Press fitting tool for positioning pin bush

A technology for press-fitting tools and positioning pin sleeves, which is applied in the direction of manufacturing tools, hand-held tools, etc., and can solve problems such as locked camshaft burning, positioning errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

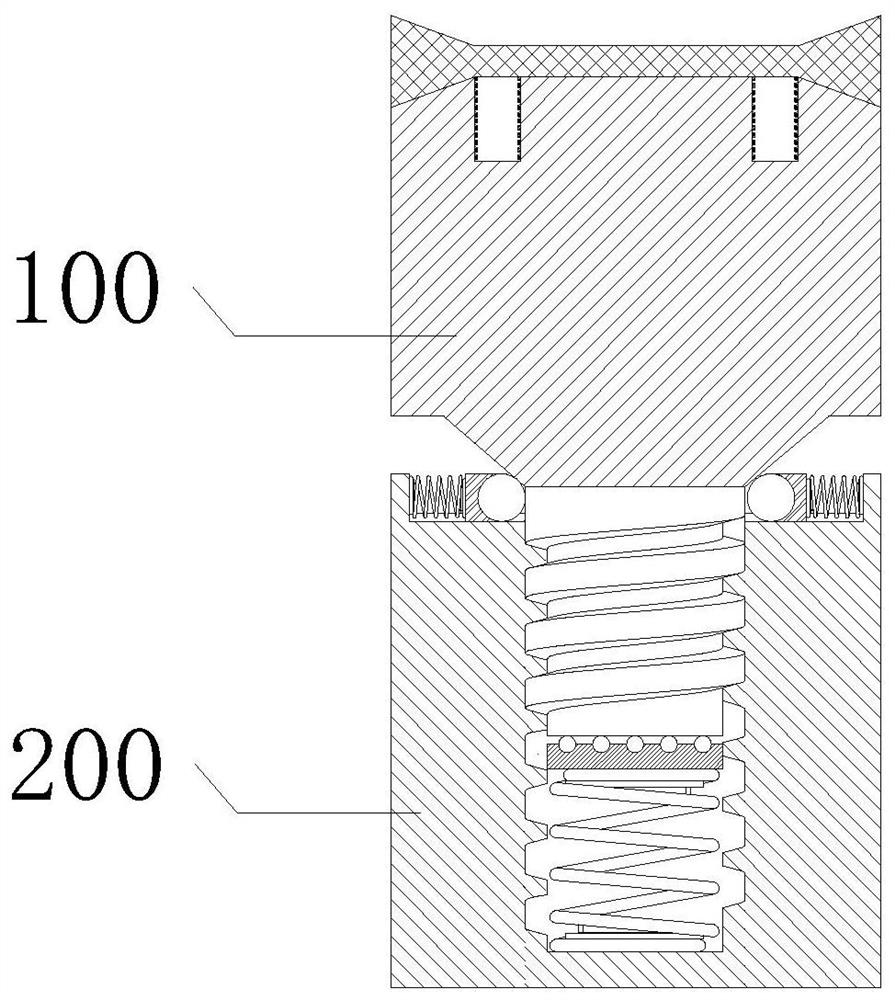

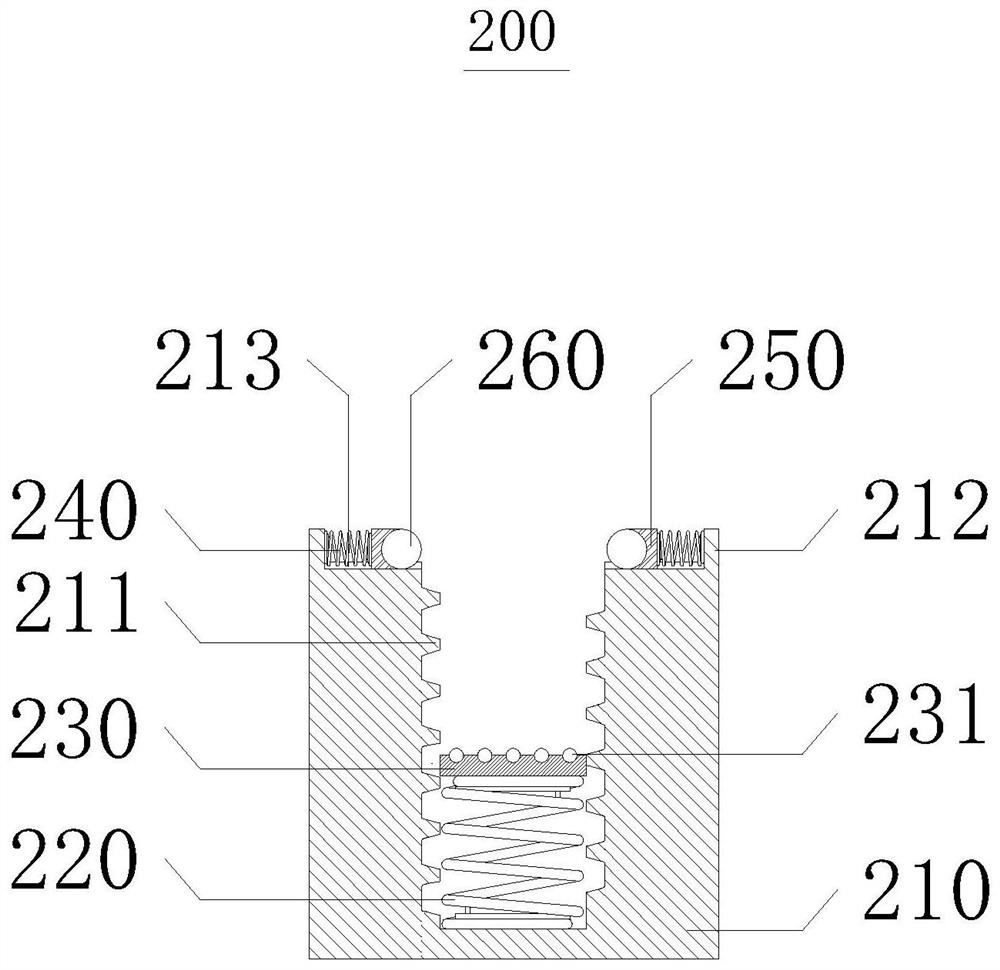

[0032] see figure 1 , the present invention provides a technical solution: a pressing tool for positioning pin sleeves, including a connecting mechanism 100 and a supporting mechanism 200 .

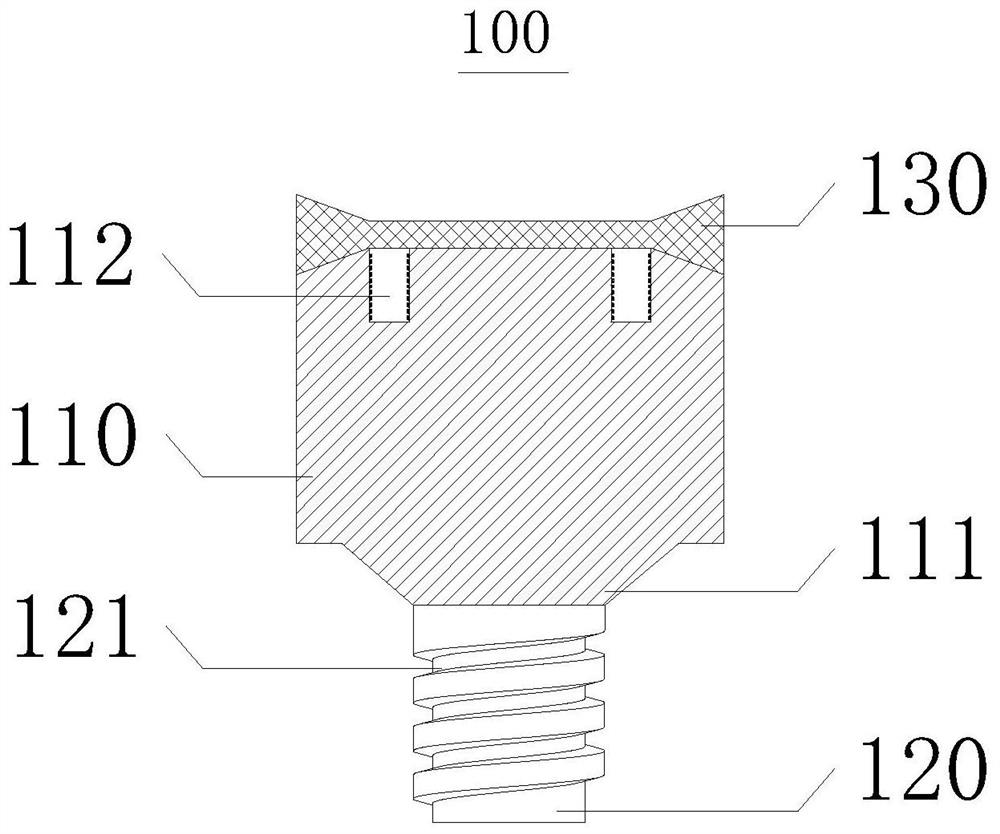

[0033] see figure 2 , the connecting mechanism 100 includes a connecting rod 110 and a screw 120 , the bottom of the connecting rod 110 is provided with a slide rail 111 , the screw 120 is fixedly mounted on the bottom of the connecting rod 110 , and the screw 120 is provided with an external thread portion 121 .

[0034] In some specific embodiments, the connecting mechanism 100 further includes a washer 130, which is arranged on the top of the connecting rod 110, so as to prevent the positioning pin sleeve from directly pressing the connecting rod 110 to cause deformation of the tool and affect the adjustment accuracy of the effective height of the tool.

[0035] In some specific embodiments, the connecting rod 110 is provided with a suspension hole 112, and the suspension hole 112 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com