Mold capable of adjusting elasticity on line

A technology of mold and elasticity, applied in the field of molds that can adjust elasticity online

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

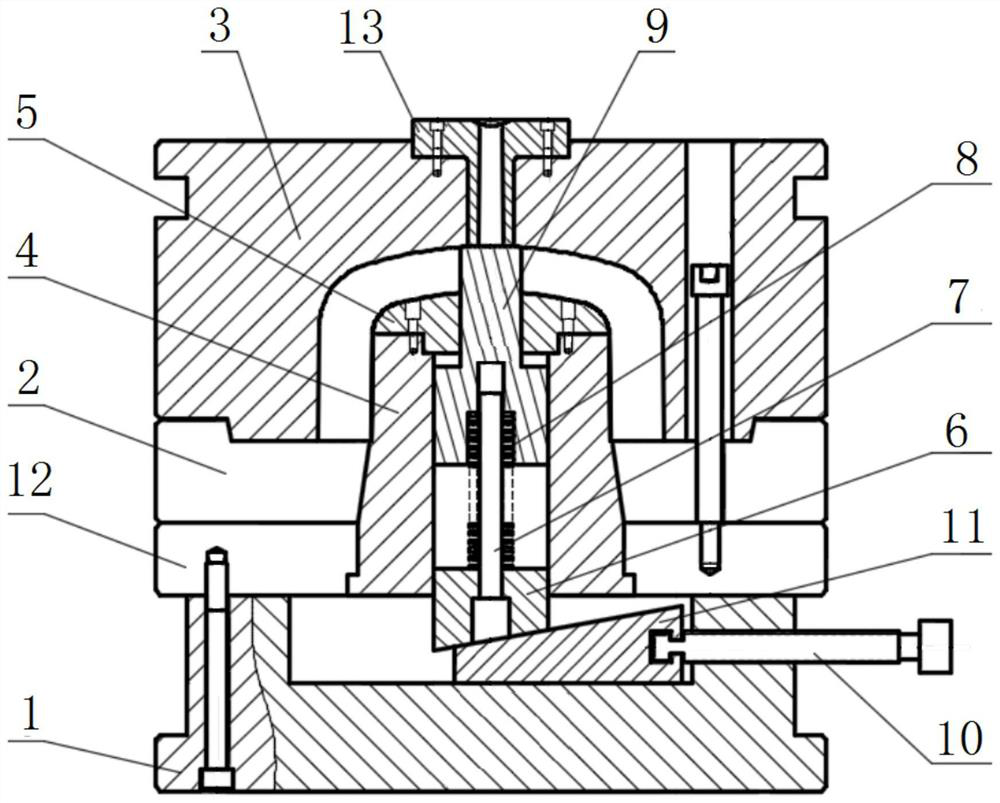

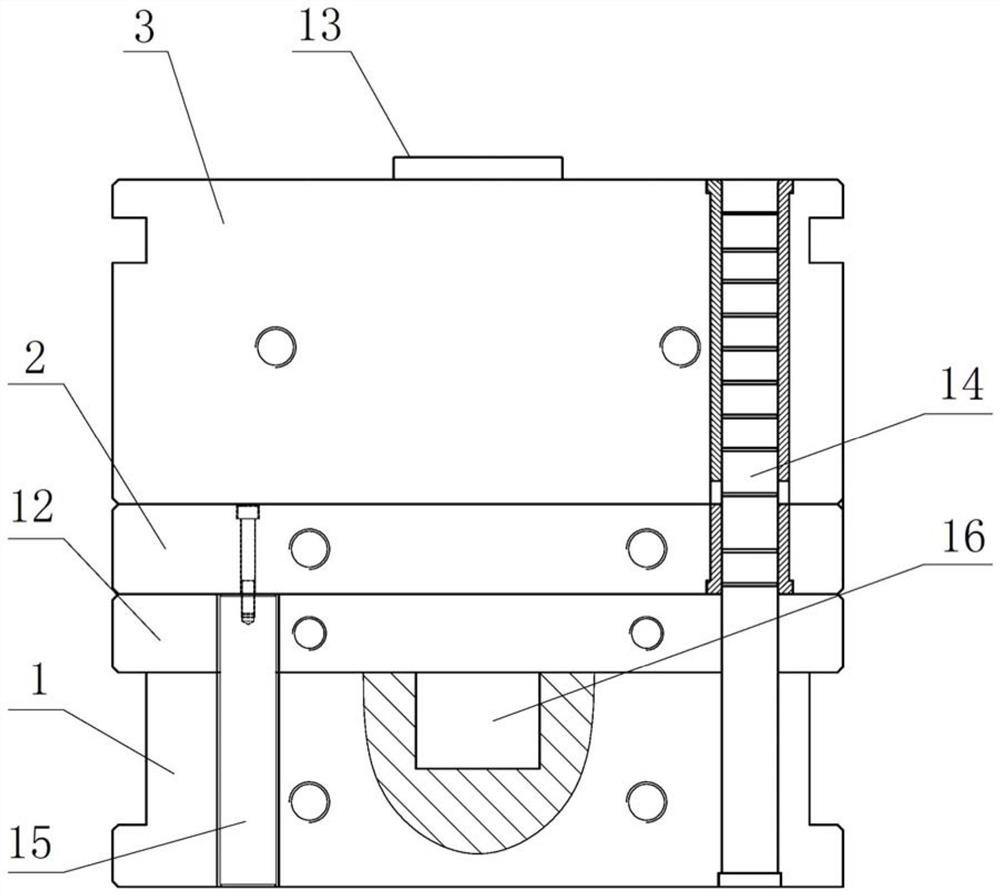

[0030] Such as Figure 1-2 As shown, a mold that can adjust the elastic force online includes a support 1, a push plate 2, a fixed template 3, a core 4 and a core cover 5; the push plate 2 is arranged on the support 1, and the fixed template 3 is arranged on the push plate. On the plate 2, the core 4 is set on the support 1, the core cover 5 is set in the cavity of the push plate 2 and the fixed template 3, the core 4 passes through the push plate 2 and is connected with the core cover 5, and the core 4 The inside of the core 4 is a hollow structure, and the inside of the core 4 is provided with an elastic mechanism. The support 1 is provided with an adjustment mechanism that cooperates with the elastic mechanism. mechanism, the other end of the elastic mechanism is against the glue inlet of the sprue sleeve 13.

[0031] In the present invention, when injecting pipe fittings, the injection molding machine melts the raw materials, and applies a certain pressure to send the mel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com