An auxiliary runner structure to prevent deformation of injection molded products

A technology of injection molding products and auxiliary flow, applied in the field of injection molding process equipment, can solve problems such as affecting the assembly of assembly parts, prone to distortion and unqualified size, etc., to protect bump damage, improve shrinkage deformation, and improve structural strength and rigidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

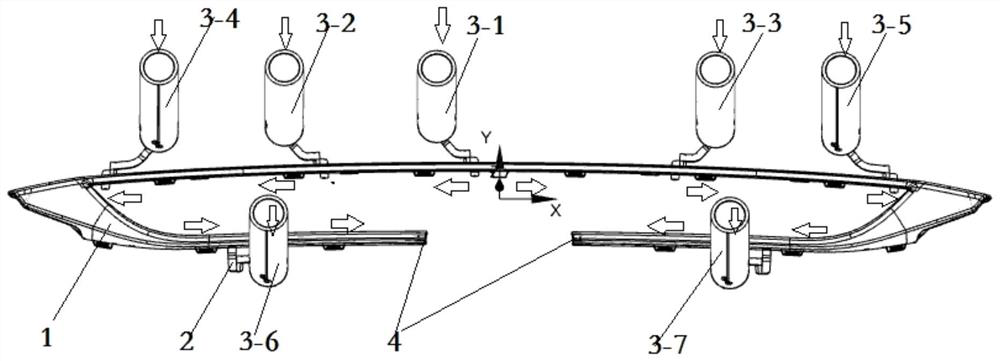

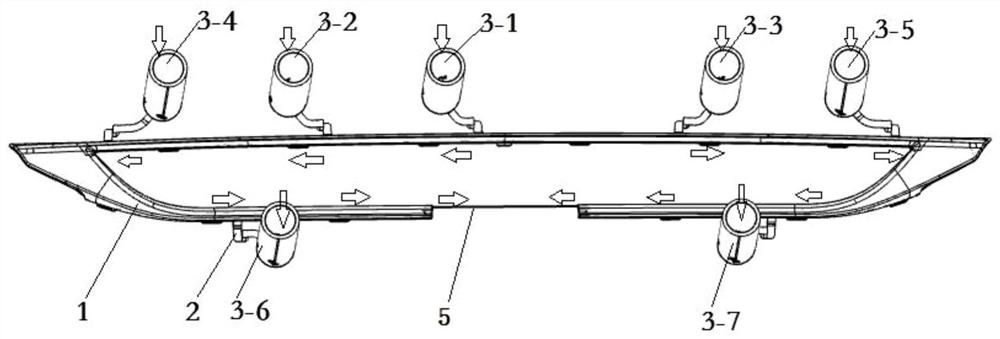

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

[0025] Some existing products have high requirements on appearance. During the injection molding process, the pressure-holding effect of the product at the end of the flow is not ideal, even if the pressure is maintained, the plastic cannot be filled to the end of the flow for feeding. How to solve the shrinkage deformation of the product at the break has become the key to the injection molding process of such parts.

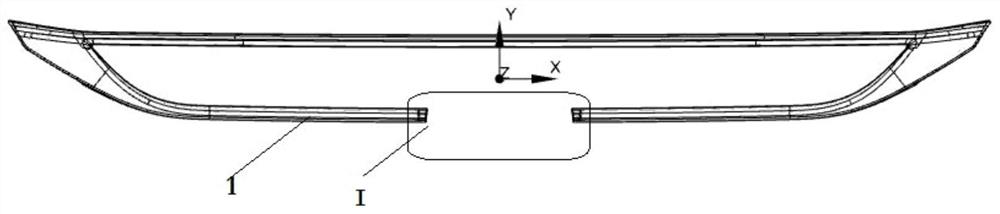

[0026] Such as figure 1 The product 1 in the prior art shown, the outer surface is the appearance surface, and the bottom is the non-appearance surface. After the injection molding production, it needs to be electroplated, and the I place is disconnected, which is the flow end of the product during injection molding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com