Gardening tool

A technology of garden tools and hub motors, applied in agricultural machinery and tools, harvesters, agriculture, etc., can solve the problems of unsatisfactory performance of the whole machine, low energy utilization efficiency, and heavy weight of the lawn pusher

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

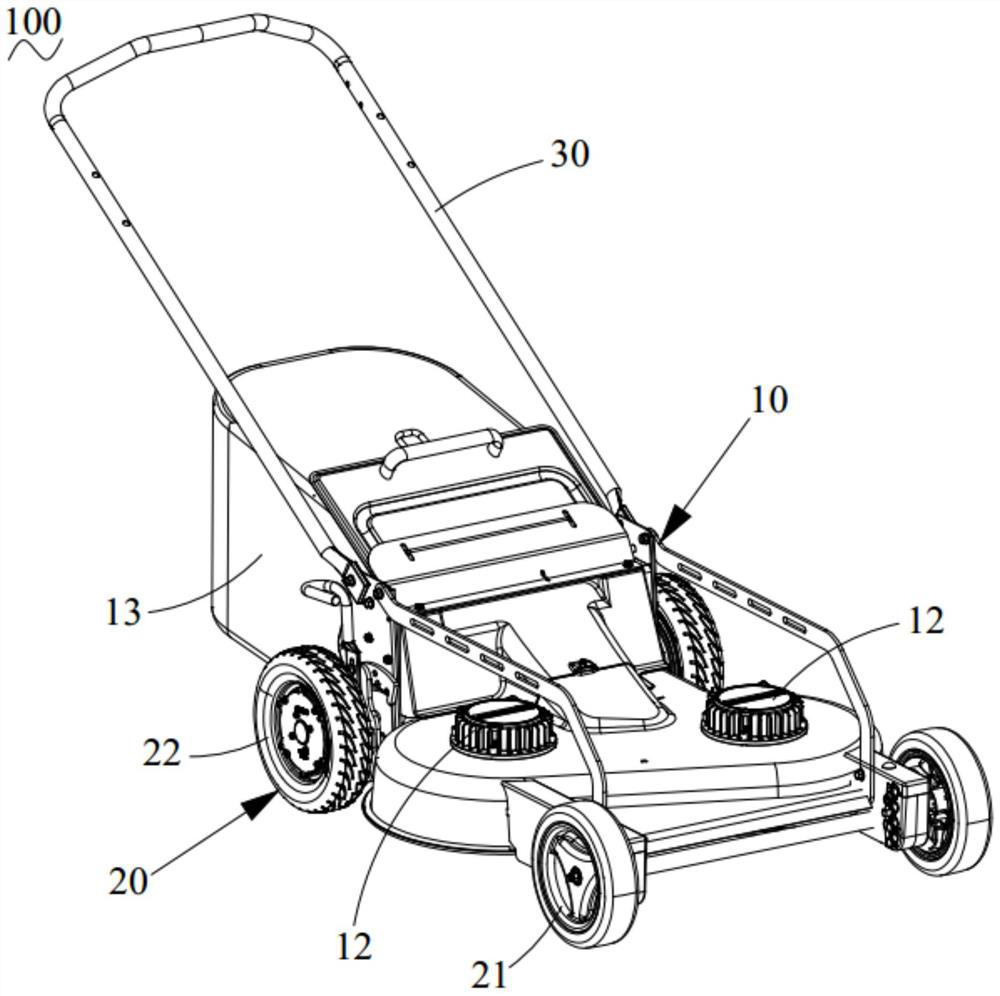

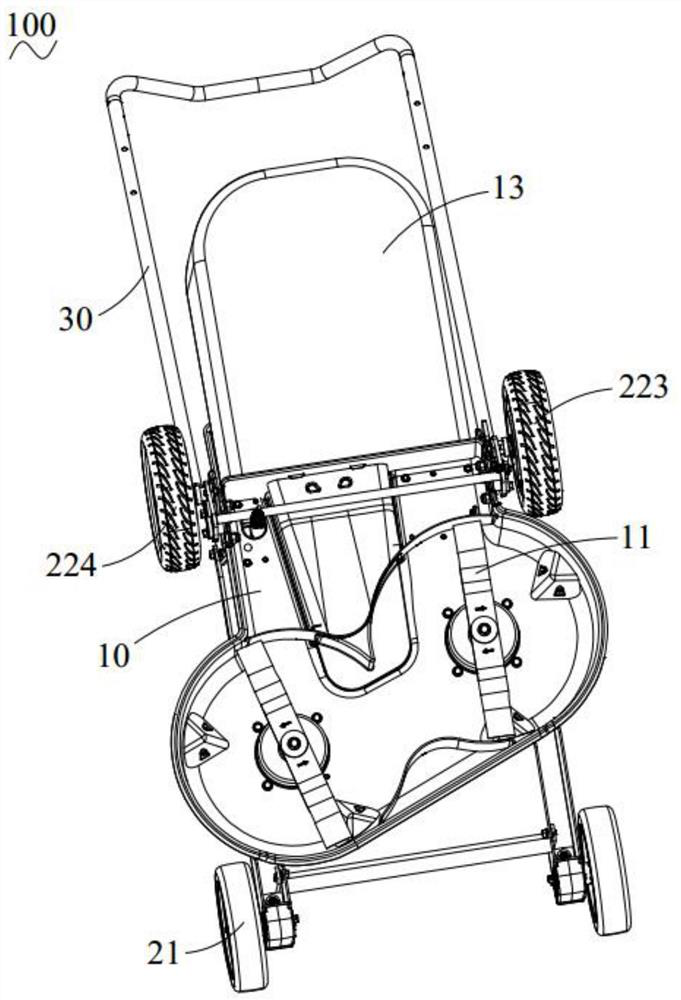

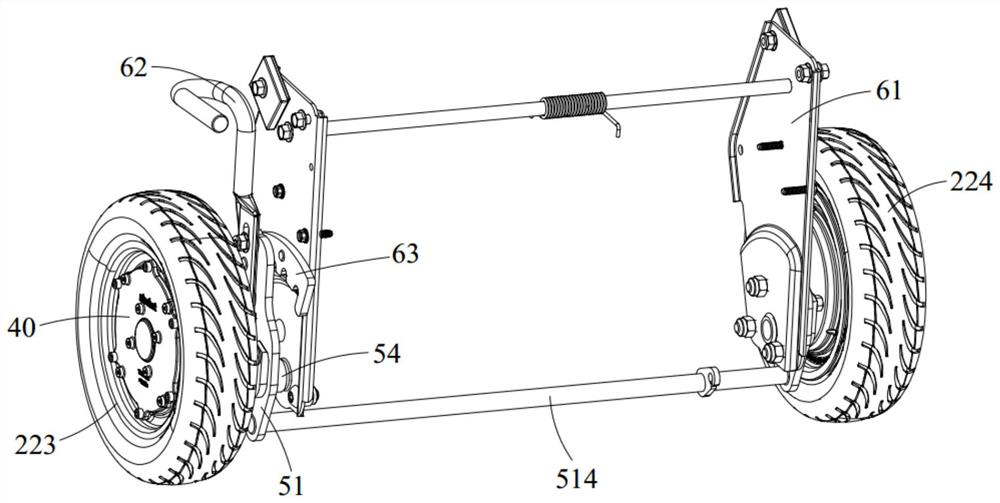

[0030] Such as figure 1 and figure 2 As shown, the present invention discloses a garden tool 100, which includes a body 10, walking wheels 20 for supporting the body 10 and driving the body 10 to move, and a handrail connected with the body 10 for the user to push Bracket 30. In this embodiment, the garden tool 100 is a lawn pusher, which is provided with two blades (ie, functional components) 11, the two blades 11 are arranged at the middle position of the bottom of the body 10 and arranged in a staggered front and rear, the two The blades 11 are individually driven by a motor (ie a power assembly) 12 to mow grass, and the motor 12 is a waterproof motor. The rear portion of the mower 100 is provided with a grass collecting bag 13, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com