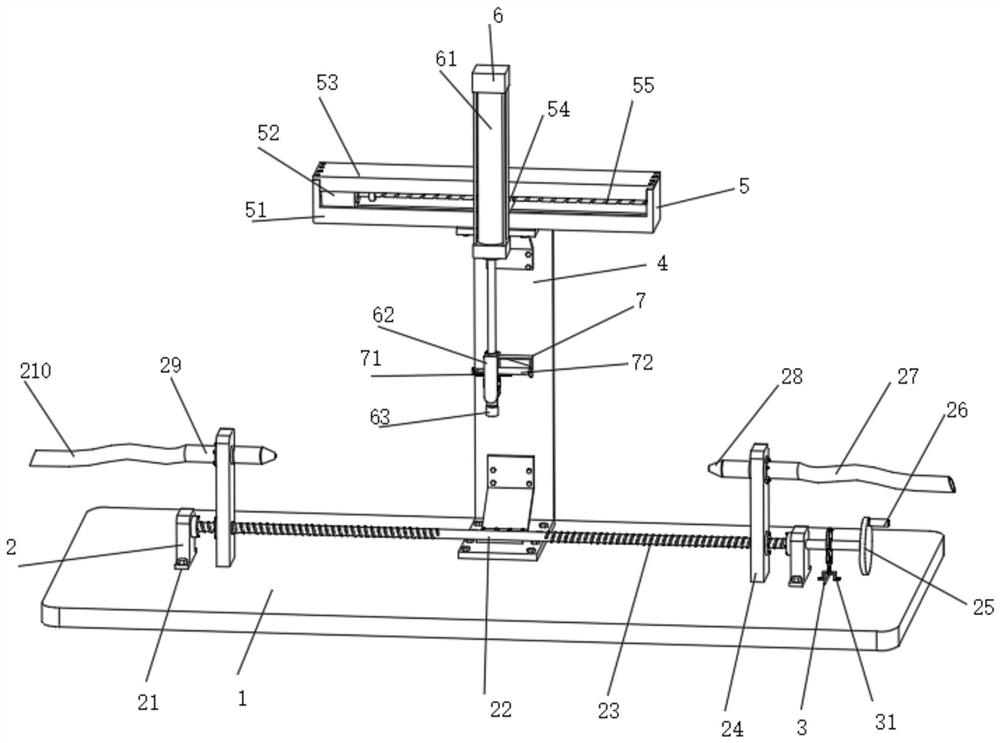

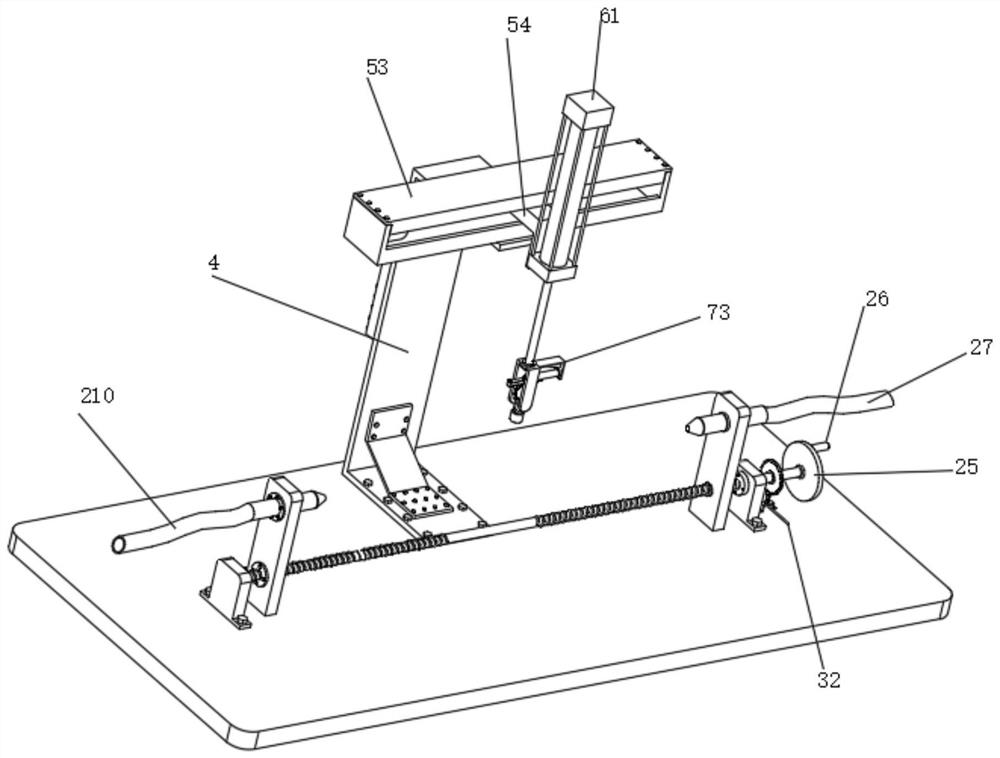

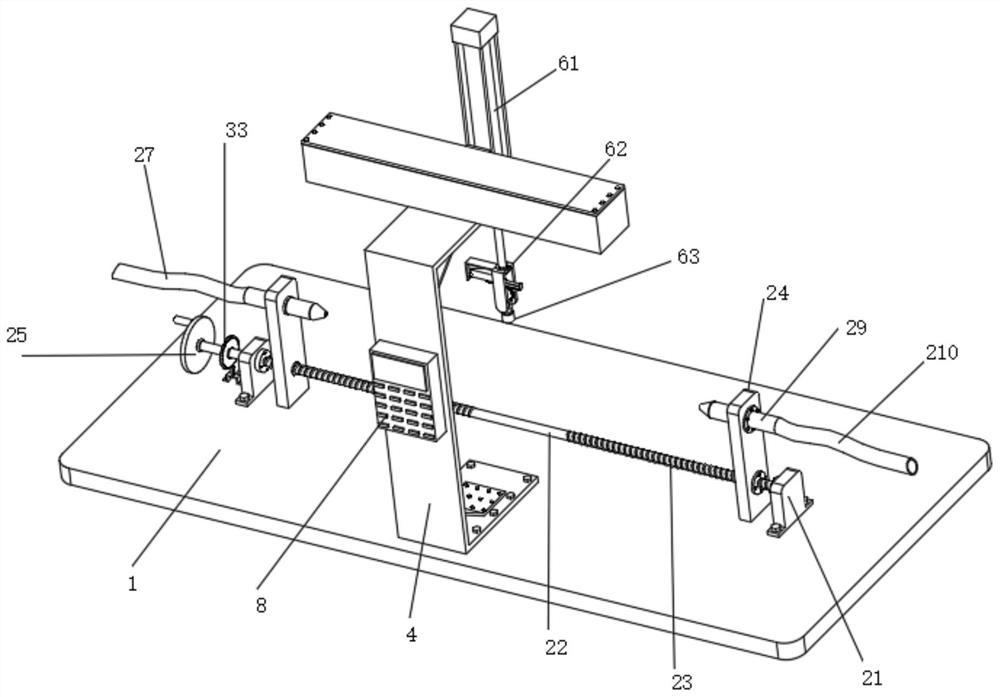

[0042] Such as figure 1 , 2 , 3, 6, and 8, a water meter casing pressure detection device includes a base 1, the top middle end of the base 1 is provided with a water meter clamping structure 2 for fixing the water meter, and the water meter clamping structure 2 includes a first convex Block 21, rotating rod 22, screw groove 23, slide plate 24, the first turntable 25, rocking bar 26, water inlet hose 27, rubber tapered pipe 28, horizontal pipe 29, water outlet hose 210 and tapered pipe 211, the first Convex block 21 is symmetrically fixedly installed on the top of base 1, and the first protruding block 21 is rotatably connected with rotating rod 22 by the bearing that is fixedly installed, and the right end of rotating rod 22 is fixedly connected with first rotating disc 25, and the first rotating disc 25 The outer edge of the side wall is fixedly connected with a rocking bar 26 for promoting the rotation of the first turntable 25, and the outer wall of the rocking bar 26 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com