Cleaning assembly and crude oil filter element cleaning device

A technology for cleaning devices and filters, applied in filter regeneration, filtration separation, chemical instruments and methods, etc., can solve problems such as low efficiency of cleaning methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

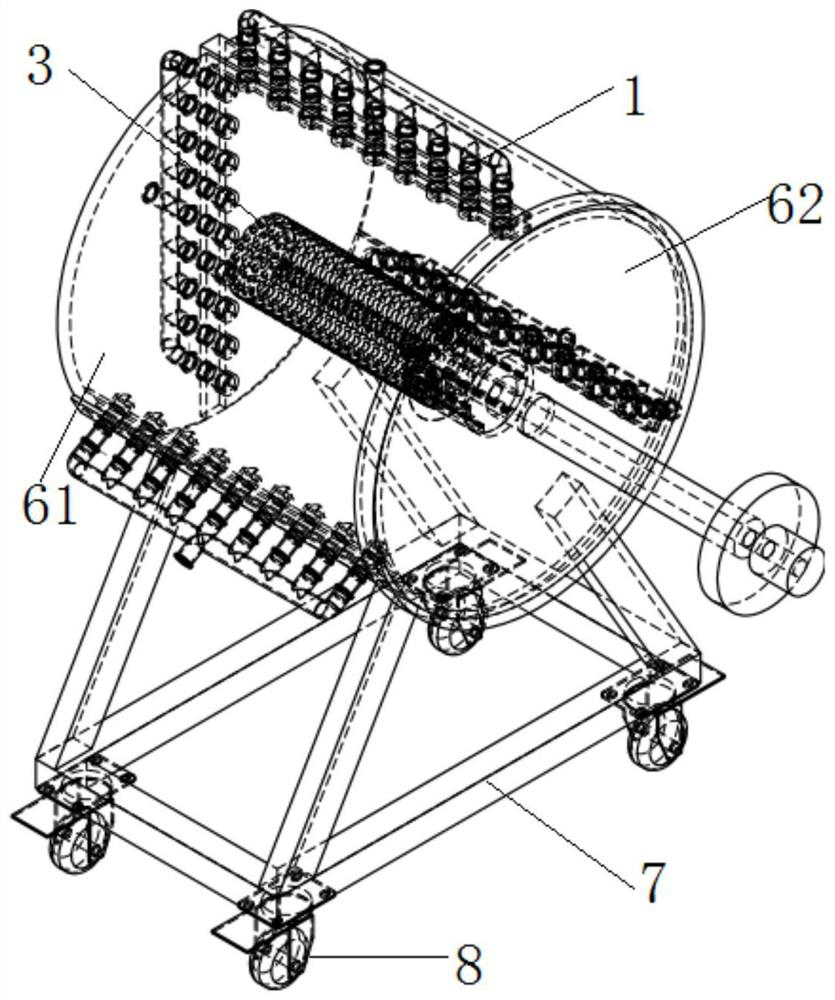

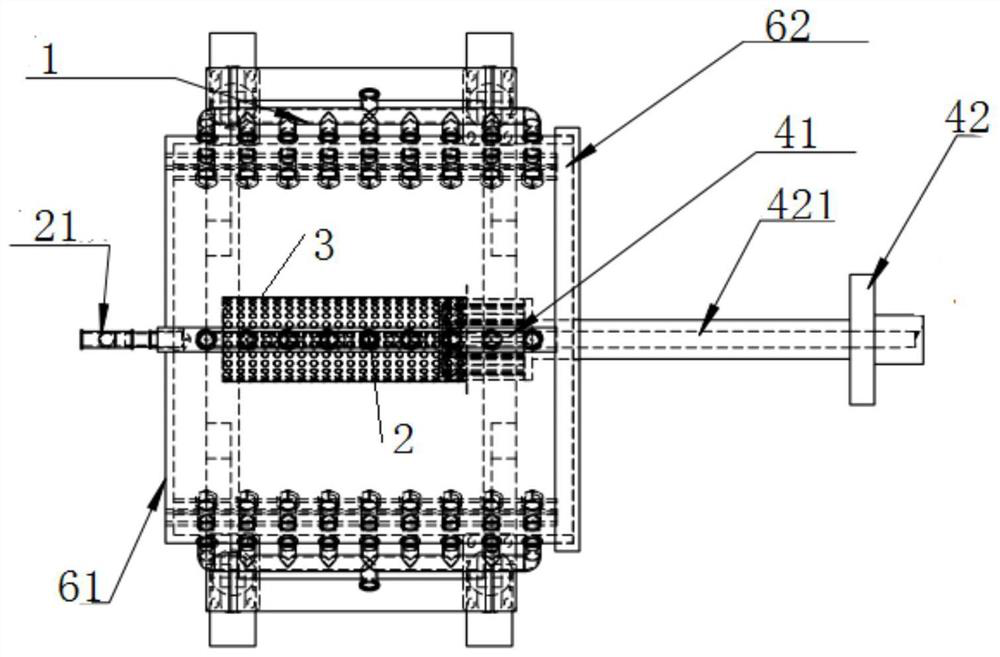

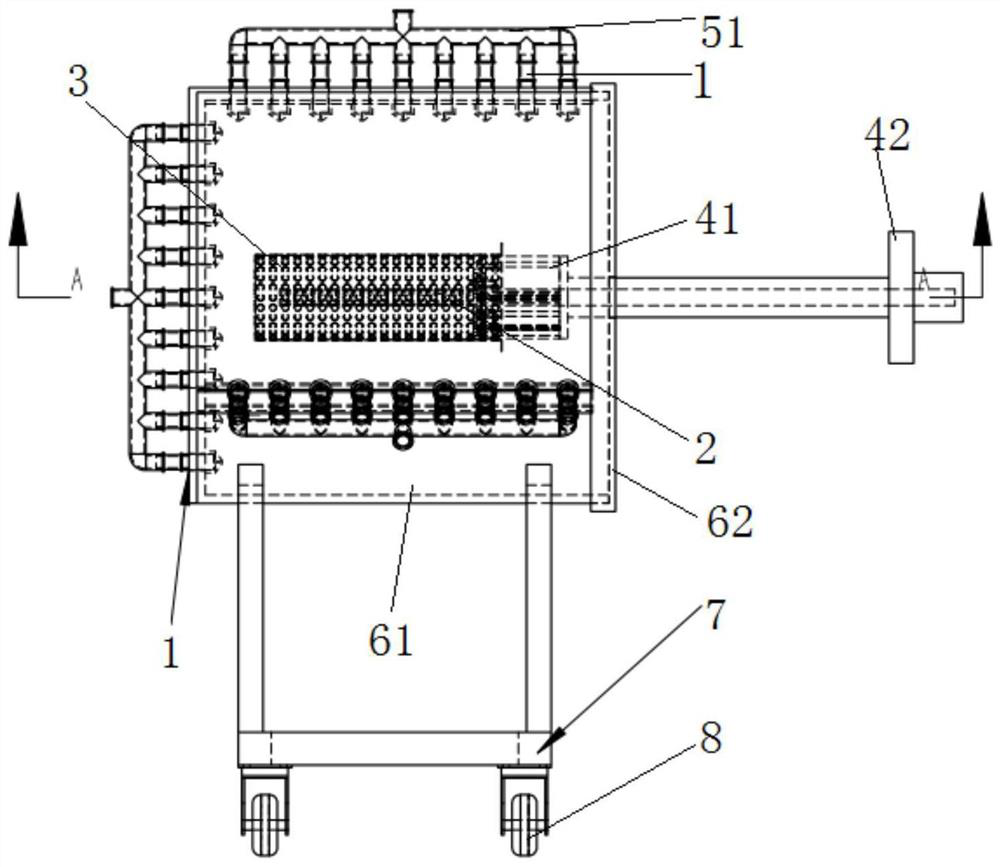

[0039] Such as Figure 1-Figure 8 As shown, this embodiment provides a cleaning assembly, including a fixing mechanism and a spraying mechanism, wherein: the fixing mechanism is detachably connected to the filter element 3, and the spraying mechanism includes an outer spray nozzle 1 capable of spraying high-pressure cleaning fluid and / or the inner spray nozzle 2, the outer spray nozzle 1 is located on the periphery of the fixing mechanism for spraying the outer wall of the filter element 3; the inner spray nozzle 2 extends into the filter element 3 on the fixing mechanism for spraying the inner wall of the filter element 3 .

[0040] In order to improve the cleaning effect of the filter element 3, see Figure 1-Figure 4 As shown, the spray mechanism in this embodiment includes an outer spray nozzle 1 and an inner spray nozzle 2 capable of spraying high-pressure cleaning liquid, and the outer spray nozzle 1 is located at the periphery of the fixing mechanism for spraying the ...

Embodiment 2

[0052] see figure 1 , Figure 7 with Figure 8 As shown, this embodiment provides a crude oil filter element cleaning device, including a barrel body and the above-mentioned cleaning assembly, the outer spray nozzle 1 is located on the inner wall of the barrel, and the fixing mechanism and the inner spray nozzle 2 are located in the barrel. The liquid inlet main pipe 52 is located at the periphery of the staving, and the water diversion main pipe is located inside or outside the staving.

[0053] The crude oil filter element cleaning device of this embodiment is set as the structure of the barrel, the cleaning assembly is arranged in the barrel, and the filter element 3 connected in the barrel is sprayed by a fixing mechanism, and the high-pressure cleaning liquid is sprayed in the barrel , and the cleaned dirty liquid is located in the bucket body, preventing the dirty liquid from flowing out to the cleaning site, and while effectively cleaning the filter element 3, it ensu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com