Auxiliary cooling and cleaning system for cold rolling mill

A technology for cleaning systems and cold rolling mills, applied in the field of cold rolling mills, can solve the problem that the cooling system cannot meet the cooling and cooling requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

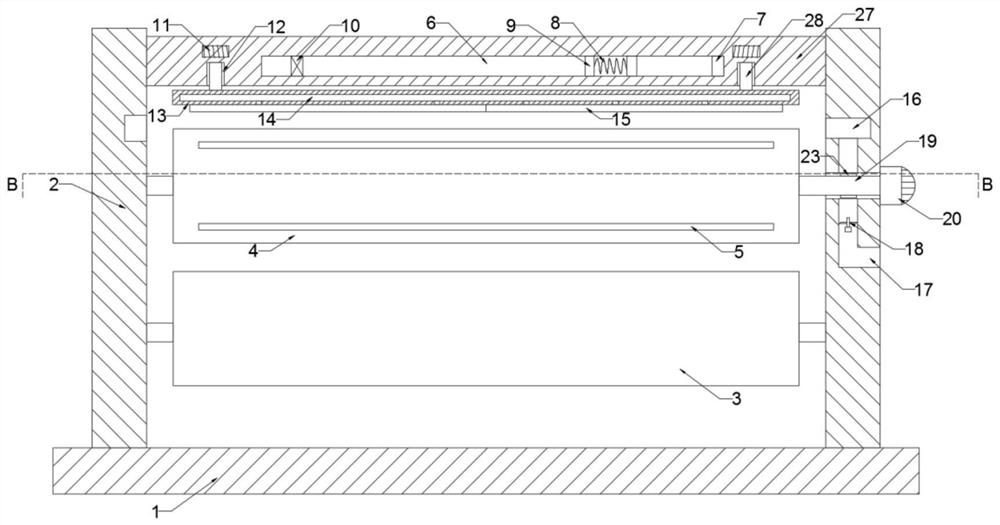

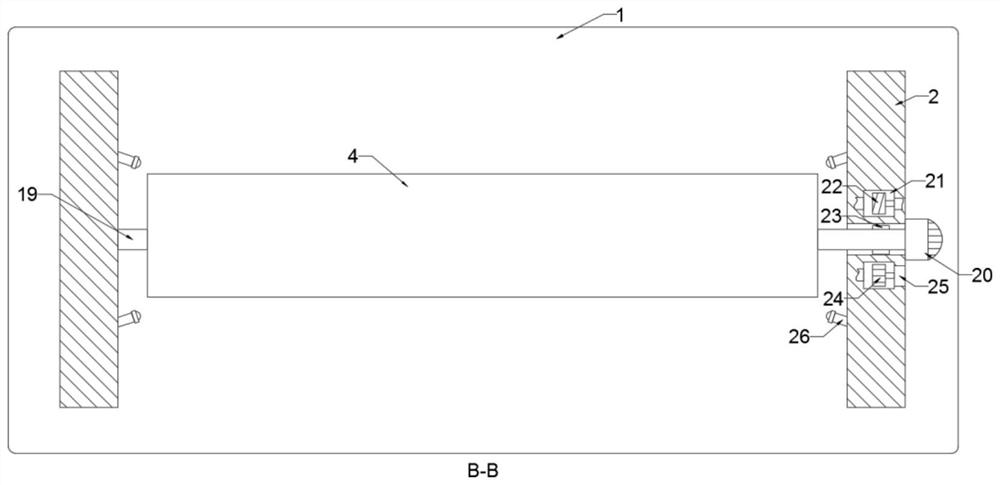

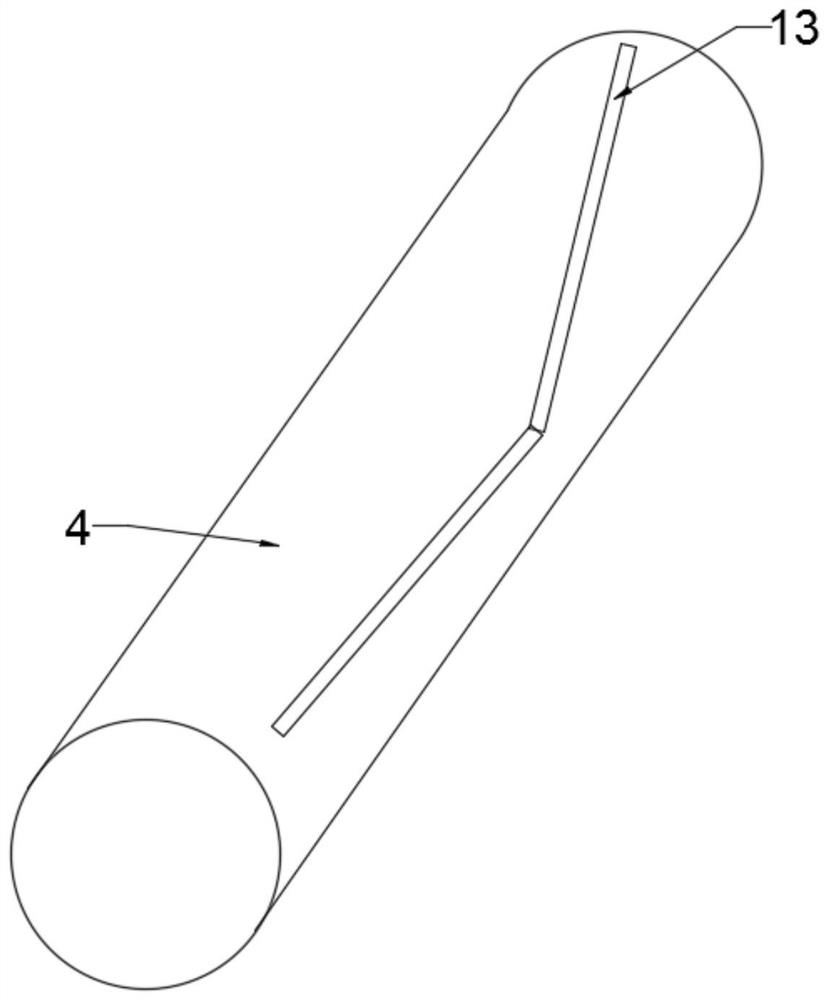

[0021] refer to Figure 1-3 , an auxiliary cooling and cleaning system for a cold rolling mill, comprising a base 1 and a support plate 2 symmetrically welded and fixed on the top of the base 1, a motor 20 is welded and fixed on the side wall of the support plate 2, and a rotating shaft 19 is welded and fixed on the output end of the motor 20, The rotating shaft 19 penetrates through the side walls of the support plates 2 and is welded and fixed to work rolls 4. The load-bearing rolls 3 are rotatably connected between the side walls of the support plates 2. The tops of the two support plates 2 are jointly welded and fixed with a rectangular plate 27. The inner walls of the work rolls 4 are provided with The bottom of the heat conducting sheet 5 and the rectangular plate 27 are symmetrically provided with two sets of grooves 12, and the grooves 12 are slidingly connected with a magnetic rod 28, the bottom of the magnetic rod 28 is welded and fixed with a scraper 13, and the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com